One of the things I love about craft beer is how many brewers value things like organic ingredients, sustainable energy use and fair employee practices. Of course, they also care a lot about very practical matters like cost and space. As I roamed the massive exhibit hall at the Craft Brewers Conference and BrewExpo America, I found several producers trying to negotiate these diverse needs for craft brewers.

The increasing proliferation of such products only further testifies to the growing strength of the craft sector and the fact that manufacturers and producers see lots of opportunity (read: If you’re not sure they have what you need, you may as well ask. They’ll probably go to great lengths to serve you.).

Here are some examples of innovations you may want to look into or keep an eye on.

Amoretti Craft Purée

I have to admit, when I saw the booth with a couple rows of bottles with those big white pumps on them, I thought this was a consumer product akin to the syrups they use at coffee shops. I imagined a bartender taking my beer and turning around to pump a shot of black cherry into my IPA, and I wasn’t exactly excited about it.

Amoretti even put a small bottle of the stuff into our conference swag bags. I’m not sure I would have tried it, myself, except that I knew I couldn’t sneak it on the plane (well, that turned out to not be true), so I thought I’d give it a shot. I liked it more than I expected. I tried a bit in a pale, an IPA and even the conference collab saison, and it worked pretty nicely in each.

But according to Marketing President Maral Barsoumian, this is definitely a product for breweries. It is designed to be added to the batch like any other extract or tincture such as you might get from Lebermuth or Oregon Specialty Fruit (also CBC exhibitors).

The big difference, to my eyes, was the pumps, then. The concept of the pumps, Barsoumian explained, is that these purées are calibrated for precise taste testing. By adding one pump to a 12-ounce pour you get a reasonable preview of what the finished brew will taste like.

There’s certainly a convenience factor there, but I did notice on the website that they are in fact marketing the pump-bottles to consumers as a way to “customize your favorite beer, wine, champagne or alcoholic beverage.”

Fair enough. If you can sell something to both producers and consumers for similar but distinct purposes, it makes sense that you might do that.

The future of barrels is not what you think

You might think it’s never been a better time to be a cooper. Alcohol beverage is doing pretty well overall, and with the rise of craft distilling, barrel-aging beers and sour beers, barrels are in demand. There’s only one problem: We’re running low on oak trees. We have been for a while, in fact, and we may be in for some time until the next crop of trees comes of age.

The solution: Stainless steel. Sort of.

The solution: Stainless steel. Sort of.

The Squarrel Barrel (just go with the name) is a square, stainless-steel frame that fits 12 slotted, charred, oak staves. Squarel Barrels market it as a barrel that pulls more flavor more quickly while using less actual wood.

But wait, it gets better: Most oak trees only yield two to five barrels, and much of the tree goes to waste. The Squarrel staves can be made from this leftover wood. It’s just as good because it’s from the same tree. And because they slot the staves (picture a reverse guitar fretboard), more wood is exposed and extraction happens more quickly.

So, it’s more efficient for the environment, and it reduces waste for barrel makers — they can literally make more barrels from each tree.

It really does sound too good to be true, but according to Tom Ohlin of Minnetonka, who had a display model at his booth, the TTB has already approved it for whiskey, so it has some official recognition.

The gamble, of course, is that there’s still enough connection to the traditional supply chain (tree > cooperage > distillery > brewery) that producers will buy into a new aesthetic. Then again, if an oak shortage keeps shooting traditional barrel prices higher, a cheaper oak solution will start to look pretty good.

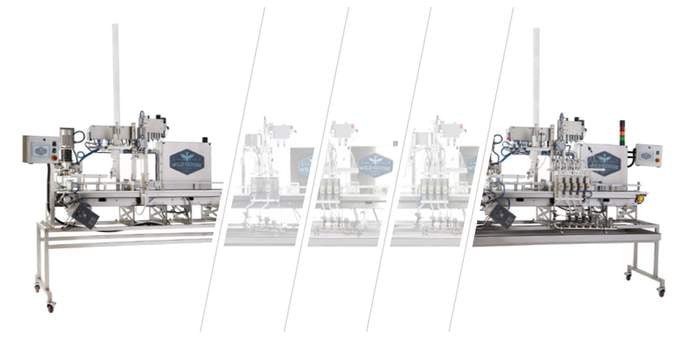

The incredible transforming filler

On the next page! (along with a printer and “drop and brew” pilot system)

Leave a Reply

You must be logged in to post a comment.