Denwel creates specialized equipment and engineering solutions to help optimize production processes in a variety of industries. Based in the Czech Republic, the company engineers, manufactures and installs a wide range of specialized brewing equipment — water deaeration, blending, carbonation and nitrogenation, dosing, CIP and flash pasteurization systems. The company integrates all of this equipment into highly efficient and reliable cold block solutions. In fact, we just covered Denwel’s wort aeration and wort oxygenation equipment in our Craft Brewhouse Showcase 2021.

In North America, Gusmer supplies Denwel brewing equipment. Gusmer also provides brewing expertise on everything from fermentation to filtration to processing aids and beyond, selling everything from lab equipment to entire brewhouses, often as a distributor. This week Gusmer released an excellent webinar on Denwel inline carbonation/nitrogenation equipment, which you can watch above. The insights shared range from the principles of inline injection to the ideal setups for the equipment to the benefits of inline carbonation and nitrogenation vs. in-tank.

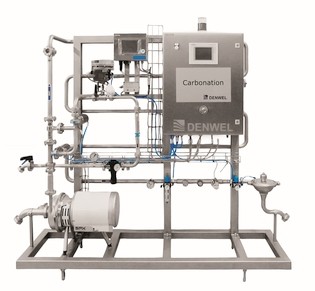

Gusmer offers a variety of inline carbonation/nitrogenation models from Denwel — its Mobile Manual Unit (CO2 is injected into the beverage through the Denwel Injector, which splits the gas into micro bubbles), Semi-Automatic Unit (designed for continuous carbonation of beverages, where a precise CO2 ratio injection maintains carbonation at desired concentration) and the Automatic Unit (designed for continuous carbonation of beverages, PLC controlled and has automatic modes for continuous carbonation and CIP).

How do these units help a craft brewery?

“How does inline work?” asks Matt Pino, technical sales representative for Gusmer in the Northeast, in the video above. “Essentially. the gas is injected right into the beverage … The gas is split and creates these little micro bubbles that are actually going to provide the direct saturation of the gas right into the liquid its going through. In this case, generally specifically beer. You’re going to be able to carbonate and add nitrogen, whichever you’re looking for.

“And the real big benefits are continuous process. When we say, what does this achieve? A continuous, simple process. Fits really nicely after filtration and centrifusion. And there’s no mixing. You don’t have to recirculate. There’s no stones. There’s no candles. It’s direct, easy, painless.”

Learn more above.

Leave a Reply

You must be logged in to post a comment.