With more craft breweries than ever before, competition between brewers has never been hotter. As a craft brewer, you want to expose as many types of your beer to as many craft beer drinkers as possible. One of the growing packaging trends is putting together a variety pack that serves as a brewery showcase. But where do you begin? Climax Packaging Machinery shines a light on the process.

You’ve likely already completed the first step, and that’s deciding between bottles or cans. While bottles have been the traditional choice for craft brewers, with roots in homebrewing, cans are becoming a popular alternative. It’s going to come down to what is the best choice for your brewery for both economic and presentation factors. Once you have made your selection, it’s on to the case.

The beer case

There are a million different cases, pack patterns and flavor mixes to choose from and the process can be overwhelming. This is the tipping point for most breweries, where they will either choose to go forward or throw their hands up in the air and give up pushing their potential variety pack profits out the door. But talking with the right people can speed up this process and make your variety packing headaches go away. Let’s take a look at the options:

There are a million different cases, pack patterns and flavor mixes to choose from and the process can be overwhelming. This is the tipping point for most breweries, where they will either choose to go forward or throw their hands up in the air and give up pushing their potential variety pack profits out the door. But talking with the right people can speed up this process and make your variety packing headaches go away. Let’s take a look at the options:

Top Load Case: For example, Sierra Nevada: Fall Pack Seasonal Sampler

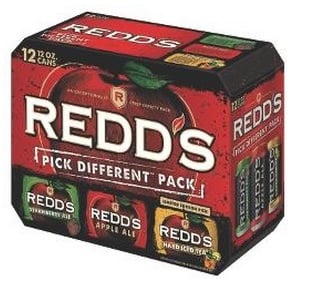

Side Load Can Carton: For example, Redd’s Pick Different Variety Pack

How to create the variety pack

This would have been an easy question to answer 10 years ago, but times have changed and companies have options.

Option 1: Hand picking beer. Most people think that this is the cheapest option. Well, not exactly. Let’s take a look at the basic costs of running a beer hand packing operation packing 2.5 million cases per year. What does it cost? Climax Packaging Machinery explains: You will need to hire 30 people. Estimated at $2,000/employee that you hire. These employees will work 40 hours/week and work 260 days a year. Estimated wages: $624,000 at $10.00/hour. In this example, the brewery or co-packing facility has spent more than $700,000 and that’s not considering workers compensation claims, insurance, employees quitting or any of the other numerous factors that can come into play.

Option 2: Climax Packaging Variety Pack “Rainbow” System. With the ever-growing popularity of variety packs, Climax developed the “Rainbow Solution” to meet the demands of today’s market. The Climax Rainbow Solution is a fully integrated system of product conveyors, uncasing, single-filing conveyors, lane dividers, star wheels, dividing wheels, packing and sealing equipment.

The Rainbow Solution can produce variety packs consisting of two, three, four, five or six individual flavors/types into a 12-pack or 24-pack, or most any other combination that may be required at speeds up to 25 cases per minute. If you don’t need that kind of speed, Climax also has two other designs that can produce up to seven or 16 cases per minute that are a little easier on your budget as well.

Blake’s Hard Cider Co. liked this on Facebook.