Pearson Packaging Systems, provider of turnkey end-of-line packaging solutions has released a packer with the craft beer space in mind: The BL60 Close-Coupled Beverage Line. The focus is reliable operation, compact footprint and flexibility to grow with manufacturers over time.

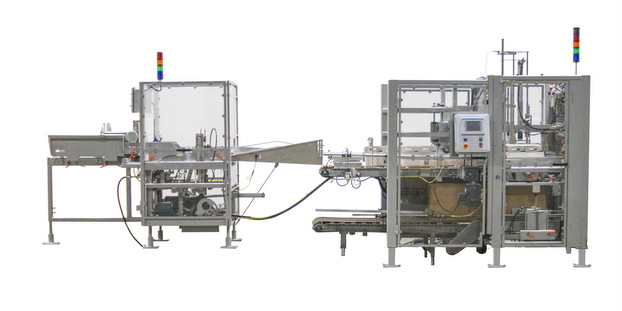

The line combines Pearson’s core BE60 Carrier Erector and MP35 Multi-Packer with slight redesigns for an all-in-one solution. The Carrier Erector forms 4-pack or 6-pack carriers which are packed into RSCs, HSCs or trays by the Multi-Packer at rates up to 60 carriers and 15 cases per minute.

The machines are connected by a twin lane conveyor. An air knife lane diverter eliminates part wear and potential failure associated with mechanical lane diverters to increase overall equipment effectiveness (OEE). Additionally, the BL60 is simple to operate with a basic operator station and PanelView HMI and easy access for clearing jams and completing other maintenance tasks. The line is ruggedly built to last decades when properly maintained.

At only 19’ in length, the BL60 saves valuable floor space compared to Pearson’s original beverage line without sacrificing reliability. Pearson Product Manager Jim Thompson says, “Small footprint solutions are a necessity in small facilities where square footage is often limited.”

“We expect our customers – especially mid-size craft brewers or companies that are new to automation – to find the maintenance and labor savings, as well as the versatility of this line particularly valuable. It’s not uncommon for craft brewers to invest in solutions only to find that they will no longer meet their needs a few years down the road. With the implementation of a dual carrier erector, the BL60 line is easily scalable to grow right along with the demand for our customers’ products.”

Leave a Reply

You must be logged in to post a comment.