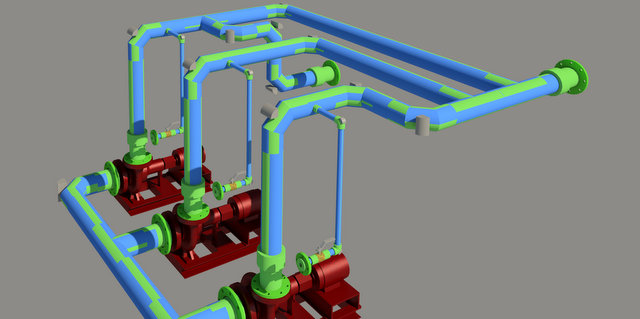

We’re big fans of Aquatherm’s gorgeous green and blue polypropylene-random piping system (PP-R). It has a ton of advantages. Huge cost savings that come from installation speed (those heat-fused connections are fast and flexible friends). Aquatherm pipe weighs 75 percent to 80 percent less than comparable metals, meaning that installers can carry more with less risk of injury. PP-R lasts for decades in piping applications (typically 50 years), and it was originally used for high-purity water and acid-waste systems because of its chemical purity and inertness. In other words, PP-R doesn’t react with most chemicals. It also handles heat and cold easily, so brewers love using it for those chilly glycol lines, but it can carry almost anything.

If we haven’t sold you yet, you should also know systems come with Aquatherm’s 10-year, multimillion-dollar warranty — when installed by an Aquatherm trained installer and with the submission of an Aquatherm pressure test. Aquatherm has released a video that provides an overview of the standard Aquatherm pressure test. The video explains how the Aquatherm pressure test procedure differs from pressure testing traditional piping systems and demonstrates the steps involved in performing the procedure.

NOTE: The pressure test is something the installing contractor should do. However, some brewers do install their own Aquatherm pipe, but the warranty only applies to installations done by Aquatherm-trained installers.

The pressure test has two basic (but important!) benefits for any customer including breweries, according to Ron Rajecki, marketing content specialist with Aquartherm.

- After you’ve got all the piping set up and ready to go, you do the pressure test to make sure there are no leaks. That way in the unlikely event you do find a leak, you can easily fix it before you actually start your brewing operation. This way you don’t have to start and then stop brewing. Also, if there is a leak, the only thing you’re cleaning up is some water that was used for the test, not glycol.

- The pressure test is required to get the Aquatherm 10-year, multimillion-dollar warranty.

The video covers:

- The required and maximum test pressures for various SDRs (standard dimension ratios)

- of Aquatherm pipe

- Choosing a testing medium

- Safety protocols and procedures

- The testing sequence

- What to do if a leak is identified

- Completing and submitting the pressure test record.

Of course, the video is intended for demonstration purposes only. For complete information on the pressure test and warranty, visit aquatherm.com/pressure-test-submission.

Leave a Reply

You must be logged in to post a comment.