Following the choice to embrace solar power, construction involving reinforcement of the roof at NewAge Industries’ headquarters began in the summer of 2010. It culminated on June 8, 2011, when a group of the plastic tubing manufacturer’s employees flipped a switch and began using solar energy. The power system, consisting of 4,082 rooftop solar panels, has the capacity to produce up to one megawatt continuously and has been doing so for the past ten years.

“It was our most ambitious project to date,” said Ken Baker, the company’s CEO. “As a U.S. manufacturer, we insisted on U.S.-manufactured products – the solar panels, the racking system that holds all the panels, the inverters that convert the electrical current – and it took a lot of research to source everything.”

“We place a high value on being a responsible manufacturer,” Baker continued, “and we’re thankful for the amount of electricity the system produces. It’s great to be helping the environment and our community.”

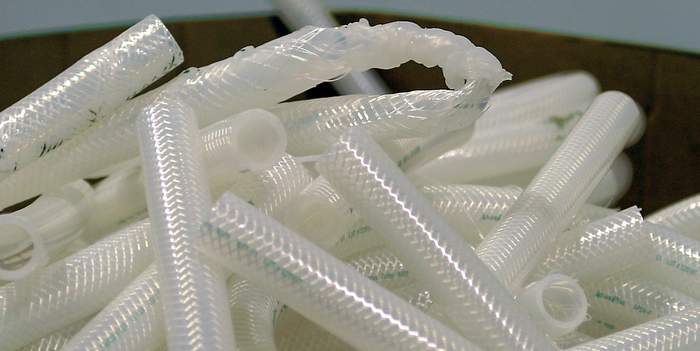

NewAge, which manufactures Single-Use molded tubing assemblies used in vaccine production, in addition to plastic tubing, made the switch to solar power in conjunction with several other green initiatives. The company replaced outdated warehouse lighting with energy efficient styles, upgraded manufacturing motors and equipment, installed screens on dock doors to increase ventilation and reduce exhaust fan usage, replaced the building’s windows, sealed warehouse floors to eliminate concrete dust and dirt, and reorganized its waste disposal to include recycling, compacting and a zero landfill strategy. Collectively, the improvements helped the company reduce operating costs while improving its sustainability.

The solar energy system originally contributed more than half of the energy needed at NewAge’s headquarters. Expansions at the facility have since increased electricity needs, but the company is proud to be harnessing the sun’s energy and putting less pressure on the community’s power grid.

NewAge recently attained B Corp™ certification and is recognized as an organization committed to sustainability. In fact, rooftop solar panels are being considered for the company’s additional facility in Warrington, Pa., which is currently undergoing renovation. Following the remodel, the building will be used to extrude silicone and biopharmaceutical grade TPE (thermoplastic elastomer) tubing for the company’s AdvantaPure® high purity division.

Leave a Reply

You must be logged in to post a comment.