Nothing looks cooler than leisurely carrying a six-pack of beer into a party. Roberts PolyPro provides a key comp/onent in this type of beer transport — can handles for two-, four- and six-pack beer configurations. For 25 years, Roberts PolyPro has been refining the injection molded experience in products that range from carton handles to hangers to beer holders. The company’s can products in particular offer a nice balance of eco allure, easy application and product security.

“Our handles are distinctive,” said Roy Tetreault, vice president and general manager of Roberts PolyPro, which is a ProMach brand (a family of brands that operate across the entire packaging spectrum). “They meet the brewers’ need for secure control of the pack and the consumers’ need for ease of use. We strive to reduce the amount of plastic in our handles to make them more sustainable, and all of our handles are recyclable. We also offer a single source for application technology, and our machines are built for long years of service.”

The big hook here for me is the 100 percent recyclable HDPE injection-molded can handles. Ok, it’s plastic, but the company promotes using less plastic than competitive style handles. The HDPE No. 2 handles are available in any PMS color. Tabs that push in to hold and then lift to remove give the handles their distinctive appearance. On outings, the handles can be reapplied to cans for convenient carrying home to refrigerators or to recycling bins for empties.

“Our can handles offer the additional advantages of being attractive,” said Tetreault. “Brewers can order the handles in custom colors to match their can design. The handles help products stand out on the retail shelf. The Roberts PolyPro handles also promote air circulation on the top of the can. So, no molds and no ick factor for consumers drinking out of the can. These handles are lighter than most. Consuming lower amounts of plastic not only makes them more sustainable, but also more cost-effective. Roberts PolyPro recently launched a second-generation design that is even more distinctive. These handles can be personalized with brewery logos and other graphics.”

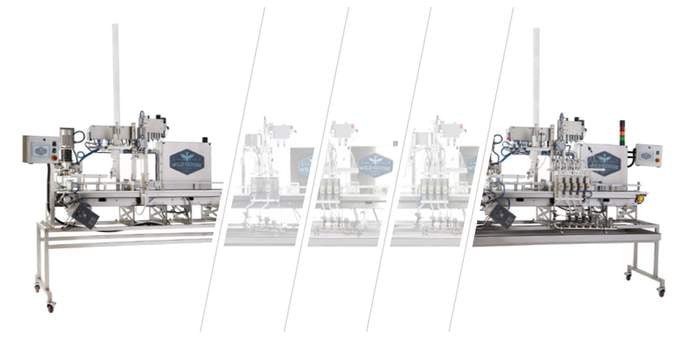

Roberts PolyPro can handles are ideal for shorter production runs and seasonals. The handles can be applied by hand, but Roberts PolyPro also offers four applicators — a manual applicator, semi-automatic (MCA-10), Automatic 240 can per minute in tray applicator (pictured below) and an automatic tray loader with an applicator combined. These robotic machines can be configured to apply handles at 30 and 55 trays per minute. That’s a lot of cans.

“We see cans as the preferred packaging for craft brewed products because of longer shelf life and the overall benefits to the quality of the beer,” explained Tetreault. “We forecast a growth in taproom canning because the margins are so good. This will appeal to those craft businesses that are focusing on taproom sales rather than growing through distribution.”

Roberts PolyPro has worked with a diverse group of beer makers — BVM Brewery in Quebec, Baxter Brewing Co. in Maine and Wormtown Brewery in Massachusetts — refining the design of its handles and applicators. You can enjoy a joke reel posted on Wormtown Brewery’s Facebook page, showing Warehouse Manager Casey O’Donnell trying to hand customers a four-pack of the Wormtown’s top-selling Be Hoppy IPA only to have the cans fly out of the flimsy four-pack rings. The 60-second video encapsulated Wormtown Brewery’s months-long journey finding the Roberts PolyPro can handles showcased.

“Brewmaster Ben Roesch ordered a trial batch of handles,” said Tetreault. “He wanted to solve the rings problem. When the handles arrived, he set aside an accumulation table where two of the company’s packaging team would manually create 4,500 four-packs in 750 cases during a trial run. These team members spent about a half hour getting the feel of the handles, looking for the best process. After 750 cases of four packs were completed, team members found that they cut two hours off the anticipated handle application time.”

Wormtown Brewing now uses the handles on its new automated canning line with a Roberts PolyPro applicator. Both Roberts PolyPro can handles and that MCA10 can handle applicahtor will be on full display at theCraft Brewers Conference and BrewExpo America in Denver from April 8-11 at booth No. 8129. Stop by to learn more about these cool can handles.

“We listen carefully to the business situation of our customers and propose solutions that meet their needs,” said Tetreault. “There are many creative ways to do that. Craft brewers should give us a call and lay out their general volume requirements. Management will consider making them a creative offer fitting their needs.”

Leave a Reply

You must be logged in to post a comment.