Edinburgh Beer Factory is benefitting from improved codes, reliability, and ease of use from the The CSL30 laser coder from Linx Printing Technologies.

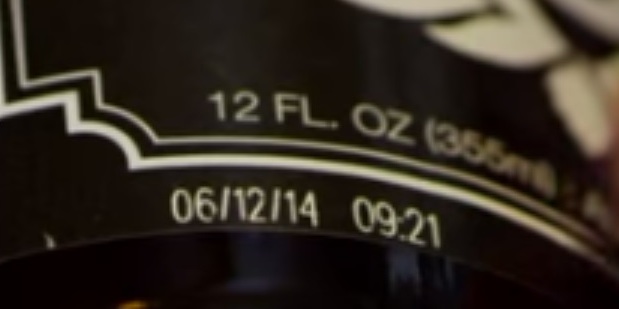

Edinburgh Beer Factory currently uses the Linx CSL30 to code ‘Best before’ dates and batch codes on its automatic bottling line, which processes around 2,000 330ml bottles per hour right now, but the Linx CSL30 provides room for growth with the potential to handle more production and new bottle sizes.

“For various reasons, our original coder for batch and date codes wasn’t quite right for us,” explains Martin Borland, Head Brewer at Edinburgh Beer Factory. “We started looking into alternatives and laser technology fitted the bill, with Linx offering the most competitive price as well as a turnkey solution. The price quoted was what we paid.”

Established in 2015, Edinburgh Beer Factory is a family-run, independent brewery and has already grown to more than 20 employees in its three years of business. Taking inspiration from the Pop Art philosophy of using unsung objects to create art, it takes overlooked beer styles and presents them at their beautiful best.

Since it is a laser coder, the CSL30 uses no ink and as a result there is no drying time involved or risk of smudging – problems the company found with its previous coding solution. The codes from the Linx are super legible and always appear in the same position on the bottles.

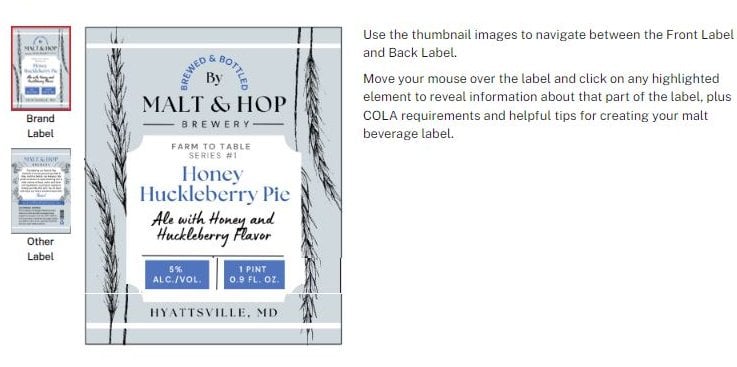

Also important has been the Linx CSL30’s large, color LinxVision Touch Screen, which makes operation intuitive, leading to fewer mistakes and ensures adjustments can be easily carried out in a matter of minutes.

“We can turn it on, type in the details, press start and forget about it all day,” Martin said. “When you process 2,000 bottles per hour, you need to be confident that your BBEs and batches are being printed, and the Linx coder gives us this. Everything we wanted – cleaner codes, more reliability, the potential to grow – we now have. It’s even more cost-effective than our previous coder.

“Most importantly, we’re now confident about the future because we know the machine can go faster if we need it to, and from running successful trials, we know it works well on larger bottle sizes too,” Martin continued.

Linx Printing Technologies is a global supplier of continuous ink jet (CIJ) printers, case coders, laser coders, thermal transfer printers and thermal inkjet printers.

Leave a Reply

You must be logged in to post a comment.