Despite late planting and a cool spring, the malting barley harvest is underway and initial quality and yield reports are favorable.

“Growers are pressing hard to get the crop out of the field between weather events, but early harvest results also reflect test weights in the 49 to 53 lbs per bushel range,” reported Wade Malchow, barley program manager at Molson Coors Beverage Co. Malchow also serves as the chair of the Agriculture Policy committee for the American Malting Barley Association (AMBA).

Late planting, however, can lead to a later and often more prolonged dry down and harvest period.

“In recent years, the industry has seen an increase in barley harvested at higher moisture levels, especially in the more humid Midwest growing region. The lateness of this season could exacerbate that issue,” shared Scott Heisel, president of AMBA.

AMBA is an agricultural trade association that represents end-users of malting barley whose mission is focused on ensuring a sustainable and high-quality supply of domestic malting barley for its membership.

Drying of malting barley must be done with great care as the malting process requires barley with a high percentage of vigorously germinating kernels to produce the quality of malt needed for the brewing, distilling, and food industries.

Heisel commented, “Growers have a lot invested in their crop, and a little extra care at harvest time will ensure they meet malting specifications.”

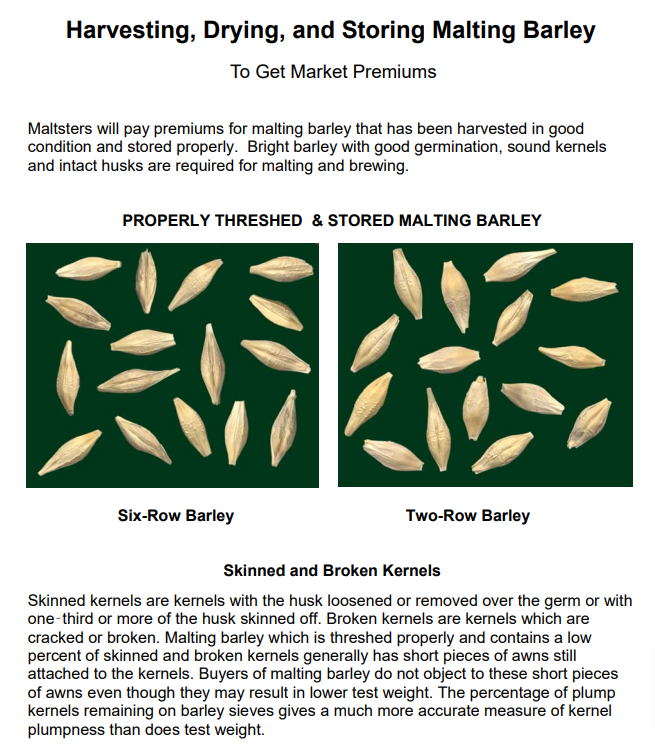

AMBA partnered with North Dakota State University and the Institute for Barley and Malt Sciences on the publication: Harvesting, Drying, and Storing Malting Barley, which outlines best practices for post-harvest handling of malting barley to ensure quality. As outlined in the publication, malting barley should be dried without added heat, but if heating must be used, the air should be no warmer than 100°F. Consulting with your barley purchaser on preferred post-harvest handling procedures is also recommended.

Leave a Reply

You must be logged in to post a comment.