Bottles or cans? It used to be a question with several hundred thousand dollars attached to it. Well, it still is, sort of, but you can now answer: Why not both?

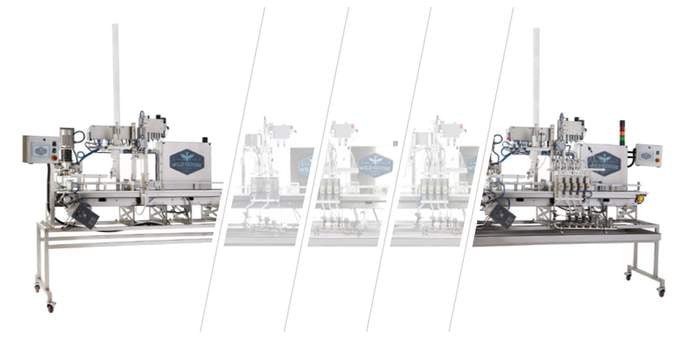

The IC Filling Systems Compactblock is a semi-automatic bottler/capper and canner/seamer. The rinser can accommodate either bottles or cans, while the counter-pressure filler and capper/seamer can be swapped between the two in under 30 minutes. That means you can, say, can your production beers, then put some specialty beers in bombers — all with the same system.

The Compactblock comes in a range of sizes with up to six fillers and is advertised to reach an output of up to 500 bottles per hour. Not too shabby for a machine that, with a labeling and coding add-on, comes in around $65,000.

Throw the best parties with a digital materials printer

The Helix Rotary Digital Printer from InkCups Now is not going to be for every brewery, but those who spring for one will be able to do some really cool labels. That’s because the Helix prints right onto most cylindrical materials — like your bottles and cans — in bold colors and high detail and with an available varnish to give the label a pretty sheen.

At around $200,000 and an output of about 20 seconds per container, you’re going to have to really want it. But think about how cool it would be to do short runs of snazzy labels for parties or customized bottles for weddings and gifts.

“Drop and brew” does turnkey one better

Chris Mulford of Fronhofer Design is a young man with an old soul. “They don’t make equipment to last anymore,” he said. “I want to over design our products so they are truly consistent and reliable.”

Fronhofer’s canning line, for instance, he calls an “idiot-proof, rock-solid” machine that is still very compact. It starts around $85,000, and they can take you from depal to labels for around $168,000.

Their mobile pilot system was getting a lot of attention at CBC. Mulford called it a “drop and brew” system: a skid-mounted, complete 3-bbl brewhouse. It hooks up to your pipes and hoses in minutes, and it’s on rollers, so you can literally roll it out to brew, and then push it aside to store it.

“It’s a better option than cheaper solutions,” Mulford explained, “because it’s the same as your bigger system, just scaled down.” Thus your test batches more accurately reflect what the final product would taste like in your main system.

Fronhofer also offers a cellar skid with the same features. The two together run around $115,000 and have been sold to large and small breweries alike for test and small-batch brewing.

Leave a Reply

You must be logged in to post a comment.