The Craft Brewers Conference and BrewEXPO America is the biggest event of the year for the craft beer industry. There’s a lot to see and do, and to help you navigate it all, we present this #CBC2019 preview series. Stay tuned over the next few weeks as we relay the cool products and services making their debut around the expo floor this year. If you have an announcement to share, let us know at [email protected]. The 2019 BrewEXPO takes place at the Denver Convention Center from April 8 to 11.

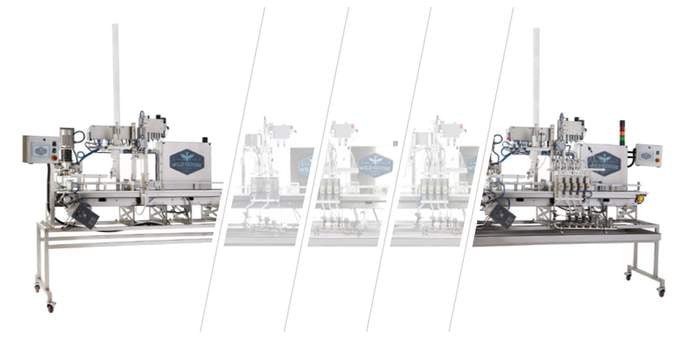

Multi-Conveyor | booth 22059

Multi-Conveyor LLC of Winneconne, Wisc., recently provided a series of conveyor systems for the reconfiguration of an existing full case transportation line at a major brewery in the Midwest. The original system was a mild steel constructed belt driven live roller conveyor.

Multi-Conveyor worked with the customer’s engineers to add three diverters and several general transport conveyors to divert multiple lines of cased product to a variety of palletizing machines. The customer required the flexibility to choose between palletizers.

The diverting option provided flexibility and helped reduce downtime by keeping product moving during routine maintenance or if a break down occurred downstream.

Multi-Conveyor designed a multitude of conveyors consisting of declining, inclining and horizontal conveyors that dropped into a complex series of existing conveyors that complemented the diverters. The incline and decline conveyor were equipped with friction top belt to keep positive contact with the product during the 15 degree elevation change. They were also designed with pneumatic takeups to reduce belt jumping during the introduction of product onto the conveyors. Their recommendation for the addition of pneumatic belt take-ups eases the stress on the belt and will prolong the life of the belt sprockets.

The entire system is made of mild steel, open top construction and utilizes 2 ¼-in. high aluminum (w/UHMW Cover) guide rails. These conveyors can run at speeds from 100 to 165 FPM at 60 hertz based on a product load of 25 lbs per lineal foot of conveyor (distributed load) with no accumulation.

Multi-Conveyor doesn’t draw the line here. Its capabilities stretch back upstream as far as the washdown loose bottle handling and can stage of production. The most common designs for breweries include but are not limited to accumulation, single filing and general transport. Be sure to stop by the booth and see if their capabilities fit your needs.

Leave a Reply

You must be logged in to post a comment.