New packaging equipment is being developed to help end-users with challenging carton profiles, stuff like beer baskets that showcase the expanding universe of craft beers, delicate cigarette boxes, the brave new world of marijuana packaging and even bottles made from completely recycled materials. Innovations like cloud-based data systems, increased auto setup options and the use of aerodynamic vacuum conveyors are just a few ways equipment makers are helping to increase packaging line speed and efficiency.

Difficult to manufacture carton profiles

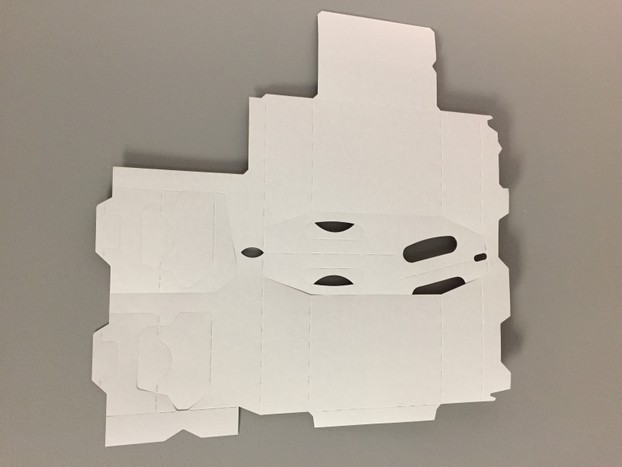

Origami may not be the term that springs to mind when thinking about cartons for your beer, but perhaps it should be. An unfolded six-pack beer basket begins its life unfolded and lying flat, coming to life after five to seven different folds (in two different directions). The folds make the intricate little panels that keep the bottles from clanging together and also create extra handle strength. Those nicks and folds that hold it together all take place in a line that can be running at speeds of 35,000 pieces per hour.

Some profiles are more difficult to design than others. Round profiles are among the most difficult. Working with circles throws industrial package designers for a loop. Engineers and box makers typically work in straight lines, with belts that fold and rails that register square edges, so equipment can run at high speeds without damaging packing. Registering around a circle can be challenging. WSI faced this challenge several years back when designing coffee cup machines. The coffee cups are made up of two pieces that are doubled and unfolded in a half moon shape. It was quite difficult to feed and accurately process the delicate shapes while running at high speeds. The solution turned out to be quite simple but took a great deal of time and energy to produce.

Beer baskets are another extremely challenging product; it takes special equipment to handle the complex shape and fold sequence. And those complex machines must be flexible enough to handle a variety of adjustments for different size and fold styles. The recent craft and microbrewery trend has added a wrinkle; the new generation of beer purveyors does not want the same beer basket as all their competitors. They want to showcase their unique brand, shaking up the packaging industry as they seek more highly styled, complex packages, with different shapes, handles or edges.

The systems that produce these types of baskets can run into millions of dollars and require a great deal of setup and expensive tooling. It can be a challenge to fold and glue those packages at a reasonable rate — even without throwing in the variable of a unique panel or a unique fold. The industry as a whole is facing an increasing challenging as it diversifies from a few large breweries to more than 5,000 smaller ones.

New products and industry trends affecting carton profiles

Newer recycle and reuse trends are also affecting carton manufacturing. Recycled board looks and performs the same as virgin board but warps easily and is more difficult to process. It may contain staples and nails. Most are removed, but smaller particles remain in the board and are quite abrasive, wearing down belts and surfaces more quickly.

Recycled materials in general require different packaging techniques, but now, innovative new packaging concepts require a whole new way of thinking. For example, some companies, like California-based Ecologic Brands, are producing liquid container packages for drinks and detergents. These packages combine a sturdy outer molded fiber shell made from cardboard boxes and old newspapers with a thin recycled inner plastic pouch and re-sealable cap. The recycled slurry is pumped directly into a molding process — and out the other end comes an environmentally “green” package. The challenge for packaging companies is dealing with this three-dimensional part shape, rather than the flat blank that has always been used in the past.

The package requires a series of cuts with extremely clean edges that are acceptable to consumers. The company had been using lasers to get the edge quality required. WSI recently developed a way to use conventional knives that make an excellent package at a much higher speed than the laser and with a much more reasonable cost.

New packaging technology innovations and process improvements

Several recent packaging equipment innovations are helping to meet the challenges identified. High on the list is the use of cloud-based data, which captures and records each package’s details during every run, if desired. The ability to barcode scan packages at any time to see all the pertinent data for that package, including where it was made, who set up the line and machine settings for every part of the machine, helps manage packaging and track quality control. It also provides data if there is ever a problem with the package.

End-users are also looking to become more efficient — to be more productive without the need for more manpower. Tying the processes of print, cut and finishing without labor is one way. Another is to automate and make the setup from one job to another as efficient as possible. Increased use of auto setup means end-users can store settings and utilize motors to react to those settings to perform operations very quickly and safely.

RELATED: Packaging on a budget: Four solutions your craft brewery should consider

Ergonomics has always been an issue but is becoming more important than ever. Why continue with a machine that requires an operator to lift and stretch and bend when a little out of the box thinking by the machine designer can make the lift motion a button push?

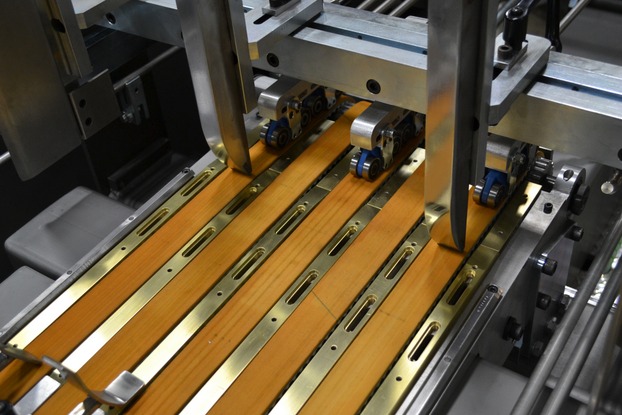

Finally, speed is king — end-users are always looking to run as fast as they can at the highest quality level. Machines that allow users to run substantially faster than the competition will increase profits. For example, as noted above, flat beer basket cartons are fed into folding machines and become a foldable package that has to hold together even when the machine is running at high speeds. This operation results in a great deal of wind resistance, and if even one panel flies up and blows back, the package is destroyed. This situation has been exacerbated by the fact that packaging companies are minimizing materials to reduce cost and are also using cheaper materials whenever possible.

In response, WSI has been developing a variety of more delicate handling techniques, including the use of deck plates, vacuum conveyors and other means of high speed transport of delicate blanks. For example, to enable speeds as high as 2000 feet per minute, WSI developed vacuum belt conveyors with an aerodynamic advantage that keeps beer basket cartons flat and in one plane. The equipment also uses a technique called lead lug positioning, which ensures exactly the right spot to marry the carton folds at high speeds.

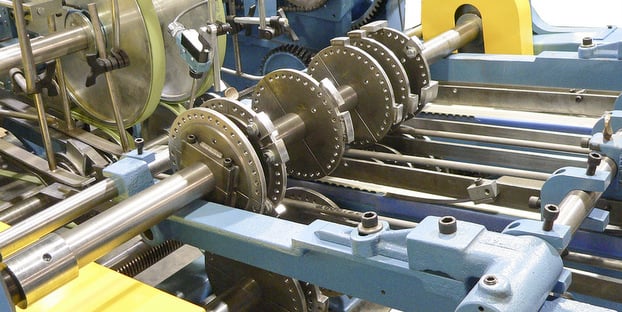

Another technique WSI has developed to deal with difficult to handle carton shapes is the use of pulse feeding, which, unlike conventional friction feeders, allows the blanks to sit flat. This causes much less interlocking of the intricate panels for 6-pack blanks and tobacco packages, which have a tendency to interlock or be easily damaged. Pulse feeding allows operators to set the blanks flat on the feed table. A servo drives a cam, which is used to raise the belt up into contact with the bottom carton and peel it off. The next carton is not exposed to friction and is also not being bent up in the air, which causes the interlocking.

Gaining – and maintaining – process control is the key to success

Packaging engineers all live by a credo: Once you have something under control, don’t let go of it. The concept simply means that when one keeps a process under control, one can handle it through the next process. The corollary is that if one process is not under control, others are unlikely to be.

As an example, some customers feed a blank carton out and do not register it to get it perfectly square. They then send it through another process where they will affix a label and send it through a vision system camera to inspect the label. Since it wasn’t square, the label will be off and the carton will be rejected. Now their scrap rate is through the roof! The very simple technique of registering and controlling one process earlier in the line would reduce their scrap rate to nothing.

Sometimes getting a process under control may require going back earlier into a line and adding a simple fixture to regain control. Other times it may take installation of an additional machine. But the bottom line is that registering systems eliminates many concerns. For example, many end-users’ systems use gluers with no registration features. They forego their last chance to make a great product. After spending so much time creating, printing and cutting with the best equipment in the world — they are finishing it with a low-end gluer? To guard against losing control at that last step, WSI developed gluer upgrade kits so end-users can keep their entire process under control, ending with square and perfectly glued cartons.

This insight was sent our way by Craig Jasper of WSI Global.

Leave a Reply

You must be logged in to post a comment.