Brewhouse technology provider Precision Fermentation unveiled BrewIQ this week, which is the next generation of its fermentation management solution, formerly known as BrewMonitor. BrewIQ gives brewers real-time visibility into fermentation, process automation with event-driven alerts for quickly addressing problems, and the ability to analyze data for more efficient, consistent and profitable production at scale.

“Brewers today face higher ingredient and labor costs and thinner operating margins,” says Jared Resnick, CEO of Precision Fermentation. “With real-time data and the tools to glean valuable insights, brewers can overcome these challenges and turn out consistent, high-quality products more quickly to improve product quality and consistency, and drive profits. BrewIQ is the result of input from hundreds of breweries of all types and production levels.”

The smarts of its engine come from the years of data and learning. BrewIQ has the benefit of using data from more than 250 breweries and nearly 5,000 fermentations.

BrewIQ features

New features of BrewIQ are aimed at shortened fermentation cycles and reduced costs.

BrewIQ Fermentation Hub. This connects to any tank and measures seven critical fermentation elements simultaneously, in real-time.

Fermentation data is stored in the cloud and easily accessed from anywhere, at any time, via a mobile device or desktop computer. In addition to WiFi connectivity, the BrewIQ Fermentation Hub now supports Power over ethernet, eliminating the need for additional power sources. .

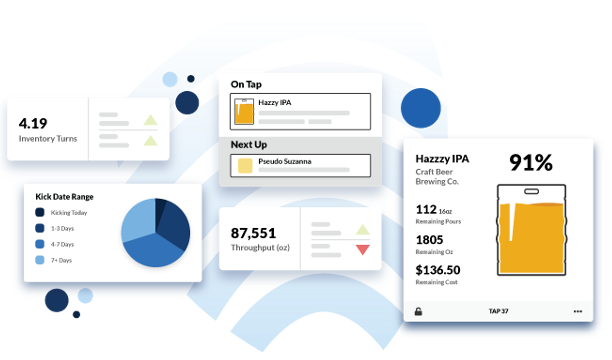

BrewIQ Dashboard. This dashboard deploys new adaptive analytics and benchmarking capabilities to give brewers precise insight into fermentation events and anomalies as they happen.

BrewIQ SaniStation. This is the new CIP station that cleans up to four Fermentation Hubs simultaneously. Brewers can manage active cleaning cycles with the click of a button through that BrewIQ Dashboard, where cleaning logs are also stored for FSMA compliance and historical analysis.

All in, the company claims that BrewIQ delivers a return on investment in four to six months. But don’t take their word for it:

“BrewIQ has helped us dramatically improve our output,” said Sassan Mossanen, co-founder and CEO of Denali Brewing Company. “The ability to collect, access and analyze real-time data has incredibly beneficial for our brewery, and the new BrewIQ SaniStation has cut our cleaning and sanitation cycles dramatically, which allows us to work more efficiently and speed up production.”

Leave a Reply

You must be logged in to post a comment.