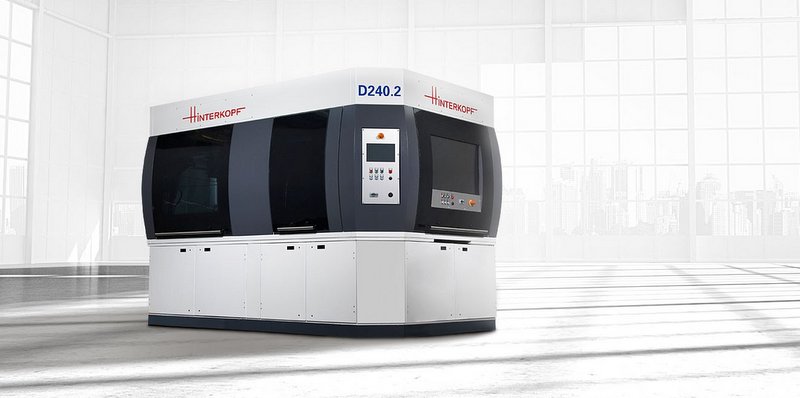

Eastside Distilling’s Craft Canning + Bottling is a premier mobile packaging provider on the West Coast, with locations in Oregon, Washington and the Front Range of Colorado. Its service offering is going up a notch after securing this rare German-made printer for its custom canning operation. The new printer, the Hinterkopf D240.2, is the only one of its kind on the West Coast and one of ten in the world. The new acquisition gives Craft Canning the ability to offer a ton of flexibility for breweries, cideries and wineries looking to directly print on canning projects of all sizes. The new printer will be in operation starting April 1, 2022.

“Craft Canning’s success has been built on helping breweries and beverage producers expand into professionally packaged products. Our new printer is the next phase in a series of additional services we are providing to expand our top-quality canning services for beverage producers of all sizes,” explains Bill Anders, Eastside Distilling’s Business Unit Manager of Can Printing. “As we have done with our mobile canning business, being able to offer can printing with low MOQs will make can printing accessible to smaller producers as well.”

In anticipation of the printer’s arrival in March, Bill Anders and Michael Stout, Eastside’s Engineering and R&D Manager, trained at Hinterkopf’s factory in Germany. Craft Canning also hired a new designer devoted to can printing, and to maximize the printer’s technology and features.

Advantages of the Hinterkopf D240.2 include excellent printing quality and performance, with resolution of up to 1200 dpi. It can create photorealistic images with millions of colors and subtle shadings. It offers total, seamless ink coverage of the can, with the finest gradients and shading, optimal edge definition of lines, and pin sharp text.

The printer also optimizes workflow: it is completely digital, maximizing production time and providing cost advantages. Selected images are directly printed onto the can, and any edits and changes are performed at the push of a button. The change-over time involved with conventional printing methods can be avoided.

The Hinterkopf D240.2 does all of this while driving improvements in sustainability. Direct printing onto cans eliminates ink waste and cleaning agents. It inks only on the end product so there is no misprinting, which cuts down on the production of unusable cans. The low minimum order requirement also translates to a production with no surplus, saving about 600 million cans worldwide. Whereas cans that have adhesive labels can only be recycled after removing the label, cans produced using this new print technology are easy to recycle.

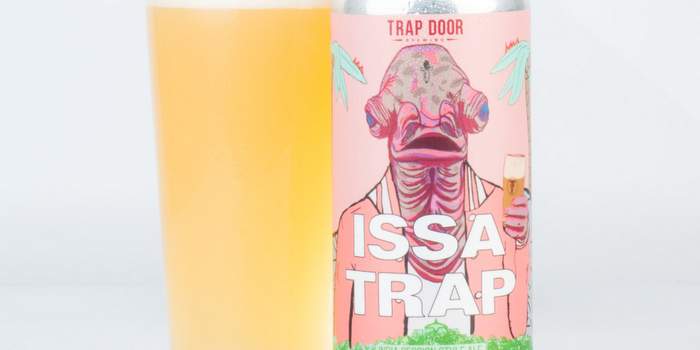

The Hinterkopf D240.2 printer will give Eastside Distilling’s Craft Canning the ability to offer unparalleled customization and flexibility to its customers. Craft Canning will print 12-ounce or 16-ounce cans in any quantity with any image, with a minimum order of 400 cans. This flexibility allows for custom graphics of limited releases, vintages, partnerships, and special events.

Leave a Reply

You must be logged in to post a comment.