Noon Whistle Brewing Co. was founded by three longtime friends — Paul Kreiner, Jim Cagle and Mike Condon — in 2014 after deciding that it was time to make their dream of starting a business together a reality. The brand’s name is reminiscent of an old town tradition where a whistle would signal workers to take a break in between shifts and enjoy a beer at noon. Paying homage to this tradition — which dates back many years — the owners set out to create sessional beers (lower than 5 percent alcohol content) that could be enjoyed with family and friends in a variety of settings over extended periods of time.

Despite facing several challenges along the way, including the realization that transforming a product into the best packaged version of itself can come with limitations, the overall process has been rewarding and serves as a unique example for startup craft brewers looking to follow suit.

From draught to can

After taking the first step toward their goal of creating different draught beer varieties and establishing their very own brewery, the Noon Whistle team began exploring the possibility of packaging their product. In 2016, the founders attended the Craft Brewers Conference in Philadelphia, where they were inspired by Sly Fox Brewing Co.’s cans featuring Crown Holdings Inc.’s 360 End. Based on the company’s philosophy of wanting their customers to enjoy their beer in various locations, this package seemed to be the ultimate fit for Noon Whistle.

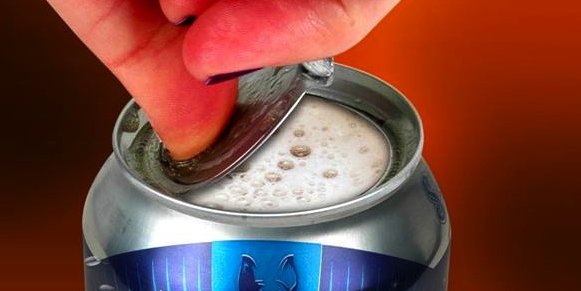

With Crown’s 360 End, the entire lid of the beverage can is removable, turning the metal can itself into a drinking vessel, eliminating the need for separate glassware or plastic cups that add unwanted waste. Ideally suited for the beer industry, the design of the 360 End enables the full flavor and aroma of the beer to hit the drinker’s senses upon removal, enhancing the overall experience with the product.

“This feature was particularly enticing to us, as it tied into our goal of allowing friends and family to enjoy our sessional beers at tailgates, in backyards or really wherever a separate glass for drinking is not readily available or practical,” said Mike Condon, Noon Whistle Brewing. “The technology would also provide our beers with a competitive advantage, allowing them to stand out on store shelves in what we consider a crowded market.”

Noon Whistle chose beverage cans as the package format for its beer due to their inherent barrier properties that keep the product in its peak state, along with other critical benefits.

“Beverage cans protect against light and oxygen transmission that could compromise the taste and quality of the beer. Cans also provide unique branding opportunities with their 360-degree billboard, which other package formats lack,” said Ron Skotleski, director of marketing for Crown Beverage Packaging North America. “The 360 End is a great example of how unique package formats offer a point of differentiation and enhance the consumer’s entire experience with your brand, adding value.”

Opening up a can of surprises

The Noon Whistle founders began researching the canning process and contacted Crown to get started on packaging their beer in aluminum beverage cans with Crown’s 360 End. However, the process came to a halt when the team discovered that Illinois had an environmental litter law in place that prohibited the production and sale of fully removable beverage container lids for beer, malt beverages, liquor and other products. The law was written in 1988 and at the time it was established, it did not particularly apply to the craft beer market.

Knowing this, Noon Whistle took it upon themselves to get the law changed to allow the 360 End in the state of Illinois. The brand claimed that other liquor beverages, which also fell within the prohibited category, were already using some variation of a completely removable lid on their package. The law was also out of date, as it was designed for a different era when different package formats yielded large amounts of waste. In addition, the company recognized that containers with removable lids might be subject to scrutiny if they contribute to package waste, but the 360 End, made entirely of metal, is 100 percent and infinitely recyclable and therefore could be responsibly recycled.

Noon Whistle enlisted support from a local state representative, the president of its brewing guild and other politicians. The state representative was instrumental in their quest to change the law to allow for this package type in the state. Noon Whistle provided input for their state representative to draft a bill and received additional support from the Illinois Brewers Guild. The craft brewers then pleaded their case before state senators and representatives. The final step in lobbying for the change was to have the law removed from the Environmental Protection Agency’s oversight and put into the oversight of the Tourism Hospitality Craft Industries group of Illinois. After about a year and a half, several meetings, and unwavering effort, bill HB2386 was passed.

“As craft brewers, we had to dust off our suits, plead our case to many different people and lobby for a change with the help of various governing bodies,” said Condon. “We were fortunate to have support from our State Representative Peter Breen, Senator Chris Nybo and the brewer’s guild. That aspect combined with our determination to have the 360 End applied to our package resulted positively for both us and our new and loyal customers.”

Moving forward, Noon Whistle plans to package all of its beers, including the non-session ones, with Crown’s 360 End.

“The tribulations we faced were well worth it,” said Condon. “Our customers repeatedly commend the package, citing that it is easy to open, easy to pour into a glass and even great to drink straight from the can, enhancing the overall drinking experience. Our distributors are also excited about its uniqueness in terms of marketability.”

“We encourage any craft brewers interested in the 360 End to reach out to Crown for more information or to seek support from their local representatives, as Noon Whistle did successfully,” said Skotleski.

[…] remove the entire top — as opposed to popping a small opening like you do with standard cans. The brewery had to fight for it though, advocating for changes to a 1988 Illinois law that prohibited the […]