The can packaging debate is pretty much over in the craft beer industry. Across the country, more and more brewers are ramping up canning lines and producing a variety of unique aluminum-packaged beer products that are seeing increased exposure and popularity on store shelves and in beverage coolers.

“There’s no more questions like: Should we consider cans?” explained Brian Thiel, Craft Brand Manager for CROWN Beverage Packaging North America,one of the country’s top metal packaging solutions providers. “Those questions have already been answered by the brewers. Decisions have already been made that this is the right package, and what I’m seeing now for common trends is that both new and old breweries are coming to us with multiple can designs and can labels. They’re packaging several different brands. I’ve even had customers start with five or six brands right out of the gate.”

There are many pros to cans. They are lighter weight, less expensive, more resistant to sunlight and hermetically sealed so no oxygen can contaminate your delicate and delicious beverage. Cans also provide niche distribution opportunities — in sports venues, concert halls, public facilities and events that don’t allow glass bottles. Plus, cans just have that adventurous, portable quality to them. If you’re canoeing, camping or climbing to the top of Mount Everest, a can of beer is usually the packaging option of choice.

Don’t get us wrong. Glass packaging still remains supreme and boasts incredible popularity with today’s breweries and customers, but cans are a game-changer with a lot of interesting options and price points. With the craft canning industry hitting a high point, Craft Brewing Business decided to sit down with Thiel and Crown to discuss the evolving can packaging market, detailing these five important tips and trends that craft brewers should consider when choosing a particular can, can design and can supplier.

No. 1: Brand vision

Did you happen to see the bowtie-shaped aluminum can that Budweiser released this past summer? It re-envisioned the company’s iconic bowtie logo into can form. It’s a very well thought-out example of capturing a brewery’s image and voice with a can design. It’s an option called shaping. High-tech blowforming technologies can allow for the production of essentially any can shape — from subtle to highly innovative asymmetrical designs. It’s just one of many options (from promotional ends to unique finishes) that craft brewers can choose from, but before we get started with those, what do you want to say with your can size, shape and design?

“What’s their vision for their packaged can products?” Thiel asked. “This is their brand, their billboard, going out into the market, so what do they want that particular billboard — aka, the can — to say to customers?”

It gets into the DNA of brewers and their brands. What type of customers are you trying to attract, and how will your brand and identity change to meet the requirements of this newly packaged product you’re selling? Craft brews each have their own individual flavors and personalities, and these are often reflected in the distinct imagery and logos on the containers themselves. Lots of options are available to differentiate your brand, but even a good product needs to be matched with a well-thought-out identity or those extras and options become meaningless.

“Plus, you must understand that these options will add cost to the overall can,” Thiel said. “So, understand the message the brewery is trying to portray with this particular can. I think understanding that will help guide them toward what options are best for their cans.”

No. 2: Size does matter

In mid-October, we saw Mission Brewery become the first U.S. microbrewery to release 32-ounce cans. These 32-ounce “cannons” of Shipwrecked Double IPA and El Conquistador Extra Pale Ale entered seven new states in December. Whether seeking a can to accommodate a smaller serving size, a slim can for a light product or larger sizes for high volume consumption, can suppliers can deliver a variety of packaging size solutions. The majority of the market still uses 12-ounce cans, but what about tall boys, quart cans and everything in between?

“I’m having conversations weekly on different can sizes — even outside the traditional 12- and 16-ounce can sizes,” Thiel said. “We have some examples in the beverage industry where different segments have started out in a particular size — specifically I’m talking about the energy drink segment. If you go back in time, those products started off in 8-ounce or in some cases 7.5-ounce or 8.4-ounce cans. If you look at any convenient store right now, you’ll see that the shelves are dominated with energy drinks packaged in 16-ounce cans, even up to 24-ounce cans. So, whether the craft beer market will follow the same trends, well, there’s certainly been some indications that there is a big interest level for larger can sizes like the 19.2-ounce imperial pint can and the 32-ounce can that some breweries are starting to package in.”

An important question should be what beer bodes well in different can sizes. Mission Brewery won’t agree, but other breweries might not think a double IPA may be necessarily the best choice for the larger can size, especially with a higher ABV. We’re seeing anything from pale ales to stouts being put into aluminum cans. It’s across the board, but right now, two main can sizes still rule the market.

“The 12-ounce is still the predominant size on the market,” Thiel said. “But the 16-ounce can has shown some tremendous growth throughout the last few years.”

If you had to choose, would you be in a 12- or 16-ounce can? That’s a difficult question because often the driving force for can size comes down to owner preferences.

“For instance, I have one brewery in the Seattle area that has stated to me, ‘I can’t see my product in anything else but a 12-ounce,’” Thiel said. “I posed that same question to another customer who only packages in 16-ounce, and I got a similar response. ‘This is a true pint. Why would you put it in anything else?’”

Outside of personality and preference, there are still some regional mindsets that might dictate can size. We don’t want to over-generalize this topic, but there are certain regions that seem to support certain can sizes more. “The South tends to gravitate to a 12-ounce can, while the 16-ounce can is more widely accepted throughout the West,” Thiel said.

We encourage readers to look at the variety of can options that Crown offers.

No. 3: Well-prepared designs that are already approved

Graphics should be considered pretty early on in the process. For craft brews, perhaps more than other canned beverage industries, the graphics and images associated with a particular beer are important. The good news is that brewers can certainly achieve a level of artwork and image quality on metal cans that is similar to that on printed labels, but the design process is going to be different (surface area, inks and finishes for starters).

“There are options available in terms of novelty inks and different varnishes to create different effects on the can such as tactile or a matte finish,” noted Thiel. “All of those things are options, but again, in my opinion, the best graphic designs seem to be the ones that have a cohesive message in terms of presenting straightforward messaging to the customer.”

Come prepared to work through several iterations if necessary to achieve the final design. It’s an important process, and one that shouldn’t be hurried. Look for a supplier that offers a complete process for customers to set up and execute trial print runs for approval before going to press. At the same time, there’s a lot to be said for involving the supplier on your end wherever possible, and ideally, at the start of the artwork creation. They tend to have a lot of experience in both design and printing, which should translate to consistency and accuracy for brewers.

“I always advise my customers if they want to understand what they’re asking to be printed or created on a can label is to make a mock-up of the can,” said Thiel. “Take it to a place that sells aluminum can products — a supermarket or a beer store — put it on the shelf and step back about 4 feet and take a look at it. See how that design, that concept, bodes for the consumer who will be standing in the same position and making a decision to choose that beer or something next to it.”

A critical step that we advise is for brewers to understand both federal and state regulations for labeling in terms of the Alcohol and Tobacco Tax and Trade Bureau (TTB) and other local and state regulations. Feel free to peruse the TTB’s many regulations.

“If they need TTB approval or they have certain regulations in their state or approval processes they need to go through, we require that those be taken care of,” said Thiel. “That significantly reduces the amount of rework that we have to do down the line.”

The traditional “lithography-style” graphics setup process is fairly detailed. Most can manufacturers must go through a similar process to take artwork and prepare it for metal decoration. Usually, that process starts with color separations, which are still handled by human beings, so there’s a time factor involved with that. Obviously, they’re working closely with computers, but the core of the work is handled by a specialist, a person that is actually separating all the colors available on the artwork and applying things in the industry that are called “staybacks” of “cutbacks” that basically keep the ink from contaminating into each other.

“From there, the customer plays a crucial role throughout the setup process,” said Thiel. “There are certain electronic and physical samples that the customers will have an opportunity to review and approve before going onto the next step. So the process does take time, so that’s another thing that a new customer would want to take into consideration. Typically, I’m quoting new customers that from the time Crown approves the artwork, it’s typically a seven- to eight-week process to get through the graphics setup.”

How does the actual printing work? You can learn how cans are actually made, but after the aluminum coils are cupped, trimmed and washed, they are dried in preparation of the application of internal coatings and labels. This is pretty much in the middle of the can manufacturing process. Basecoats can be used if required, which would then send the cans through a basecoater oven to cure. Then, printers using up to six colors of ink print the labels on the cans and then apply a thin film of lacquer over the entire label to protect it. The process is intricate, but this excellent chart should help even new brewers understand the ins and outs.

There are, of course, different types of printing options, and we’ll discuss those below.

No. 4: All those interesting options

“We have customers that take a relatively simplistic approach to graphics on their cans. Others go the route of a very intricate, well thought-out design. It’s almost like a piece of artwork,” said Thiel. “We can handle those graphics from all points in between, and that’s one of the things that I’m very proud about the work we do with our customers from a graphics standpoint, helping assist them in developing their brand and what their brand message is.”

The options abound. Creative colors and designs strengthen brand recognition and heighten consumers’ interests, and craft brewers can take advantage of a variety of unique decorative tactile finishes to make sure beverage cans have just the right look and feel. Here’s a selection from the Crown website.

- Glow in the Dark: Light sensitive finish adds a fun and interactive element to beverage cans.

- UV Light: This special ink reacts with black light, helping designs stand out in bars, clubs or discotheques.

- Pearlescent: A shimmering varnish that brings depth and sophistication to designs.

- Interference: This color-change ink switches between two hues when cans are rotated.

- Soft Touch: Matte finish gives cans a premium look and satin-like feel over the entire can.

- Matte: Provides same results as Soft Touch, but is used in distinct locations on the beverage can.

- Tactile: Lends a unique “wet look” to cans.

- Thermochromic: Changes color to inform consumers when beverages have reached optimal temperature for consumption.

Promotional ends are becoming more and more popular as well — just check out our article on the 360 End. Different end and tab alternatives provide additional pop at the point of purchase for craft brewers. Identity ends, colored tabs, laser-etched tabs and full-aperture ends can all be designed to complement various marketing activities — promotional messaging, instant win campaigns or just enhance overall brand appeal.

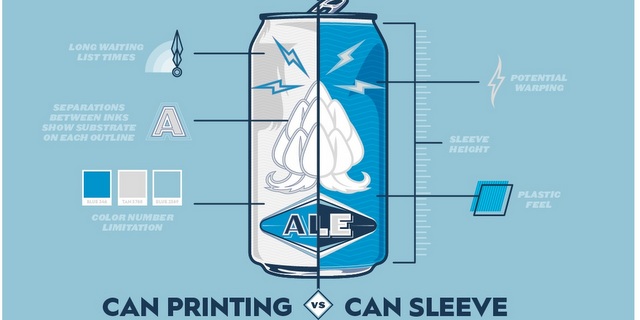

There are different types of printing and labeling options as well, besides the traditional lithography printing described above. Sleeves and digital printing have become interesting alternatives. Shrink sleeves are a type of labeling application in which labels are printed on film and shrunk tightly to conform to various shape and size containers (including craft cans). They often span the container’s full 360 degrees, from top-to-bottom, providing marketers an enormous canvas in which to display powerful point-of-sale graphics and content. Read our article on craft beer sleeve choices.

Traditionally, lithography printing was the only option for true printing on cans. It has its pros and cons. Lithography printing means large minimum orders and long lead times, but also high-quality artwork. But there have been some advances in digital printing technology now, making it possible to produce highly-decorated aluminum cans in economic order quantities. Ball Corp. seems to be the big player in that market. This is how the company compares the two:

- Digital Printing delivers high-quality presentation for small volume orders and limited edition tins. Setups are very quick, allowing for fast delivery.

- Lithography is for custom tins that require exact color match and precise designs. Printing costs go down as order volume increases.

Besides printing choices, end options and sleeve alternatives, multi-media innovations like QR codes, stickers and collaborative marketing campaigns are creeping into the craft canning market. In November, Ore.-based Fort George Brewery announced a seasonal brew called Tender Loving Empire NWPA (Northwest Pale Ale). The beer promotes Tender Loving Empire, a consignment shop, screen printer and record label representing artists in the region. The cans feature a sticker with a special code for free downloads of music from artists on the Tender Loving Empire label. The partnership took it one step further with the production of four music videos that were filmed on the Columbia River from Portland all the way to the canning line itself.

“We’re seeing more and more examples of that over the last few years,” said Thiel. “Breweries are interested in working with other breweries either in their general area or sometimes across the country, collaborating not only on the beer itself, but also the packaging. That’s a really interesting concept. It’s a trend I’m particularly interested in, and I’m seeing more and more of that with our customers. And it’s not just breweries. It’s collaborating with businesses. In my opinion, one of the key components to the growth of the craft industry in general is community and local-ism.”

No. 5: Partner with an ideal supplier

When transitioning to a completely new packaging format, it’s vital to establish partnerships with suppliers as early on in the process as possible. It’s important to emphasize the value of face-to-face interaction with your can supplier. Wherever possible, brewers should try to arrange on-site visits to their supplier’s operations. In fact, any good partner will encourage this, especially at the start of a new business relationship or for the initial run. These visits will help brewers better understand how the supplier’s processes and systems work in relationship to their own. The supplier should also know the canning industry overall.

“If it were me, I’d want to feel comfortable working with a supplier that has a broad understanding of the market we’re in — speaking specifically with craft,” explained Thiel. “One of the things I pride myself on is educating and understanding what’s going on around me. And what I mean by that is I formed some really great relationships with other vendors and other suppliers that are really in the same line of business, but doing something different to support aluminum can packaging. That could be canning machinery suppliers, secondary packaging suppliers, even down to who’s manufacturing the basic cardboard case trays — things like that. I like to consider myself that one-stop shop when it comes down to it.”

The right supplier should also understand that it’s an ongoing partnership. They should provide contacts for technical support that brewers can communicate with regularly — not just in an emergency — if any questions or issues come up. Good technical support is not just about fixing something when it’s gone wrong. It’s about providing regular guidance on topics that brewers may not be familiar with, such as full can handling, seaming and graphics.

“It’s about commitment,” said Thiel. “Your suppliers should not just be in this industry to take a piece of the increased volume. Like Crown, we’ve been here. We’ll continue to be here, and we’ve got the commitment throughout the organization to grow that business here.”

From turnaround times and minimum runs, a good supplier should be there to answer all your questions and concerns about producing the ultimate canned craft product. And there are also a ton of general resources, including associations, trade shows and sites like Craft Brewing Business that focus on the metal packaging industry and can provide supporting info. We’ll keep you updated on all of those fronts throughout the year.

RT @CraftBrewingBiz: Five keys to choosing the right can and can supplier for your craft beer. http://t.co/7EGQu3oyoQ

There are many pros to using cans – Here are the 5 Keys to choosing the right can and can supplier! http://t.co/DVstL2iVaM

RT @CraftBrewingBiz: Five keys to choosing the right can and can supplier for your craft beer. http://t.co/7EGQu36paI

RT @CraftBrewingBiz: Five keys to choosing the right can and can supplier for your craft beer. http://t.co/7EGQu36paI

@CraftBrewingBiz Very useful tips. Cheers for 32oz. cannons! Thanks for sharing and happy President’s Day.

RT @CraftBrewingBiz: Five keys to choosing the right can and can supplier for your craft beer. http://t.co/7EGQu36paI

RT @CraftBrewingBiz: Five keys to choosing the right can and can supplier for your craft beer. http://t.co/7EGQu36paI