Since its humble beginnings in the 1930s, beverage can technology has advanced both in popularity and development to become a proven format to hold and preserve drinks ranging from beer to sodas to energy drinks and beyond. What is it about beverage cans that make them a go-to format among consumers?

Many craft beer brands cite the can’s inherent durability as an ideal fit for consumers who enjoy active lifestyles and want to take their favorite drinks with them without the risk of the container breaking. Other sources suggest that convenience is a strong factor: cans chill faster and stay colder longer than other packaging. Environmentally conscious consumers might speak to the ease with which aluminum cans are able to be recycled thanks to the curbside recycling programs established across the nation.

The basic format of the beverage can has been around for almost 80 years, but the technology continues to evolve as brands seek opportunities to introduce innovations that spur new drinking occasions and reach new market segments. Recent innovations have varied in complexity, ranging from the shift of three- to two-piece beverage cans in emerging markets to the increase in the production of specialty cans in mature markets like the United States.

In addition, consumers may not even be aware of all the innovations that have been introduced, such as the latest advances in lightweighting. For example, how many beer drinkers would know that the weight of aluminum cans has been reduced by 30 percent over the past 35 years, providing both logistical and environmental savings?

Most of the advances made in recent years — like lightweighting, shaping and decorating with high-definition graphics or tactile finishes — have been focused only on the body of the can. But as brands continue to look to packaging suppliers like Crown for new ways to succeed in the crowded retail landscape, new developments in end technology will continue to emerge and enhance the convenience, ease-of-use and drinking experience. Let’s take a look at three recent innovations in end technology that are enhancing the consumer experience.

Intuitive Opening

Ease of use is a major driver for innovation as consumers continue to seek solutions that offer added convenience. For busy, on-the-go consumers, the can must always be easy to open, and that action of opening the can must be instantly intuitive for them to perform.

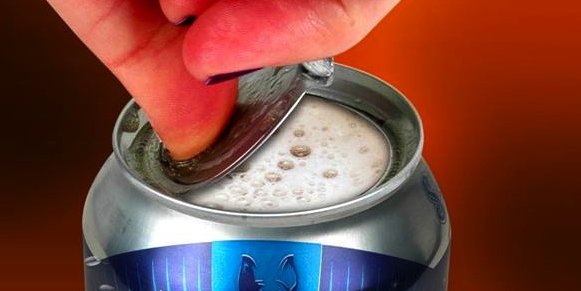

There is a certain something to the click and hiss of a can opening that consumers love. At Crown, we are constantly striving to enhance the opening process and make it easier. That meant looking at what additional functionality could be incorporated into the standard method of opening a can, which ultimately led to the development of the Crown Global Vent — a dual aperture end that facilitates a smoother pour directly from the can. This new end features two holes, rather than the single hole featured on standard ends — a design that improves airflow and allows consumers to enjoy their drinks with less foam.

Some solutions that try to mimic this functionality require additional opening tools, such as a churchkey, to puncture the second aperture. Others solutions situate the second opening directly underneath the pull-tab. In contrast, the Global Vent needs no tools and its second aperture is situated in the 2 o’clock position (relative to the rivet of the tab) specifically to prevent accidental puncture. Instead, consumers simply rotate the pull-tab and press down on it to open the vent.

Enhancing the Beverage

Innovative technologies can also enhance the drinking experience for consumers while simultaneously enabling brands to move into markets and venues where the beverage can is not a typical option. This has most recently been the case in the rapidly expanding craft beer industry through the adoption of the 360 End. A combination of Crown’s food can and beverage can technology, the 360 End can be completely removed, eliminating the need for separate glassware.

For beverage brands — and brewers in particular — the 360 End allows consumers to fully enjoy the drink right from the can. The effort and time that brewers spend developing the aromas for their beers is considerable, and by removing the entire end of the can, the full flavor of the beer hits the drinker’s senses right away. Debuting in 2010 at the FIFA World Cup in South Africa, the full aperture end was used by China in 2012. The 360 End debuted in North America with craft beer brand Sly Fox Brewing Co. and continues to prove popular with craft brewers, most recently with Texas-based Four Corners Brewing Co.

This same technology also makes the can an even more appealing package for outdoor activities, including events or concerts. In stadiums, vendors are traditionally required to physically open each can and pour its contents into a plastic cup before passing it to the consumer. Not only does this create a new source of waste, but it also results in losing the branding and marketing of the can. With the 360 End, the can itself becomes the cup that consumers take away with them, speeding up service time, eliminating additional waste, and enhancing marketing possibilities and brand exposure. The new end has already seen successful adoption for Sly Fox’s Pikeland Pils, which was served exclusively at Citizens Bank Park, the home of the Philadelphia Phillies, in 2013.

Increasing Convenience

According to a report released by Packaged Facts at the end of 2012, packaging attributes that consumers value most include resealability and ease of opening/closing. Convenience packaging has long been needed to match the on-the-go demands of our increasingly busy lifestyles. As a result, brands are looking to packaging suppliers for solutions that are designed to meet the needs of an increasingly mobile marketplace.

For the beverage industry, the concept of a reclosable can has always been considered the holy grail of package design, but reaching that goal was a challenge for designers and manufacturers alike. From a design perspective, it can prove difficult to bring new functionality that is intuitive to use without adding 1) significant weight to the lid and 2) costs for manufacturing. Although various solutions have been presented over the years, they have typically proven too technically complex and economically unworkable, particularly in terms of integrating them into filling lines that have now been standardized internationally.

Fortunately, this is no longer the case. First introduced in Europe in 2013, Crown’s XO Reclosable end features a simple two-step operation that creates an airtight seal every time the tab is re-closed, offering enhanced convenience and product protection for on-the-go consumers. Opening the end is easy and intuitive: the consumer simply lifts the tab at the back of the can to open the vent seal and then slides the rest of the tab backward to reveal the drinking aperture. Reversing the process recloses the can, giving consumers the confidence that their beverage and carbonation will be safely contained and preserved. We began showcasing the XO Reclosable end to brands across North America this year, most recently at the Craft Brewers Conference.

Developed in Europe by XOLUTION GmbH, Munich, Germany, and produced by XO’s production partner ALPLA, the Crown XO Reclosable end is also easy for brands to implement. With minimal adjustments, fillers can run the end on existing lines, and it uses standard seaming equipment. This prevents the need for any significant investment or additional changes through the supply chain.

In a saturated market, sometimes the simplest changes to a package can make all the difference. This is why the beverage end is going beyond simply being employed as a tool to seal cans. Whether it enhances the drinking experience, adds convenience to consumer lifestyles, or simply makes it easier to drink our favorite beverage wherever — and whenever — we want, the beverage end is now helping brands evolve and expand their reach. The end is just the beginning.

Jan Dunphy is the vice president of sales and marketing at Crown Beverage Packaging North America.

RT @mrbrewreview: 3 can technologies that could change the craft beer industry http://t.co/4SaB5yHMaf via @craftbrewingbiz

3 can technologies that could change the craft beer industry http://t.co/4SaB5yHMaf via @craftbrewingbiz

RT @brewbia: http://t.co/e4LaFtmyFL @CraftBrewingBiz those cans are legit!

Dustin Young liked this on Facebook.

Glass Bottle Outlet liked this on Facebook.

Brewers Professional Alliance liked this on Facebook.

Jones’ Farm- Home of Bad Bunny Hops liked this on Facebook.

RT @CraftBrewingBiz: Crown discusses three major can technologies that are changing the craft industry. http://t.co/cRwwKHsX1i

http://t.co/e4LaFtmyFL @CraftBrewingBiz those cans are legit!

RT @CraftBrewingBiz: Crown discusses three major can technologies that are changing the craft industry. http://t.co/cRwwKHsX1i