The barrier that once existed between canned beers and craft beers has been torn down. Andrew McLean and Scott Richards, partners at Michigan Mobile Canning, noted that they had anticipated encountering some remnants of the old stigma that canned beer was cheap, low-quality beer, but that resistance wasn’t there upon starting their business.

“I was pleasantly surprised that people have long understood the huge advances in canning technology over the years, and now some of the largest, most respected craft brewers in the country are doing it,” McLean said. “Craft beer drinkers are a pretty well-informed group, and they understand all the benefits of cans. It’s better for the beer, with no light or oxygen hitting the beer. It’s better for the environment. It travels better. It gets cold faster. The benefits go on and on, and craft beer drinkers know it.”

What was once a taboo is now a trend. The sudden boom in interest by both craft brewers and craft drinkers in canned beers opens up new pathways for revenue. Jumping on this trend could increase interest in a brand by getting it in more hands and in more places, like ball parks and beaches and hiking trails, that bottles often cannot go.

But where there is opportunity, there are new challenges. Craft brewers, as innovative and entrepreneurial as they are, still have budgets, and often small budgets. Is adding a canning line to your operation worth the investment for a 500-barrel (bbl) brewer? When does the opportunity outweigh those risks? How can you capitalize on this trend without mortgaging your current business model?

Canned mobility

For craft brewers looking to have their canned beer and drink it to, mobile canning might be the answer. Much like mobile bottling, these services are full-service, providing all the equipment, supplies, planning and expertise that goes into putting your beer into a tiny aluminum package.

“This allows the brewers to focus on their beer, and we’ll take care of the rest,” McLean said.

Michigan Mobile Canning is part of the growing network of mobile canners affiliates of Mobile Canning Systems, the brain child of Pat Hartman and Ron Popma. The story goes like this: Hartman and Popma migrated to Colorado from Philadelphia. They traveled seeking corporate America positions, but the siren song of the craft beer industry was just too alluring. Hartman went to the University of California Davis extension for a week-long brewing school to enhance his skills with his sights set on opening his own brewery, but during that time he started to talk with more and more brewers about packaging ideas.

“I saw there were a lot of them using mobile bottlers, but I started thinking that cans were actually the better package for craft beer, and now breweries are migrating there at a staggering rate – so why not mobile canning?” he asked.

That was the Eureka moment. He and Popma met up with the team at Wild Goose Canning and worked out the kinks of getting canning equipment into a properly sized truck and by fall 2011 they were ready to roll. Crabtree Brewing was their first customer, and now demand is so hot in Colorado they are bringing a second truck online. In addition, the Mobile Canning Systems model itself has gone mobile.

“We knew that it was going to work; we knew we could replicate our model, but how do you hire guys from a remote perspective? It’s such a hands-on, intimate business with brewers, beer, equipment that remote managing didn’t make sense,” Hartman said.

In October 2012, the company launched the Mobile Canning Systems affiliate program. That aforementioned growing network of Mobile Canning affiliates is now at seven affiliates that cover all or parts of: Alabama, Connecticut, Georgia, Indiana, Los Angeles, Massachusetts, Michigan, New York, Ohio, Tennessee and Virginia. The affiliate program helps an aspiring mobile canner set up a business by providing information on what to buy, what not to buy, help source the equipment and go through a full training program. The affiliate program also adds to the collective benefit of all involved as the larger group can buy bulk quantities and lower costs overall.

“Can manufacturers like to sell truckloads of cans, and they have high-speed equipment that it makes sense at those volumes,” Hartman said. “Starting out as a mobile canner, you don’t have that. You have a large capital investment, logistics and storage issues, and we are able to now help with that as we come together.”

McLean, who is able to serve all of Michigan, as well as northeastern Indiana with Richards, said the only real limitation of his operation is the drive-time to get to the brewery in the first place.

“We anticipate ordering a second truck and line within 12 months, allowing us to keep trucks in different parts of the state, lessening the drive-time between jobs,” he said.

I don’t know — Can you?

For Mobile Canning Systems, the process begins with the labels. First-time orders are scheduled about four to six weeks ahead of time to allow for label approval, printing and application to the cans. The company uses a unique plastic-sleeve label that wraps around the can. This enables all parties to avoid the bulk orders required in pre-printed cans and allows Mobile Canning to provide custom labels in the smaller batches – a benefit for small and large brewers alike.

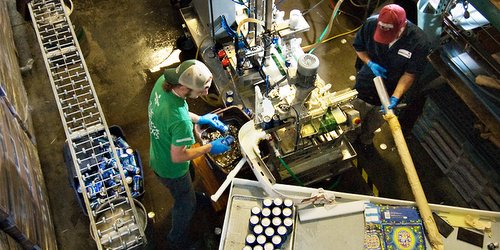

“Once that’s set, the brewer just lets us know how many barrels and when he wants us there,” McLean said. “We arrive on-site, unload the equipment and supplies, including the pre-labeled cans, and get to work. When we’re done, we load everything back up, and the brewer is left with pallets of cans to sell and we’re out of their way until next time.”

The equipment and process usually handles about 25 to 35 cans a minute, depending on whether it’s a 12- or 16-ounce run. There is the full-service option where Mobile Canning supplies everything, including the pre-labeled cans, can tops, four- or six-pack holders and cardboard flats. If a brewery is looking to hit retail with a lot of cans, the company can also provide an option where the brewer purchases a bulk order of pre-printed cans and Mobile Canning would arrive to simply provide the canning services.

The only potential restriction is the on-site layout, McLean said.

“While the line has been specially configured to be mobile, we still need to be able to get the line at least somewhat near the beer,” he said. “There aren’t too many locations we can’t reach, but that’s a consideration as we’re meeting brewers and touring their facilities. However, as we told them, if you want your beers in cans, we’ll figure out a way to make it work. When there’s beer to be had, brains can get pretty creative.”

Can you dig it?

For those in the decision-making process, here are some of the reasons mobile canning might make sense for your operation:

- For a 500- to 600-bbl brewery, the costs of adding a canning line might not be justified, especially if you are only canning every other week or so.

A canning line “is a big asset to be sitting there, but also the inventory as well, having to sit on a truckload of cans,” Hartman said. “It’s a lot of capital and space if you are only making 1,000 bbls a year, and a portion of it is in cans, you can go through a truckload of cans, but it will take you five years. And that’s just one label as well.”

- The economies of scale and the lower order counts can allow a brewer to be more nimble and experiment with a variety of new/existing/seasonal brands in cans. This is where that shrink-sleeve labeling comes in handy.

“A shrink sleeve allows you to work with the smaller volumes that make sense for a brewery that’s decent size and wants to make a seasonal,” Hartman said. “We can run 15,000 cans at a time without breaking the bank. So still within numbers where the brewery is still going to be able to make some money off what they are doing.”

- Mobile Canning customers do span a variety of breweries – from 500 bbls to some as large as 40,000 bbls. Maybe you have a canning line already that you use regularly to run your flagship brands, but when you are ready try out a new seasonal, it might be more efficient to bring in a mobile operation for a day to handle it while your main lines stay on stride.

Bottom line is cans are on the rise, and it make sense to explore all of your options in order to efficiently grow your business and satisfy your customers.

NonstopExpo says

Amazing article about Craft canning lines ! Complementary equipment is also published on http://www.nonstopexpo.com.

RT @CraftBrewingBiz: Craft canning lines brought straight to your brewery door. Does it make sense for your business? http://t.co/DwlRCZeVLC

RT @CraftBrewingBiz: Craft canning lines brought straight to your brewery door. Does it make sense for your business? http://t.co/DwlRCZeVLC

RT @CraftBrewingBiz: Craft canning lines brought straight to your brewery door. Does it make sense for your business? http://t.co/DwlRCZeVLC

RT @CraftBrewingBiz: Craft canning lines brought straight to your brewery door. Does it make sense for your business? http://t.co/DwlRCZeVLC

RT @CraftBrewingBiz: Thanks to @mobilecanning and @MIMobileCanning for their insight on the mobile canning trend #craftbeer http://t.co/Dwl…

RT @CraftBrewingBiz: Craft canning lines brought straight to your brewery door. Does it make sense for your business? http://t.co/DwlRCZeVLC

Thanks to @mobilecanning and @MIMobileCanning for their insight on the mobile canning trend #craftbeer http://t.co/DwlRCZeVLC