The Pacific Northwest is the birthplace of the American craft brewing movement. Regional craft breweries produce between 15,000 and 6 million barrels of beer per year. These breweries are unique because they take the time to create handcrafted brews with high-quality ingredients that would be too time-consuming or expensive for commercial breweries to produce. The downside of this specialty approach is that craft breweries seldom have the resources to invest in their own canning equipment.

In 2012, Justin Brandt founded Northwest Canning, a mobile canning operation based in Portland, Ore., that provides affordable packaging solutions for microbreweries and regional craft breweries throughout Oregon, Washington and Idaho.

Since its inception, Northwest Canning has experienced explosive growth, in line with the continued increase in craft brewing and has expanded its business from $100,000 in annual income to more than $1.5 million. To keep up with the increasing demand and sustain business growth, Northwest Canning examines its equipment and operational methods regularly to ensure it can continue to be “the fastest canning operation on the road.”

Pump selection is key to maintaining flavor and quality of beer

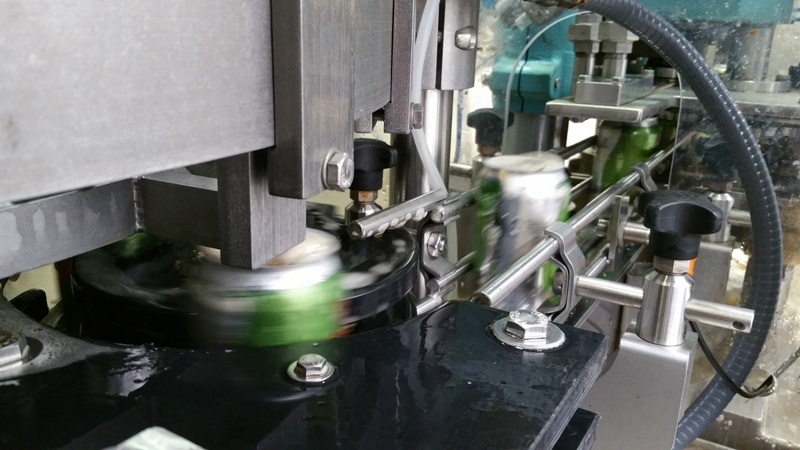

When Brandt started his business, his employees filled cans manually to serve the company’s small but growing clientele. As the client base expanded, Northwest Canning upgraded to an electric-powered centrifugal pump mounted in its mobile canning trailer. You might not think it, but its centrifugal pump provided a significant increase in power and required operation on a continuous cycle. The pump used an impeller to suck the beer in and then dispense it into the filler. The liquid was then transferred to 12- and 16-ounce cans. If the operation had to be stopped, the impeller would continue to spin, foaming up the beer in the filler and increasing the liquid’s temperature. The constant pumping of the beer introduced more oxygen into the beer, causing foam and ultimately killing the flavor.

“Brewers spend a significant amount of time hand-crafting their beer and take great pride in the ingredients they use and the flavor they create,” Brandt said. “Therefore, when it comes to canning, their biggest priority is that the flavor and quality of the beer are maintained.”

Because the centrifugal pump was powered by electricity to maintain its flow and pressure, it was a challenge to maneuver the trailer to areas that could reach power outlets at each brewery. In order to meet the output needed and maintain the quality of the beer, Northwest Canning needed to make a new pump selection. In early 2015, it replaced the centrifugal pump with an FDA-compliant, air-operated diaphragm pump from ARO.

“We had evaluated other diaphragm pumps, but they were inefficient and the air requirements were too high for some breweries,” Brandt explained. “We purchased the ARO pump because it was more efficient and most breweries could supply adequate air to run the pump.”

ARO’s FDA-compliant SD pumps are designed to transfer fluid for the food and beverage industries efficiently and safely. These pumps typically yield 20 to 30 percent better flow rates than other products available on the market, ensuring the material is transferred carefully — says ARO — a high priority for brewers and canners. Using the new ARO pump, Northwest Canning was able to manage the pressure more effectively to match other variables, like temperature and dissolved carbon dioxide in the beer. Operators are able to slow the flow rate if beer gets too foamy or increase it when needed. Since every ounce of beer is treated gently, the shelf life is extended while maintaining the carefully crafted flavor of each brew.

“We had evaluated other diaphragm pumps, but they were inefficient and the air requirements were too high for some breweries,” said Justin Brandt, founder of Northwest Cannery.

“A gentle canning process extends the shelf life of the canned beer while maintaining flavor quality — that makes my clients happy,” Brandt said. “When the canning happens quickly and at maximum capacity, I’m satisfied because I can get back on the road and serve more clients. With the ARO FDA-compliant pump, Northwest Canning is now the fastest mobile cannery on the road.”

Reliable pumping results in increased output and client capacity

Once Northwest Canning switched to an air-operated diaphragm pump, it was able to fill cans at maximum speed despite temperature fluctuations, distance from the tanks or other variables. With the centrifugal pump, Northwest Canning filled 100 to 120 cases an hour. Using the ARO pump, it now fills 160 cases an hour. Brandt estimates, on average, the company is experiencing a 10 to 15 percent increase in production capacity since selecting the ARO diaphragm pump. The consistency and the reliability of the pump also allows Brandt to better predict how long his team will spend at each client location, which ultimately translates into more bookings.

“Hauling the trailer across three states is a lot of travel time, so it’s important that we’re as efficient as possible. Now we can predict precisely where and when we’ll be at each client location,” Brandt said.

Today, Northwest Canning serves more than 20 different breweries and is producing 20,000 to 25,000 cases of beer per month. With seven full-time employees and additional part-time positions, the company is thriving.

“We look forward to growing our business and canning more beer in the coming years,” said Brandt.

Mark Jermeay is the ARO product manager for diaphragm pumps. This guy really knows his fluid processes, and we’re a little jealous of that.

Steve Parr liked this on Facebook.

Josh Allison liked this on Facebook.

Sean Barnett liked this on Facebook.

John Wanner liked this on Facebook.

How an ARO pump improves craft beer canning (a case study) https://t.co/rsAQ8IyePM via @craftbrewingbiz

#CraftBeer #CraftBrewing #Beer #BeerBiz How an air-operated diaphragm pump improves craft beer canning (a case … https://t.co/tBPjCtmRVY