Flottweg’s Decanter and Separator centrifuges

To meet increasing production demands, the Flottweg Separation Technology’s decanter centrifuge is helping craft brewers boost yields alongside the already successful (and widely used) separator centrifuge. Separator centrifuges bring speed and efficiency to the filtration process. After fermentation is complete, the beer is pumped to the centrifuge to be clarified. The product enters the centrifuge, spreading out into many thin layers. The centrifugal force expels the solids to the edge of the bowl. The Soft Shot technology quietly ejects the separated solids which are sent down the drain or to a pump for disposal. Meanwhile, the clarified liquid flows from the disk stack to a pairing disk, where it is discharged from the centrifuge via a centripetal pump to a brite beer tank. From there it is ready for packaging.

Flottweg decanter centrifuges are used to process the hop sludge from the tank bottoms that would otherwise be dumped. Decanter centrifuges are capable of separating liquid from very heavy solids concentrations. The beer is recovered from the solids and returned to the tank while the dewatered waste is sent to a container for disposal. The process removes large amounts of solids from the waste water effluent as well as taking a considerable load off of the downstream equipment while increasing the overall yield of each fermenter. The brewers are left with a tank full of product that has very little solids left and is ready for clarification/filtration.

Festo can automate a bunch of brewery functions

Founded in 1925 in Germany, Festo has long been a partner to the brewing industry. As the world’s leading provider of pneumatic and electric automation technology, Festo offers the right solution for every challenge.

Solutions for craft breweries range from control systems for greater process consistency and improved management of ingredients to automated flow control valves and hygienic and clean design products meeting FDA standards for sanitary conditions in washdown environments. These components can be combined to ensure the brewery creates the best beers for its customers, whether those products are destined for a store shelf or sold in the taproom.

The recently available control network CPX-AP-I can help any size brewery monitor and control processes within a single unified system. This new I/O system, which is rated IP65/IP67, enables powerful I/O modules and valve terminal interfaces to be integrated.

Econocorp’s new Beer Twinseal

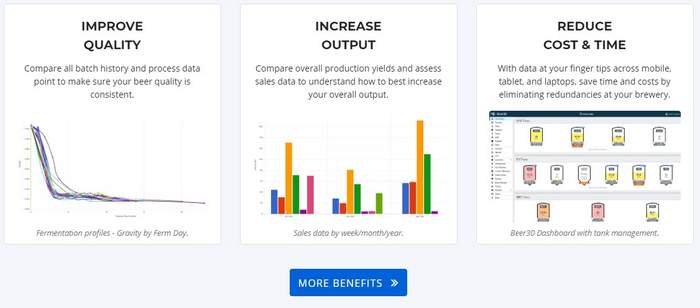

Beer30 brewery management software by the 5th Ingredient

Beer30, by The 5th Ingredient, is a brewery management software that helps breweries use their data to improve their business. Beer30 includes tools to compare over 300 data points across all batches from grain-to-glass, improve beer quality and consistency, analyze sales trends with visualizations and charts and much more. With Beer30, breweries are transforming their data into real-time cost savings.

Features include production scheduling, tank management, task assignments, raw material inventory with lot traceability, yeast tracking, process data analysis (brewing, fermenting, filtering, conditioning), packaging supplies inventory, packaging line downtime, sensory and quality, sales and distribution, barrel aging, keg tracking, batch cost analysis and real time email and text notifications. Beer30 completely integrates with Xero and QuickBooks Online.

Its CBC special entails providing customers with a 25% discount for their first three months, for anyone that signs up by the end of May 2020. With Beer30, you will have customized training sessions and have your entire brewery up and running within 10 minutes.

Providence Process Solutions’ BevOptima facility building partnership

To support this growth and provide expanded services to its client base, Providence Process Solutions announced that BevOptima has become an independently owned affiliate of Providence Process Solutions and along with BevBuilders, a Providence Process Solutions fully owned trade name, now provides integrated design, engineering, construction and facilities services to beverage processing facilities including craft beer, ciders, distilleries and spirits, health and energy drinks, sodas and seltzers and dairy products.

Whether building new, expanding or renovating, the combined solutions portfolio between BevBuilders and BevOptima can help beverage plant owners across the beverage industry refine their business process for maximum customer value, while optimizing shareholders returns at the same time.

“BevOptima supports a wide array of services that focus on the business of enhancing beverage plant owner’s profitability and customer perceived value,” noted David L. Strom, president and owner — BevOptima. “Combined, with our Lean Manufacturing, Six-Sigma, Mass Balance, Warehouse Management and plant floor to top floor data systems services, BevOptima and BevBuilders will be able to provide complete turn-key beverage plant design, build and optimization solutions.”

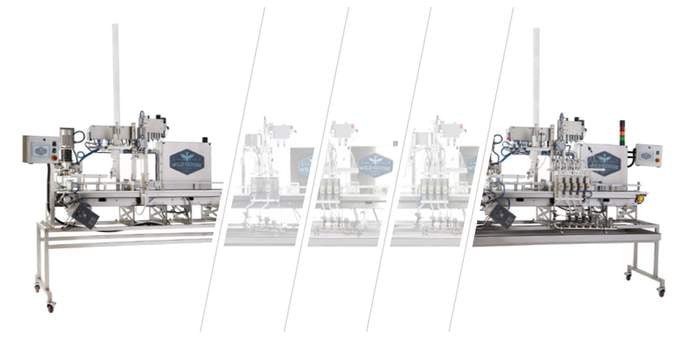

Wild Goose Filling launches new entry-level canning system

Wild Goose Filling has launched the Gosling, an entry-level automated system offering professional canning at a price point aimed towards craft producers. For craft producers looking to progress beyond manual canning methods, the Gosling takes the guesswork out of small-volume packaging. The system incorporates Wild Goose’s patented seaming and filling technology to minimize dissolved oxygen and deliver the same trusted quality and reliability as their higher speed machines. The Gosling operates at speeds up to 12 cans per minute from tank or keg and offers both single-can and continuous run modes.

The Gosling’s automated canning process is simple. Product runs can be set up via smartphone, tablet or computer. Cans are purged with CO₂ before being filled, and the system places lids automatically from a standard tube. The lidded cans are shuttled to the seamer to be sealed. Wild Goose also offers other integrated components for more control, along with additional customer incentives.

Zep on brewery handwashing

According to Bob Klinetob, regional vice president at Zep, and Adel Makdesi, senior corporate microbiologist at Zep, for soap and water to work effectively, it’s recommended that you wash your hands for at least 20 seconds. Why? Usually the skin on the hands has wrinkles. It takes time for the soap to penetrate into the wrinkles and remove viruses and bacteria that hide within. Additionally, the soap itself needs a few moments to chemically interact with the soils and germs and loosen them from the skin.

This goes hand-in-hand with proper sanitation in breweries. Our body is filled and covered with microorganisms (our normal microbiota) — some good and others bad. However, the introduction of the wrong microbe into our systems can cause major health issues and even death.

Personal hygiene isn’t so different from brewery sanitation. The implementation of proper handwashing procedures and hygiene in breweries is as important to worker safety as it is in the prevention of equipment and beer contamination. Some handwashing products that Zep recommends for breweries include its: 1. Foam Handwash — #1245 2. Sani-Slash — #AF5510 3. Wyandotte Prevent — #AF6011 4. Velvet Lotion Soap — #0958 (not for use in brewing areas).

GF Piping Systems has a new COOL-FIT polyethylene piping system

The new COOL-FIT PE Plus pre-insulated polyethylene piping system from GF Piping Systems, the next evolution of the COOL-FIT product line, offers a technological leap in process cooling. The new system provides even higher thermal efficiency, significantly reduced maintenance and operational costs and faster installation time.

COOL-FIT PE Plus includes a complete range of pre-insulated pipe, fittings, valves and hoses that efficiently convey brine, glycol, ethanol and cooled water in temperatures from 58°F to 140°F (60°C to -50°C). All surfaces are sealed and vapor tight and 100% UV-resistant. The system is 100% maintenance-free and will not corrode over time. These characteristics reduce expensive operation interruptions and maintenance.

The COOL-FIT PE Plus system has both insulation foam and an outer jacket manufactured at the factory, which eliminates traditional post-insulation work at the construction site and significantly reduces installation time. Further installation ease is accomplished by the fact that it weighs just a fraction of metal solutions, allowing roof mounting in locations often problematic for other systems.

Ekos’ stay-at-home services

Ekos partnered with five of the leading ecommerce providers to give exclusive discounts to Ekos customers who want to start selling products online. They also created content on how to drive revenue in this new environment — with curbside pickup, drive-throughs, online storefronts, local delivery, promotions and more. They’ve also compiled a list of financial resources for small businesses and breweries, specifically. Everything from emergency financial planning and instructions for applying for small business loans to grant opportunities from companies like Facebook, Amazon, Yelp and QuickBooks.

Leave a Reply

You must be logged in to post a comment.