Sovos ShipCompliant offers a system for electronic brand registrations for beer, wine and spirits. We posted some data from its Product Registration Online (PRO) system earlier today. ShipCompliant’s solutions reduce risk, lessen the burden of compliance, accelerate bringing products to market, and enable revenue growth. The company was set to host the Beverage Alcohol Summit in March, covering a ton of ground at the intersection of distribution, compliance and automation. Then coronavirus happened.

Pre-coronavirus, I reached out with some questions, and Alex Koral, J.D., Senior Regulatory Counsel with Sovos ShipCompliant, sent back some answers. Post-coronavirus, I forgot about everything that ever happened to me. Now that quasi-normal life is on the comeback, and with previously taproom-focused breweries looking to ramp up off-premise sales channels, my brain finally remembered I had this Q&A. Might come in handy. Here ya go!

CBB: Breweries face some time-consuming manual reporting and compliance tasks — which ones are the most overlooked?

Koral: The beverage alcohol industry is among the most heavily regulated in the United States. To stay compliant with a myriad of local, state and federal requirements, breweries are required to keep and maintain accurate records of specific sales and distribution data. As a result, regulatory reporting becomes a tedious fact of life that every brewery must manage.

For example, for every order they fulfill, breweries have to know exact delivery dates, addresses and complete content details, which they must report regularly to relevant state agencies. But each state has its own data requirements, which can vary greatly in their complexity, adding to the hefty amount of time it takes to manage these processes.

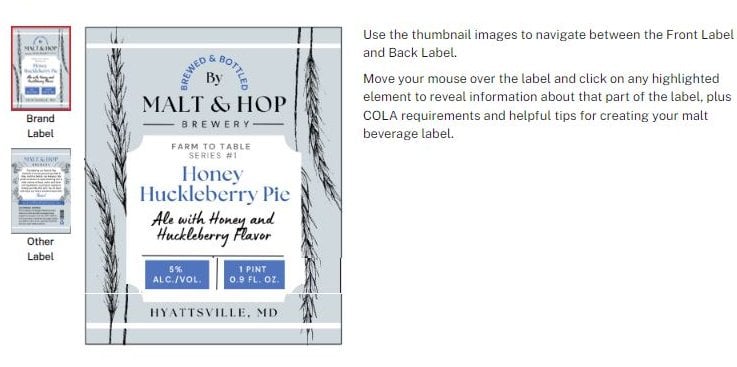

One area that is often overlooked is brand/label registrations. State-specific rules and registration requirements must be followed to the letter. When breweries fail to properly register their brands/labels with the state, they cannot legally sell their product in the state and can greatly delay their time to market. While registrations aren’t reports per se, they do represent an added barrier for breweries looking to expand their market.

CBB: What are some of the nuances in terms of details, timing, etc.?

Koral: Details vary greatly across states, so a one-size-fits-all mindset cannot work. Breweries have to be state-specific in their approach.

For example, many states spell out specific ways that case configurations should be reported, e.g., 12×12 oz. or 6×12 oz. must be reported separately. If a brewery’s products don’t conform to a state-specific configuration, sales managers have to manually do the math to report in a format the state will accept. These reports generally need to be filed monthly, creating a near-constant churn of reporting that can leave teams scrambling at the last minute.

Yet failure to file accurate reports in a timely manner is a reason a state would consider not renewing a brewery’s license, potentially leading to a total shutdown of operations.

CBB: Where does automation come into play? Give me a few examples of the various process improvements that can be gained.

Koral: By automating sales and reporting, breweries can take concrete steps to ensure reports are accurate and available well ahead of reporting deadlines. Whereas these reports used to require lots of manual calculations and writing everything out by hand, modern solutions like those from Sovos ShipCompliant automatically process and populate each state’s specific forms in the blink of an eye.

Similarly, with brand/label registrations, an automated service can alert breweries when they need to provide additional supporting documents, such as brand authorization forms or laboratory analyses, depending on state requirements.

And there are plenty of other regulatory hurdles that automation can alleviate. For instance, brewers must ensure they always have active licenses allowing them to sell to wholesalers in their destination states. If a brewery fails to renew their license on time, they can lose that privilege. So having timely alerts that their license is going to expire soon, along with notices on what is required to renew the license, can save a brewery from a lot of grief.

Similarly, having a system that recognizes when a state has approved a brand/label registration can inform the brewery’s other teams that a product is ready to sell and distribute in that state. Again, these are solutions provided by Sovos ShipCompliant.

CBB: I assume this shift to automation also improves relations with wholesalers?

Good compliance begets good sales. By managing compliance needs, breweries can avoid future issues with state regulators and expand their sales offerings quicker.

Wholesaler consolidation means that there are fewer options out there for small breweries to work with. Demonstrating proactivity when it comes to compliance shows wholesalers and distributors that a brewery is ready for expansion. On the flip slide, when breweries fail to meet compliance requirements — by selling without the appropriate license, marketing products that have not been registered with the state, missing required reports and the like — they are risking a serious downstream impact on sales.

Automation won’t remove these compliance barriers, but it does make them easier to manage. Reducing the time and effort for complying with any one state gives breweries the scope to add more markets and products to their current sales offering.

The Sovos ShipCompliant Product Registration Online (PRO) system is available in more than 20% of the county, including Arkansas, Colorado, Illinois, Kentucky, Louisiana, Minnesota, New Mexico, New York, Oklahoma, South Carolina, and South Dakota.

Leave a Reply

You must be logged in to post a comment.