Traditionally, metal decoration on beer cans has presented challenges — large can runs were often required, there were few resources for accurately creating designs and the inks had limitations.

But as the craft brewing industry has matured, printers and can makers have realized an opportunity to cater to small run, high detail and easily designed metal decoration services. Enter digital printing. “Not since offset came into a letterpress world has the printing industry experienced a transformation akin to the digital evolution,” notes INX International’s website. INX is the third largest producer of ink in North America, and it has a keen interest in both digital printing and craft brewing.

Let’s take INX’s CP800 software as an example. The marketing material says it’s powered by JetINX Printhead Drive Electronics, Ink Recirculation systems and patented helical printing software, but what that really means is that designers can now easily and accurately design for beer cans with software they already use — with superior quality at very high speeds and with single- or multi-color cost efficient short runs and proofs and prototypes that can be produced in a matter of minutes, offering a unique, fresh solution for direct-to-metal printing.

“Canmakers and design agencies are adopting the CP800 around the globe to complement their current proofing processes,” explained Sarah Jacks, project specialist with INX International Ink Co. “They are finding ways to better serve their customers during the design process utilizing this equipment. Since plates do not have to be created to utilize this proofer, customers have the ability to view their cans to more efficiently finalize graphics and color combinations without the expense and time involved with conventional proofing. Having a tool to help make these decisions in a more efficient manner, allows brand owners, designers and metal decorators to proceed with their current proofing processes and ultimately final production runs to bring those cans to shelves around the world.”

INX has a big focus on the craft brewing industry right now, and it’s helping printers and brewers decorate cans with some important tools that any marketing or design team should have handy when designing for beer cans. First off, there’s INX Color Perfection, a whole suite of tools aimed at streamlining color management on cans. Using the first ever Color Catalog for the metal decorating market, together with advanced digital proofing, color management software and (of course) great ink, can designers now have an easy way to produce artwork for aluminum.

“Utilizing INX Color Perfection allows consumers to have immediate color approval,” said Jacks. “It can take up to several weeks’ time off their lead time that would otherwise be spent waiting for color matches from the INX laboratories. This allows designers a fast and accurate means of color selection and helps provide metal decorators with a cost-effective approach to color management. It allows a fast turn-around on color and some great problem-solving tools for them in combination with their customers.”

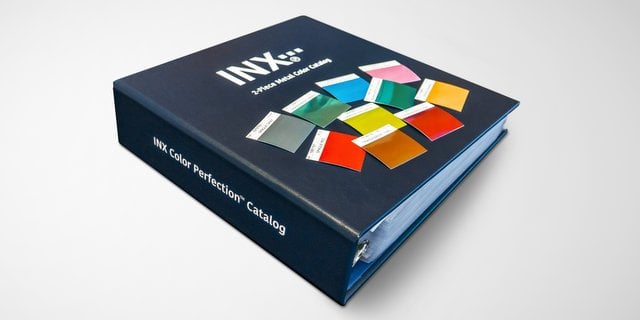

There’s the INX 2-Piece Metal Color Catalog, which is one of those why-hasn’t-someone-done-this-before ideas. It’s the industry’s first true color standard catalog printed directly on metal. Brand owners, designers and metal decorators can select and approve color efficiently on actual metal samples. The INX numbering system includes 600+ removable metal color swatches and access to the same INX colors via the INX Digital Color Library available for most of today’s design programs, including an Adobe Illustrator plugin.

“By incorporating colors specifically suitable to metal deco in the design files prior to pilot or production stages using the INX Color Catalog and the corresponding Digitized Color Library, users are seeing valuable time savings as well as improving communication channels throughout the entire marketplace,” said Jacks. “By referencing these unique INX numbers, users are able to communicate within a network of colors specifically suited for two-piece beverage cans. This helps everyone in the supply chain better understand what customers are looking for compared to using colors created on other substrates.”

Let’s attend INX University

Cans are clearly rolling large in the craft brewing industry these days. They provide protection from light, portability, enhanced sustainability, a better seal for quality and (now) enhanced branding and graphics opportunities from laser-etched tabs and promotional ends to vibrant abrasion-resistant inks and small-run digital printing. Because of this, brewery marketing teams, printers and design firms all could benefit from a trip down to INX University.

INX U is an educational platform that provides access to technical topics on materials, diagnostic information and professional development for virtually everyone involved in the metal decorating chain. From basic education on the artwork submittal process to trouble-shooting guides to color education, there’s great content for anyone who wants great design results on their beer cans. And, there’s more coming this year.

“We have many elements included in our INX University offering that will launch sometime around summer 2019,” noted Jacks. “A key part of standardization is utilizing education. Canmakers, designers, brand owners and anyone involved in the metal decorating market can learn from INX Univeristy. By providing a wide variety of informative educational resources in readily accessible options such as online webinars, we feel that we can help educate the marketplace. We continue to see growth in the craft market, and many of these new members are not familiar with metal decorating. By introducing them to the intricacies of the industry, we can help ease their pain and ultimately successfully launch their product in the market.”

Here are some topics included in the modules for INX University:

- Learn the 10 best practices for decoration setup to maximize print quality. Understand how to identify and resolve problems going above and beyond basic deco setup.

- Learn about the raw materials, manufacturing and quality control of INX 2-piece metal decorating ink.

- Understand how the can plant can reduce applied ink costs and finished can costs.

- Dive into the various can plant process variables which negatively impact costs.

- Discuss the methods for, and advantages of, controlling ink film weights for improved cost and quality.

- And maybe our favorite is the four-part Color Education Series, which includes: 1. Why Measure Color?; 2. Color Instrumentation; 3. Color Measurement; and 4. Color Tolerancing.

The INX website is stuffed full of this type of great info, on top of providing outlines for various print processes as well as different ink offerings.

“Metal decorating is a very unique printing process,” said Jacks. “Understanding how the substrate affects color is key in managing expectations. For example, the aluminum substrate causes colors to appear darker, mute saturation, etc., compared to printing on a white paper.”

That’s the type of insider info INX is providing. While can makers and printers will continue to utilize digital printing technology as a complement to conventional large-scale production operations, the digital process continues to grow in popularity thanks in large part to the craft brewing industry.

“While there are currently not large-scale digital offerings to compete with conventional printing methods — speed wise, cans per minute for example — digital is continuing to gain momentum and offer solutions to markets such as the craft beer market looking to print smaller quantities,” said Jacks.

Leave a Reply

You must be logged in to post a comment.