The Craft Brewers Conference and BrewExpo America is next week, May 7-10, in Nashville, Tenn. Are you ready? No, you’re not. How do I know? Because you haven’t yet skimmed these handy CBC 2023 previews from Craft Brewing Business! We reached out to all of the exhibitors to tell us what they’ll be showing off this year. Here is what they had to say.

Wild Goose Filling | Booth 1909

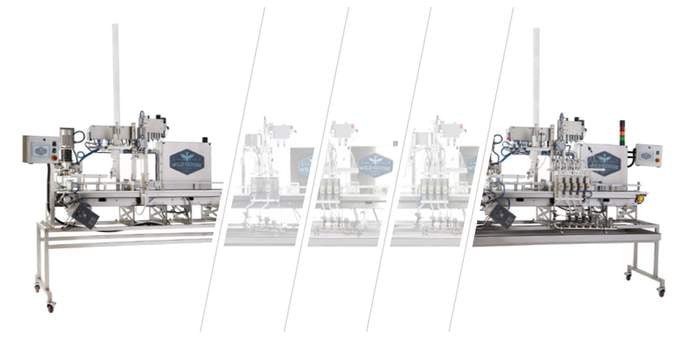

At CBC 2023, Wild Goose Filling will launch the new generation of its best-selling Gosling canning system. Gosling 2.0 incorporates an all-new user interface with an embedded high-resolution touchscreen display to give the operator a fast, consistent operating experience at the touch of a button. With the addition of an intuitive plug-and-play panel and universal can entrance, Gosling 2.0 also makes the setup process for every canning run quick and simple.

Gosling 2.0’s enhanced stainless-steel safety enclosure offers ergonomic operation and cleaning with long-term durability. The system is CE-certified and accommodates multiple can sizes, with the option to add liquid nitrogen dosing for still beverages. New Gosling 2.0 add-ons are also available for extra automation.

Designed to maintain quality for small-volume packaging, the Gosling offers speeds up to 12 cans per minute based on 12-ounce cans. The Gosling incorporates Wild Goose’s patented filling and seaming technology to deliver the same consistency as higher speed Wild Goose canning systems. The system gives breweries the ability to package a variety of beverages on a smaller, more affordable scale than traditional automatic canning systems while offering better protection against dissolved oxygen compared to manual fill-and-seal appliances.

For more canning insight from Wild Goose, check out this recent article on how to prevent dissolved oxygen in canned beer.

Pneumatic Scale Angelus | Booth 925

PSA uses the innovation of our high-speed lines in our slower-speed, lower production units for craft beverage producers. Our inline canning units, like the CB50F and CB100F, are open-air systems with proprietary flowmeter technology and a gas-flush system for oxygen level control and are suited for small batch production with frequent changeovers and run at speeds of 15 to 100 CPM (cans per minute).

In addition, the CB50C and CB100C use counter-pressure filling technology to meet the increased demand for higher-carb beers, sparkling wines, and seltzers.

The CB100C is a rotary counter pressure system using a 12-head rotary filling turret coupled with a dual seamer to increase throughput. The gentle filling action diminishes agitation, keeping carbonation levels up to the brewer’s standards.

For advice on buying a canning line (like where to start and questions to ask), check out this recent article from PSA.

INX International Ink Co. | Booth 363

As the leading metal decorating color standard, brand owners, beverage marketers and can makers have learned that INX International’s Color Perfection program is the best way to successively produce a new can product for the marketplace.

The extremely efficient design-to-market process opens the door to significant cost savings, brand consistency, color accuracy and more advantages. This program from the market leader in metal decorating inks and color management technologies includes the INX 2-Piece Metal Color Catalog and digital color library; it also encompasses digital printing and an educational platform with free courses available from INX University.

“The INX Color Catalog continues to be instrumental in serving the beautiful illustrations and designs on each of our cans, and appealing to customers with exciting visual appeal on the shelf,” remarked Jameson Campbell, creative leader of Great Lake’s design team. “It helps us best match the color, capacity and transparency of inks to maximize the boldness of each can’s final appearance. INX has helped us deliver each beer’s unique story and flavor promise to our customers, reach new drinkers, and build even stronger brands.”

Entries for this year’s contest must be postmarked by May 31 and the winner will be announced in mid-June.

Axon | ProMach | Booth 433

Axon, a ProMach product brand, will showcase the recently released HE-500 steam shrink tunnel, which offers craft brewers a patented design for superior performance. The HE-500 steam shrink tunnel offers a reliable and energy-efficient system that will help their products stand out on the shelf. With an integrated low-pressure steam generator, the HE-500 delivers superior shrink performance; and with minimal condensation in the tunnel, the finished product is markedly drier upon exit when compared to traditional steam tunnels. The HE-500 also offers operator-friendly controls, and the toolless changeover process is simple, intuitive and repeatable.

In addition to the HE-500, Axon will also be showcasing their EZ-150SL sleever, a value-priced, small footprint, mandrel-style shrink sleeve applicator designed to run up to 150 containers per minute. Developed with ready-to-drink beverage cans in mind, the EZ-150SL uses servo motion control to deliver consistent performance, making it an ideal solution for craft brewers looking to increase production efficiency.

“We understand the unique challenges that craft brewers face, and our products are designed to help them improve their manufacturing productivity and the shelf appeal of their end product,” said Bob Williams, Vice President and General Manager at Axon. “We are excited to showcase our latest technologies at the Craft Brewers Conference and discuss how we can help attendees improve output at a lower cost, delivering superior value to more customers.”

Roberts PolyPro | Booth 433

Meanwhile, Roberts PolyPro, another ProMach product brand, is showcasing its LDPE can rings, Grip-Pak, which are now biodegradable certified, following independent testing conducted by a leading agency. The testing was conducted in controlled laboratory conditions that mimic an urban landfill environment for biodegradation of plastic products. Over the course of 28 weeks, the scientific test revealed that Grip-Pak carriers biodegraded in their entirety (100%) without the presence of false-positives or false-negatives.

“We are committed to reducing the environmental impact of our products, and Grip-Pak’s biodegradable certification is an important step forward in that effort,” said Roy Tetreault, Vice President and General Manager of Roberts PolyPro. “We have extensively tested the performance of the biodegradable Grip-Pak carriers, including stressors encountered during transportation and handling, and we are confident that they offer the same durable and effective market-tested performance our customers have come to expect.”

In addition to the biodegradable LDPE can handles, Roberts PolyPro will also be showcasing their 100% recyclable HDPE can carriers, Craft-Pak, and inline applicators at Craft Brewers Conference.

American Canning | Booth 1700

Increased shelf-stability from the most sustainable can in the world. Sounds too good to be true, right? aTULC cans, manufactured by American Canning, offer just that. The technology utilizes a dual-sided, pre-coated aluminum sheet that results in a more robust liner for increased shelf-stability. Subsequently, the process is waterless – making their environmental impact significantly lower than that traditionally seen in the market.

American Canning is officially producing custom printed cans as well as multiple colored stock brite aTULC cans.

Also, American Canning is introducing the AT-6 to transform your packaging production. This atmospheric filler/seamer stays true to the high-quality, lightweight, simple design philosophy of American Canning at new speeds.

Weber Packaging Solutions | Booth 1931

Weber Packaging Solutions, a family-owned label company that has been helping companies look their best for over 90 years, will be exhibiting their digital label printing and automatic labeling capabilities at the Craft Brewers Conference show. Visit Booth 1931 to get free samples of labels specially printed for the craft beer industry.

Weber will be demonstrating can labeling with its most popular wrap-around labeling system, the Pack Leader USA PL-501. This easy-to-use labeler can label up to 30-35 cans per minute and offers quick set-up and easy changeover. The standard one-touch screen and label sensors make it simple to adjust for various labeling applications. And, with the manual position setting, your labels are placed accurately on the product, each and every time.

Weber prints labels digitally on a wide variety of eye-catching label materials that help get products noticed in the busy modern marketplace. They will have a selection of printed samples available for comparison along with label experts that can help you get the advice you need on your next label project.

Iron Heart Canning | Booth 2152

Iron Heart Canning is a premiere mobile canner. Its mission is to provide unrivaled, dependable service, thus eliminating the need for our customers to purchase their own in-house systems. Strong partnerships, integrity, and hard work are at the core of its business, and its offerings are designed to make it as easy as possible for breweries and other beverage producers of all sizes to join the can market.

THIELMANN | Booth 2658

THIELMANN will be showcasing its high-grade stainless steel solutions for the beverage industry. Its containers include all standard US beverage kegs, and aseptic IBCs with 264 gal capacity for fermentation, carbonation, and yeast propagation, as well as cost-effective Corny kegs, with manual access via the oval handhole. All can be branded up, and short lead times can be catered for with kegs and aseptic containers.

THIELMANN takes pride in its kegs, producing containers of the highest quality materials, delivering unrivaled hygiene standards, protection for the beer they contain from UV light, pollution particles, and corrosion – and they are built to last a lifetime.

As part of its commitment to quality kegs, THIELMANN is a founding member of the Steel Keg Association. Along with other players in the keg supply chain, THIELMANN works to raise awareness of the environmental and financial benefits of steel kegs. Whether you’re a brewer or any other industry professional, speak to a THIELMANN rep about what THIELMANN quality can bring to your operation. Or, if you have a bespoke project in mind, their team will be on hand to discuss the proposal.

Saturn Packaging | Booth 2737

Saturn Packaging specializes in manufacturing end of line packaging solutions for the canning and bottling industry. Its conveyor systems, accumulation systems, air blower tunnels, shrink bundlers, tray packers and sustainable compostable ECOCAPCLIP can carriers are tailored for all sizes of breweries and distilleries. Saturn also integrates other machinery such as rotary fillers and seamers.

The EcoCapClip sustainable can carriers are made with 100% recycled cardboard and compostable materials. The EcoCapClip can carriers are the strongest in the market due to its patented design, rigidity and thickness. It is a freezer board carton that is tested against humid and wet areas. Its customizable feature makes your product unique and stand out on the shelves. Barcode integration is also possible.

Apply EcoCapClips with affordable and reliable automated and manual applicators made in Canada. 4pack, 6pack and 24pack available. All our EcoCapClip related products are made in Canada.

Leave a Reply

You must be logged in to post a comment.