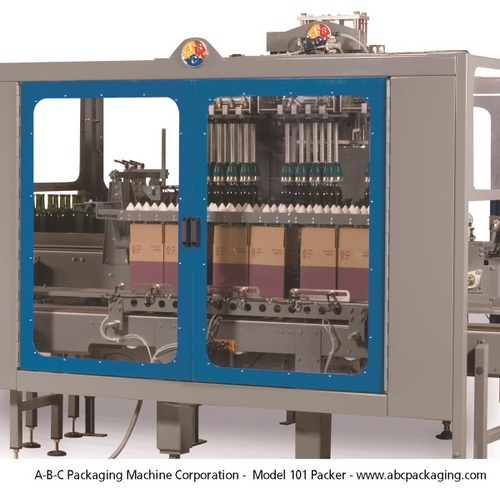

Craft breweries looking to run multiple sizes and packs of bottles should consider the quick-change features of the Model 101 case packer. According to A-B-C Packaging, the Model 101 can reduce downtime up to 30 percent compared to conventional changeover practices.

This packer is designed with complete gripper assemblies for all pack/bottle patterns that each packager requires to eliminate time-consuming gripper adjustment, and guide rail placement is simplified with sliding and locking handles to allow quick adjustment to the new specification. In three steps, the changeover is completed:

This packer is designed with complete gripper assemblies for all pack/bottle patterns that each packager requires to eliminate time-consuming gripper adjustment, and guide rail placement is simplified with sliding and locking handles to allow quick adjustment to the new specification. In three steps, the changeover is completed:

- Unbolt and replace the gripper assembly,

- Slide product guide rails to new settings,

- Select the new container style at the operator control panel, which activates the proper machine actions for the new product/case handling.

Setup testing is virtually eliminated, further reducing changeover downtime.

The Model 101 packs glass and plastic bottles, jugs, jars and specialty shapes, as well as metal and composite cans and many styles of cartons. The servo-driven pick-and-place operation ensures gentle product handling to maintain container and label integrity, and containers are packed under full control from the conveyor to the shipper. From lightweight glass bottles to heavy, industrial-sized containers, the Model 101 packs with gentle precision.

Todd Parker liked this on Facebook.