The ZIEMANN name carries a lot of history and brand equity (maybe that’s why it’s all capped like that). In 1852, August A. Ziemann established a coppersmith workshop, and eight years later his first brewhouse was delivered to China. The company’s been building brewing equipment and exporting it for more than 150 years. Since 1947, HOLVRIEKA has been a pioneer in the manufacture and installation of stainless steel tanks. Today, the combination of ZIEMANN HOLVRIEKA (both owned by CIMC Enric) can provide some of the most advanced and high-quality turnkey brewing operations and systems in the world.

Plus, they’re just cool to hang with. We always catch up with the ZIEMANN HOLVRIEKA crew at the Craft Brewers Conference. We’ll discuss ZH’s newest piece of next-gen brewing equipment (T-Rex, anyone?) or tap their decades of knowledge for some solid CBB articles. In fact, the company is promising to change the game dramatically with a secret new product launching at BrauBeviale today (see the sweet serpent-themed teaser here).

ZH is expanding as well. The company recently opened a new office. It’s operating from three sites in North and South America: Miami, the Columbian capital of Bogota and now, just announced, San Diego. Who’s running that new outpost? Beer brainiac Ralph Schneller-Reindell; he was recently promoted to head the USA, Canadian and Latin American sales regions in his capacity as vice president of sales. At our first Craft Brewers Conference, Schneller-Reindell was kind enough to give the newbies at CBB some quality interview time.

So when we heard the good news, we congratulated Schneller-Reindell on his promotion. And then we took that opportunity to ask him a few questions, and his answers were as insightful as ever. Enjoy them below, and we’ll keep you updated on the BIG ZH REVEAL at BrauBeviale.

CBB: Ralph, thanks for taking the time, and congrats on your recent promotion. It seems there’s a lot happening at ZIEMANN HOLVRIEKA today. It’s an umbrella company for a number of different brands and technologies. A lot of readers are familiar with ZIEMANN, but what products and services does the company offer today to American craft brewers?

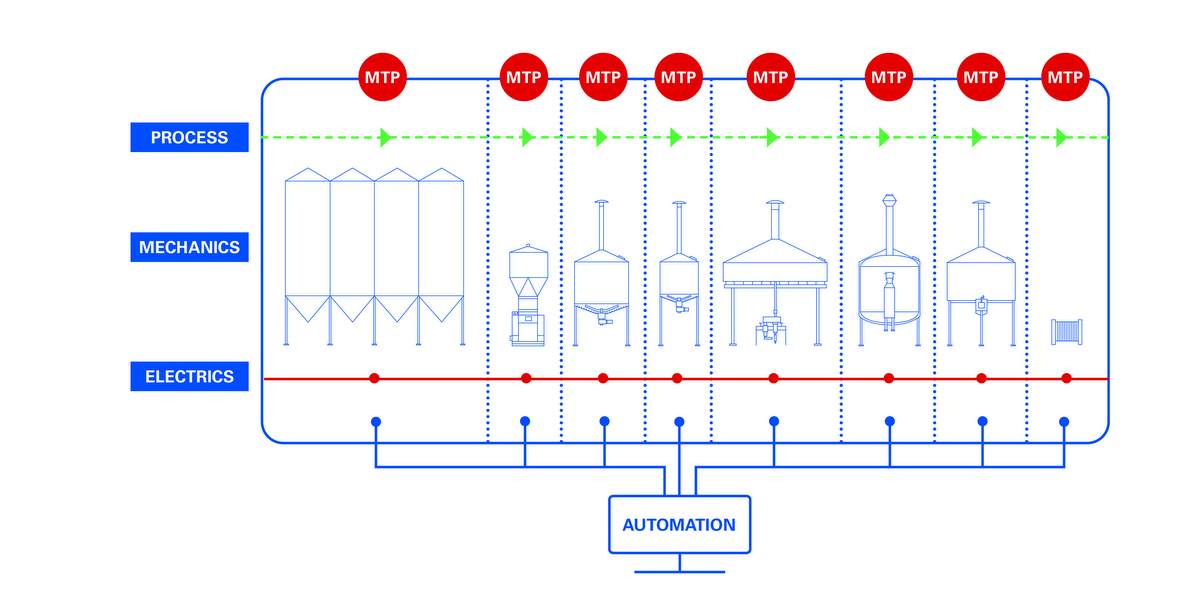

S-R: Since 2012, ZIEMANN has been part of a group of companies. Last year all these companies changed their formal company name in order to make it clear that we all act jointly. Our portfolio is still the same: We offer turnkey breweries from the malt intake up to bright beer tanks. But now, in our group, we can offer better services with our entities in Europe, Asia and the Americas.

How will this new U.S. branch of ZIEMANN HOLVRIEKA help spread the ZH message and products?

It is a first step to increase our market presence both in North America and in Latin America. Of course, we will strengthen our close relationship to our long-term customers, and we will intensify our discussions with potential customers.

For a craft brewery just starting out, what advice would you give when it comes to picking and choosing a brewhouse and vessels?

I have three pieces of advice in mind: 1. Think big, start small: Consider your future growth. 2. Choose a flexible solution that enables you to stay creative; 3. Decide in favor of quality. When you consider reduced running costs, it pays off.

How important is flexibility?

Flexibility is not only important, it is crucial. No craft brewer can afford a limitation of his or her creativity. Most standardized solutions may be attractive at first glance, but it restricts your technological freedom.

How can novice buyers find and judge a product? That can be difficult. How can they judge if this meets their expectations for efficiency, quality and environmental friendliness?

Ask one simple question: Can you prove your promises? A company like ZH is experienced in building highly efficient plants, in producing required qualities and in creating sustainable solutions. Everybody can benefit from our long-term and proven experience.

How do you think ZIEMANN HOLVRIEKA stands out from the competition today? Do you offer some unique products and technologies that you can talk about?

During the last few years we have launched a lot of new technologies — our T-Rex, Shark, Colibri, Lotus, Ice Age systems. We feel this is pretty unrivaled in the brewing industry. Our tanks are well-known for their quality, and our 21st century concept anticipates the requirements for sustainability. We can create the infrastructure to convert any brewery completely or partially in order to integrate renewable energy sources and sustainably, thus reducing resource consumption.

Being a global brewing provider, what trends do you see in the American craft brewing industry right now?

The first trend: Brewers want to add hops and other raw materials at diverse process steps. That second trend: Brewers want to save energy and resources and use renewable energies. For both trends, ZIEMANN HOLVRIEKA has tailor-made solutions at a price level of standardized solutions.

How does America compare to the rest of the world when it comes to purchasing certain products or services?

Brewers in the USA emphasize the high quality of their beers. This leads to the request for high-quality brewery plants.

What ZIEMANN HOLVRIEKA product has you the most excited right now?

That’s a tough one. Too many choices. Focusing on our products that are currently available I would pick the T-Rex. It has wet and dry milling, even with the same machine, and it has on the flight gap adjustment and roller speed control. It can be used for lauter tuns and mash filters, and the system is suited for all types of raw materials. Plus, it has less energy requirement, and it’s faster and easier to maintain. I really think the T-Rex mill is the best example of what our R&D team is focusing on — revolutionary improvements that give the craft brewers flexibility and process control. And I almost forgot, but we have even developed a new hop back and a new dry hopping system. These and other products are in the pipeline of our R&D team.

When considering the craft brewing industry, what ZH product or technology will be a game-changer in America’s independent brewing industry?

Our latest innovation will “change the game” dramatically. Since we will be presenting it for the first time at the BrauBeviale in November, I won’t give away any more than this: In hall 6, booth 100, we will be showcasing a completely new, revolutionary process in beer production, which offers extensive technological and economic advantages. Visit us in Nuremberg!

Click here to see what’s in store for ZH at BrauBeviale.

We discuss brewhouses and beyond with a ZIEMANN HOLVRIEKA beer expert https://t.co/C9eW3Osz3K via @craftbrewingbiz

We discuss brewhouses and beyond with a ZIEMANN HOLVRIEKA beer expert https://t.co/j5q60rSE20 #beer #craftbeer