Let’s focus on the future today. Coronavirus can cancel physical events and shut brewery doors, but it won’t stop business forever. Someday facilities will expand, new beer brands will launch and operations will need improving. To help you prep for those future days, and since there is no physical BrewEXPO America tradeshow floor to stroll this year, we put this Remote Craft Brewery Expo together for you to scroll instead. Whether you are planning on adding an entry level canning line or are in need of a simpler brewery management platform, we have the scoop on everything new and cool in the craft brewery marketplace for whenever you need it.

Weber showcases digital labels & labeling systems

If the CBC were happening right now, Weber Packaging Solutions, one of the largest label companies in the USA, would be demonstrating the abilities of its most popular wrap-around labeling system, the Pack Leader USA PL-501. This easy-to-use labeler can label up to 30-35 cans per minute and offers quick setup and easy changeover. The standard one-touch screen and label sensors make it simple to adjust for various labeling applications. And, with the manual position setting, your labels are placed accurately on the product each and every time.

Weber prints labels digitally on a wide variety of eye-catching label materials that help get products noticed in the busy modern marketplace. They will have a selection of printed samples available for comparison along with label experts that can help you get the advice you need on your next label project.

For those that need extremely short run labels for crowlers or experimental runs, Weber is showcasing the Epson C6500 high-resolution color inkjet label printer. This printer prints on a variety of label material including glossy papers and BOPP to create beautiful full-color labels easily and quickly. Other featured systems at the booth would have been:

- Markoprint X Jet Ink Jet — adding date code info to the craft beer labels

- BestCode Continuous Inkjet system — for adding date codes to cans or bottles on your line

- Custom Printed Labels — get free sample label packages!

For more information on Weber Packaging Solutions:

- phone 1.800.843.4242;

- email [email protected];

- web www.weberpackaging.com.

ZIEMANN HOLVRIEKA’s turnkey brewhouses

Enthusiastic brewers and their high-quality beers characterize countless ZIEMANN HOLVRIEKA breweries worldwide. These are some of the main reasons for the company’s successful turnkey projects:

- Flexibility: Off-the-shelf solutions limit the flexibility and finally the creativity of the brewer. Together ZIEMANN HOLVRIEKA identifies the brewery’s goals and develop solutions that fit. In this regard, it also takes into account the brand mix, individual layouts, process flow, budgetary pricing and many other aspects.

- Stay optimized: ZIEMANN HOLVRIEKA remains your partner even after implementation of your project. Turnkey does not mean that the company leaves you alone when something remains unclear.

- One-stop turnkey provider: Service covers engineering, project management, hard- and software planning as well as the installation of all equipment. ZIEMANN HOLVRIEKA produces all the brewing equipment, from mashing-in vessels up to bright beer tanks. Furthermore, it ensures the seamless integration of sub-suppliers and take care of all interfaces.

ZIEMANN HOLVRIEKA is the global market leader for stainless steel tanks for breweries and complete cold block installations. The company offers:

- Consultancy: The first step when planning a tank installation is to consider the best arrangement for the specific project. This is crucial in terms of costs, ergonomics and future expansions.

- Highest quality: ZIEMANN HOLVRIEKA’s inner surfaces can achieve a guaranteed roughness of less than 0.4 μm. This contributes significantly to the effectiveness of cleaning and biological safety.

- Flexibility: ZIEMANN HOLVRIEKA offers a wide range of design variants, mounting options and smart detailed solutions to ensure complete flexibility of the tank farm.

Aquatherm is revolutionizing the way craft breweries are piped

As the innovator and pioneer of polypropylene piping systems in North America, Aquatherm has been widely embraced by brewers throughout the United States and Canada. Aquatherm’s polypropylene piping systems, which are connected by heat fusion, are virtually leak-free and ideal for glycol lines — that was its initial introduction to brewing applications a decade ago.

But Aquatherm pipe also can be used for domestic water, compressed air, heating and cooling and CO2 lines. Aquatherm Green Pipe, which is NSF/ANSI 51-listed for food-grade applications, can be used for domestic water or even to transport the beer itself. As a chemically inert material, polypropylene will not leach into or affect the taste or smell of the liquids it is transporting.

In many craft brewery applications, polypropylene represents a significant upgrade from metal pipe such as copper or steel. Polypropylene does not react with water, glycol or other products and ingredients found in breweries. It will never scale or corrode, and it does not become brittle over time or fail when exposed to extreme temperatures.

They won’t be seeing you at CBC in San Antonio this year (curse you, COVID-19!) but you can, from the safety of your own home, check out aquatherm.com for more information. And if you’d like to hear from some brewers about why they love Aquatherm, well, here you go

BrewSavor hoses and tubing by New Age Industries

BrewSavor recently relaunched its website, www.brewsavor.com. The original site went live in March 2019 with the introduction of the BrewSavor product line, which features tubing and reinforced hose for brewing and beverage dispensing.

The redesign though presents a well-organized look at the company’s products engineered for fluid flow in craft and commercial breweries, beverage dispensing applications and home brewing operations. Viewers can also explore products based on cold or hot brewing processes or by tubing or hose usage such as brew hose, beverage line or gas transfer.

Products on the site include crush resistant and kink resistant brewery hose assemblies and a selection of tubing and reinforced hose for fluid transfer and gas lines. Styles include:

- Phthalate free,

- Antimicrobial,

- NSF listed, and

- Tubing with barrier properties to limit oxygen and CO2 ingress and egress.

GR-X Manufacturing has a new ECO can depalletizer

GR-X Manufacturing offers a variety of bottle and can depalletizing systems — ranging from entry-level manual half-height units up to full-height automated high speed systems.

GR-X is excited to introduce its new ECO can depalletizer shown with a compact mini side-grip lowerator. The ECO can depalletizer is designed to offer an economical and automated solution for unloading full-height pallets of empty aluminum cans. The mini side-grip lowerator gently grips cans and lowers them from discharge height to line level. It features tool-less multi-point adjustability to handle a large range of can sizes for quick and easy changeovers, thereby eliminating the need for multiple rod-chutes or bulky change out parts.

Full-Height Automatic ECO Can Depalletizer (Accepts 44” x 56” pallets)

- Heavy-duty tubular carbon steel frame construction

- Industrial powder-coated finish on frame

- Clear lexan door for easy view of pallet status

- Motorized sweep assembly frame

- Automatic slip-sheet removal system

- User friendly HMI touch screen controls

Mini Side-Grip Lowerator (Lowers cans from discharge height to line level)

- Tool-less multi-point adjustability to handle a large range of can sizes

- Quick and easy changeovers

- Reduced footprint to save valuable floor space

- Optional ionized air-rinse system

- Optional can stamped date coder

GR-X is easy to work with and takes great pride in the equipment they manufacture — it’s company philosophy is “Equipment built well — sales made simple.” View its full line of depalletizing machinery at grxmfg.com/depalletizers.

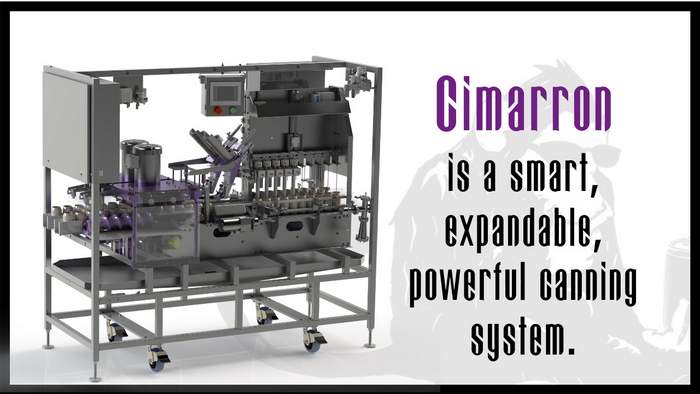

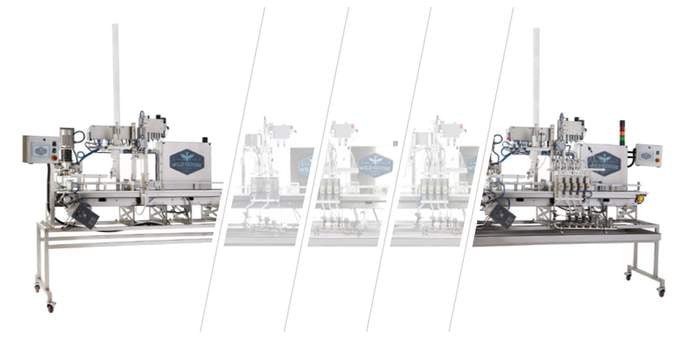

Twin Monkeys has a new, expandable canning system (1-10 fill heads)

Twin Monkeys Beverage Systems announced the release of its new expandable from 1-10 fill head system, The Cimarron. The Cimarron is Twin Monkeys’ most advanced canning system yet. The Cimarron allows customers to custom configure the machine that works best for them. It also allows customers to plan for growth without the need to purchase a new system when their capacity increases.

Josh Van Riper, Twin Monkey Beverage Systems, CEO said, “We wanted to design a machine that made sense for the craft beverage industry. Our machine can grow with the customer, whether the customer wants more throughput or wants to run new can sizes. It was purpose desgined so that all the features and options help ensure that the beverage quality is maintained through the canning process.”

The Cimarron has the capability to run slim, sleek and standard cans. Change out between diameters is designed to be quick allowing customers to make the most of their time. It has the ability to package beer, wine, soda, kombucha, cannabis infused beverages, CBD beverages, ready-to-drink mixed drinks, water, juice and coffee or tea. The Cimarron is built to allow customers to configure their system:

- Single or dual lane configuration! (1-10 Fill Heads) No increase in footprint for dual lane configuration.

- Weigh, reject and automated-fill adjust feature

- Rinse water reuse: The water used to pre-rinse your cans can be collected and re-used to rinse again post-seam. Eco friendly and economical!

- Automated fobber to add the perfect foam to each can for advanced oxygen reduction

- Multiple infeed options

- Fully integrated with liquid nitrogen doser. Can independently run each lane’s doser!

- Servo fill head control for precise control over fill conditions

Weber Scientific updates sanitation monitoring technology from Hygiena and Kikkoman

Weber Scientific distributes laboratory supplies and equipment throughout North America and is focused on the specialized testing needs of the brewing industry.

Now, new EnSURE Touch responsive touchscreen design puts all the functionality and features of Hygiena’s ATP Monitoring Systems at your fingertips. Only the New LumiTester Smart, Kikkoman’s new A3 Sanitation System, distributed by Weber Scientific, detects ATP+ADP+AMP with one swab to give you the whole picture with its patented A3 Technology, proven to detect residues others miss.

Weber is your source for ASBC method microscopic yeast cell counting supplies. The company has hemocytomers with standard or bright lines, cover slips, viability stain and a range of microscopes to fit your needs.

Weber also offers all-inclusive microbiological testing supplies, including culture media for the brewing industry, and wide selection of general dehydrated media including Univeral Beer Agar, WL Differential Agar, Barney Miller Agar and Weber Scientific brand HLP, LCSM, LMDA and LWYM.

Weber Scientific is the exclusive distributor of the Farber Pham Diastaticus Medium, a novel media for the detection and enrichment of Saccharomyces cerevisiae var. diastaticus, and they are are North America’s only stocking distributor of Doehler NBB Prepared Culture Media for Beer, which also offers a full range of Membrane filtration supplies specially designed for microbiological testing, products including prepared media ampoules, sterile membrane filters and ready-to-use sterile disposable filtering funnels. The Gaspak EZ Anaerobic Container System from BD is an economical option for the cultivation of anaerobic bacteria.

Ardagh Group’s new bottle designs

BuyOurBottles.com (BOB) is brought to you by Ardagh, one of the leading glass container manufacturers in the United States. By the pallet or truckload, BOB and Ardagh have you covered with the ideal shapes and styles you need.

At the show, brewers would have been able to explore its new stock bottle designs in the ideal shapes and styles ranging in sizes from 12 to 64 oz. But hey, don’t worry — you still can online. On BuyOurBottles.com, you’ll find a selection of attractive beer bottle styles with instant pricing and shipping quotes, and checkout is a breeze using your credit card or PayPal account. Or, you can purchase a full range of bottles from Ardagh directly at 636-299-5495 (Central), 856-455-2137 (East), 707-200-9350 (West) or via [email protected].

CODO Design’s handy Rebranded book and workbook

CODO Design will be presenting a seminar at the 2020 Craft Brewers Conference called “Using Science to See What Packaging Works and How Your Brewery Can Sell More Beer.” This will be part of the Brewers Association’s virtual CBC.

Beyond this, CODO will be promoting its new book, Craft Beer, Rebranded. As of 2020, there are over 8,000 craft breweries in the United States, with thousands more slated to open over the next few years. The market has shifted and increased competition from small outfits and Big Craft alike all serving a more educated and fickle consumer base. Add to that an ever-changing sales and regulatory environment, and breweries around the country are feeling the need to update their branding not just to clean up their presentation, but to stay relevant and competitive.

Craft Beer, Rebranded (and its companion workbook) are a step-by-step guide to help you map out a successful strategy for rebranding your brewery. Based on CODO Design’s decade of brewery branding experience, this book will help you weigh your brand equity, develop your brand strategy and breathe new life into your brand. Whether your brewery is three years old or 30, Craft Beer, Rebranded is your guide to attracting new audiences, selling more beer and positioning your brand for the long haul.

SPECS:

- 180 page paperback book (full color)

- 60 page companion workbook (one color)

- One #2 pencil

Gusmer Enterprises

Gusmer Enterprises is offering a full range of products to help serve the brewing industry. This year, the company has several new vendors with a wide variety of products.

- mbt Brautechnik Brewhouses — Proven to be a high quality solution provider for the small-to-mid sized craft brewers, specializing in a full range of brewhouses.

- Christian Gresser Tanks — Offering the world’s finest brewery tanks including cylindroconical and open top fermentation vessels.

- Christian Gresser Yeast Propagation — The perfect solution for your yeast management needs, with patented, proven yeast propagation technology.

- Chr. Hansen Brewing Yeast — Now offering SmartBev NEER, designed for low and non-alcoholic beer and SmartBev DIBS CA-1, a pure culture of Saccharomyces cerevisiae to be used specifically for ale type beers.

- Chr. Hansen Sour Beer Cultures — SmartBev Harvest LB-1 is the first pure Lactobacillus plantarum culture selected specifically for sour beer production.

- DENWEL — Designs and manufactures a wide range of specialized equipment and provides engineering solutions dedicated to help brewers optimize their processes. Products includes Inline Gas Injection, Blending & Dosing, Water Deaeration, Flash Pasteurization, and CIP.

- Malek Brautech Keg Washing & Filling Equipment — Solutions for breweries of all sizes — from simple, small-scale 15 keg/hr washers to complete, turn-key keg lines with external and internal washing, filling and palletizing capability and capacity up to 1000 kegs/hr.

- PureMalt Crafted — A diverse range of traditionally brewed malt concentrates.

For a complete offering of products, download the company’s new brewing catalog here or for more information contact your local Gusmer sales rep or visit it online at www.gusmerbeer.com

LJ Star’s MetaPlex Sanitary Window

L.J. Star, Inc. (www.ljstar.com), a leading provider of process observation equipment, was presented with a LEAP award for design innovation by Design World Magazine. Describing the product as “elegant and brilliant,” a panel of 18 engineering experts awarded the MetaPlex Sanitary Window by L.J. Star first place out of more than a 100 entries.

Specifically designed for applications where glass is not the desired choice, the MetaPlex sanitary windows is used in place of a glass sight window on tanks and vessels during chemical, beverage and other process applications. L.J. Star found a solution for replacing glass, which is not desired in many process applications, with a highly engineered polymer that could withstand the extremely high temperatures and pressures associated with many process industries, yet still retain the visual clarity of glass.

A MetaPlex sanitary window is formed by injecting the polymer into a precisely formed sanitary metal ring, which eliminates the dangerous weak point of the thin section that appears on competitors’ all-plastic windows.

The patent-pending MetaPlex windows provide a level of safety and useful service life well beyond that provided by conventional plastic sight windows. They are the only polymer sanitary window to withstand temperatures up to 134°C, operating temperatures to 100°C and operating pressures up to 150 psig. They also provide good chemical resistance to acids, alkalis (caustics) and alcohols. While other plastic sight glasses are meant for short term use during validation, process development and engineering applications, the MetaPlex optical grade polymer sanitary windows are durable enough for use even in CIP and SIP cycles, eliminating costly down time.

Some of the unique features of the MetaPlex sanitary windows include:

- The only optical grade polymer sanitary window on the market that offers a stainless-steel ring

- Extremely strong and chemically resistant to acids, alkalis (caustics) and alcohol

- The only polymer sanitary window that can withstand:

- Temperatures up to 134°C

- Operating temperatures to 100°C and

- Operating pressures up to 150 psig

- Glass-like transparency with enhanced safety

- Stronger than competitor units that are all-acrylic or polycarbonate

- The only non-glass sanitary window durable enough for use in CIP and SIP cycles

LJ Star also makes these awesome inline sight glass lights.

Head to page two for more cool stuff, including centrifuges, brewery management software, facility construction services and much more.

Leave a Reply

You must be logged in to post a comment.