Craft beer production, and in particular the decoration of beverage cans, continues to face increased pressures. This is due to minimum order quantities having risen dramatically, with the increased use of shrink sleeves and labels used to decorate them, negatively impacting the environment and the aluminum recycling process.

Unsurprisingly, companies like Worthy Brewing with its ‘Earth First, Beer Second’ motto are looking for environmentally friendly solutions to get products to market quickly and move away from the use of plastics and adhesives. Direct-to-can digital printing is proving to meet these environmental demands and boasts a wealth of other benefits including a new level of design freedom and no minimum order quantities (MOQs).

Oregon-based Worthy Brewing is a sustainability focused, solar-powered brewery. The company has implemented various green initiatives in recent years and recognizing that there’s always a need to do more, recently turned its focus to beverage can decoration.

“We were facing the reality of order minimums and looking for alternative options that would allow us to increase our small-run seasonal package presence at retail,” comments Dustin Kellner, Brewery Operations Manager, Worthy Brewing Co. “We had tried both shrink wrapped cans and pressure sensitive labels on blanks and disliked both due to the downstream issues of recyclability.”

After exploring various options, Worthy Brewing contacted Solucan, a Canadian beverage can printer dedicated to providing craft brewers and brands with the ultimate beverage can supply chain flexibility required in today’s competitive market.

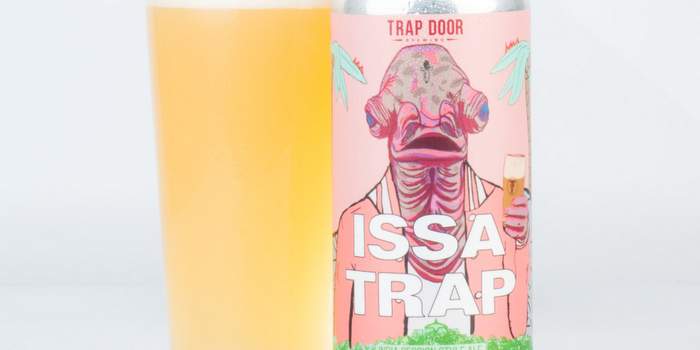

“Solucan offered a competitive solution that addressed all our recyclability concerns, while also providing a superior finished product,” Kellner added. “Utilizing the Solucan service, our can designs are also no longer hindered by numbers of colors or the degree of design complexity or detail – their service offering, powered by the Tonejet Cyclone, has transformed our go to market opportunities.”

Worthy quickly realized they could now meet production challenges head-on and open new business opportunities. Direct-to-can digital printing technology has enabled Worthy to respond quickly to changing trends and unique sales opportunities – providing the freedom to explore other products, with new sales outside of the traditional craft beer market in non-alcoholic beverages.

Worthy brews six signature year-round craft beers, in six designs produced every two to six weeks. It also brews a variety of seasonal beers, leveraging Solucan’s totally customizable digital offering for its packaging – which provides greater versatility in the number of SKUs, as well as removing minimum order constraints.

“Worthy quickly realized that we could meet their production requirements. A sizeable craft brewery, the company were ordering truckloads of cans sourced from one of the largest can providers, but this was resulting in huge inventories and cash flow issues. The introduction of digital print for beverage cans for Worthy has provided a sustainable solution enabling a more dynamic supply chain and revolutionized the way they do business,” said Sebastien Baril, President at Solucan.

Solucan prints directly onto 355ml and 473ml cans using its Tonejet Cyclone and Tonejet Cyclone C4+ pallet-to-pallet decoration lines. The Tonejet Cyclone models offer a total system approach that enables customers to work with cans from any source. Using a combination of digital printing inks and industry standard over print varnish, Tonejet printed cans have a better look and feel than traditionally printed cans and remain 100% recyclable without the use of any plastics or adhesives to maximize the full-circular recycling of aluminum.

“Craft beer has always been a huge potential market for our technology. Worthy Brewing understands the importance of can design while being conscious of the environmental impact of its packaging – something we are ideally suited to deliver,” added Rob Day, CEO at Tonejet. “Solucan has excelled in its mission to support the beverage industry as it moves away from plastic packaging, and the variety of customers they are producing cans for speaks volumes for the Tonejet technology and its capabilities.”

Leave a Reply

You must be logged in to post a comment.