Challenges abound in the brewing industry today — rising prices and inflation, difficulty sourcing raw materials and ingredients, and an ongoing labor shortage. Amid these difficulties, business owners are trying to figure out how to maintain their current operations with minimal disruption. One of the best ways to keep moving forward is to find ways to do more with fewer resources by adopting technology and automating processes. With the right technology in place, you can save time, improve efficiencies, and get information faster.

Ekos, a top business management software for craft beverage businesses, is focused on helping breweries of all sizes use technology to their best advantage so they can grow, even in challenging times. With a comprehensive end-to-end software solution, Ekos helps brewery owners and managers connect data across the supply chain, providing insights on raw material costs, production trends, accounting KPIs, and sales metrics.

But of course, Ekos is just one part of the puzzle. With greater connectivity comes greater visibility. Ekos sees a few key areas of opportunity for breweries who want to set themselves apart from the competition and find ways to grow their businesses, despite the current challenges.

Read more from Ekos below and be sure to stop by booth #2525 at the Craft Brewers Conference to connect with the Ekos team and get a demo.

Get visibility to combat supply chain challenges

Supply chain challenges are top of mind for everyone. While navigating ingredient shortages, skyrocketing prices, and ongoing supplier issues, breweries have one goal in mind — keep production on track without significantly impacting margins.

For busy breweries with high consumer demand and a long list of sales orders, production staff want to work as efficiently as possible. Ideally, every time you finish a batch, you are ready to start the next one. But what happens when you don’t have the right ingredients or packaging materials on hand? You have to delay your production schedule, which means lost revenue and unhappy customers, or you have to pay expedited shipping to get the materials you need delivered as soon as possible. On average, breweries spend $250 extra on each expedited ingredient order. And when the cost of ingredients and packaging are already rising, that extra cost can have a big impact on the bottom line.

Visibility is key to making sure that you don’t find yourself in these sticky situations. If you use an inventory management software like Ekos, you can see all of the inventory you have on hand, know when you are going to run out and set reorder points when you fall below a certain threshold.

Beyond understanding your available inventory, a business management software can help connect the dots in all areas of the business. Jaclyn Smith from Monday Night Brewing describes the importance of having data all in one place: “Having purchase orders, inventory, sales, and accounting flowing through one system makes Ekos like the middle hub in a big wheel — keeping everything together — as our business grows.”

Connect inventory, sales & accounting data

Technology can help you work more efficiently, but what happens when you have too many systems that don’t talk to each other? To get the insights you need, you (or someone on your team) has to manually enter data in multiple places. This not only takes time, but it also opens the door for data entry errors that could have big effects on your business if you are relying on information in these systems to make decisions.

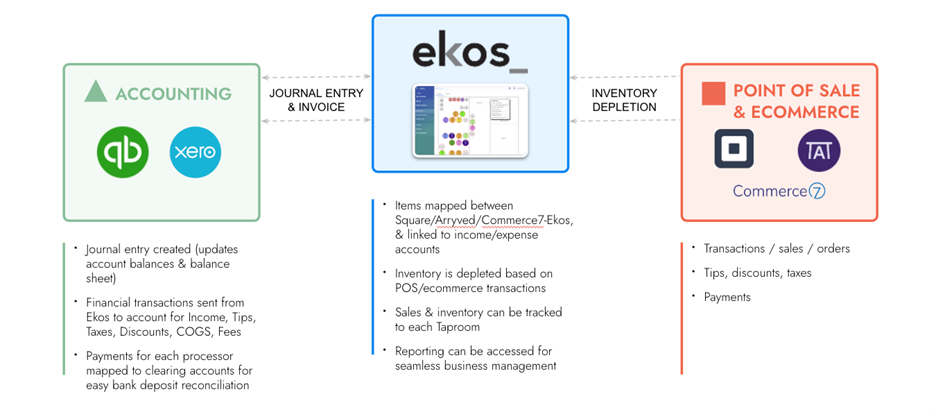

The first step of connectivity is to start with a business management software, like Ekos, to serve as your system of record through which all information flows. Next, we recommend that you connect two vital pieces of software to this core system: POS/ecommerce systems and your accounting software.

By connecting these three systems, you can improve visibility across your business by automatically syncing daily sales to deplete inventory and creating journal entries in your accounting system. Brian Stephens of Iowa Brewing Company said, “Previously, I spent so much time trying to make three things — inventory, POS, and accounting — talk to each other, and it was a nightmare.” Now, instead of spending hours each month reconciling sales from their POS system, his team can get a real-time view of available inventory and sales.

Ekos currently integrates with three POS and ecommerce systems: Arryved, Square, and Commerce7, with more partners to come later this year. On the accounting side, we know that 89% of breweries use QuickBooks (which integrates with Ekos), but we also support Xero users.

Leverage analytics & business intelligence

We recently released the 2022 version of our Building a Tech Stack Report. In this report, we analyzed the technology that breweries and cideries are using to run their businesses. This year’s report is comprehensive — we cover everything from QA/QC tools and ecommerce systems to software for managing accounting or club/subscription programs.

The report highlights many ways that breweries are using software to work smarter, but we identified one opportunity that may help your brewery stand out from the competition: analytics and business intelligence (BI) software. These digital tools turn business data into understandable information that you can actually act on. Our research found that 27% of breweries aren’t using any kind of software for business intelligence and 62% are using spreadsheets.

Large U.S. breweries were the most likely to say they use some kind of solution, whether

it’s spreadsheets or BI software. While the concept of “business intelligence” hasn’t yet become ingrained in the craft beverage industry, that doesn’t mean it isn’t important. Knowing your business inside and out and being able to put that information to good use is key in such a competitive environment.

A good place to start is using reporting and dashboards in your business management software so that you can see important metrics and start to identify themes and areas of improvement. Monkless Brewing, a small brewery in Bend, Oregon, has a connected tech stack that allows the team to extract insights at every touch point from grain to glass to make decisions that will lead to future growth. Owner Robin Clement said, “Other breweries our size are likely not quite as far along in that technology realm as we are and not leveraging the tools completely the way that we do, which has been really eye-opening. I just don’t see any other way to do it.”

Streamline sales with a digital order portal

Every sales leader knows that time is money. The more time sales reps can spend building relationships and talking to customers, the more money you can make. But of course, there is time-consuming admin work, like inputting sales orders, that has to happen behind the scenes . After the customer requests an order, sales reps need to document the order, check that the inventory is available, and schedule delivery. And, usually, there’s some back-and-forth required to get the sales order confirmed.

A digital sales order portal allows customers to place orders themselves. Ekos Order Hub is an online portal that is directly connected to Ekos, so when customers place an order, it automatically creates a sales order in Ekos and depletes inventory in real-time. It also streamlines the approval of sales orders and keeps all communication about orders in a centralized location. Paul DiMarco, inventory manager at Adams Beverages said, “Ekos Order Hub is the simplest way to order in my current world of product purchasing.”

Learn more about Ekos and get a demo at CBC booth #2525.

Leave a Reply

You must be logged in to post a comment.