In this series of articles, Amy Todd, owner and operator of Zymology Labs, a third-party beer testing lab, who also works part-time in the lab at Zero Gravity Craft Brewery, gives us a detailed ground-floor view of the day-to-day lab routines that separate quality craft breweries from the pack.

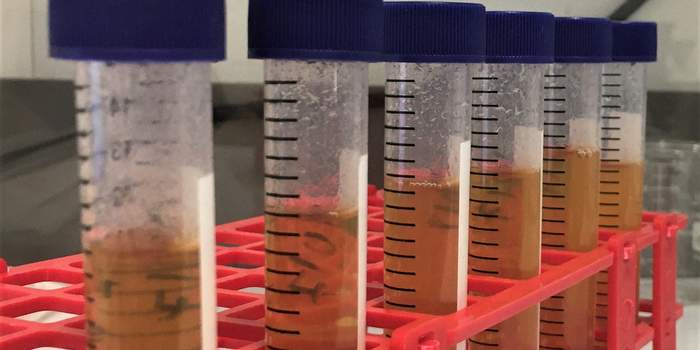

- Part 1: Sampling

- Part 2: Understanding HLP Tubes

- Part 3: Sensory Panel Setup, Tasting Tips and the Triangle Test

So far I’ve talked about collecting samples, using HLP media to look for bacteria and setting up and running a taste panel. I’ve got quite a bit to cover as we go, but let’s take a step back for a moment.

Just as in any job, there are some things I do every day, some things only once a week and some even less than that. Many of my tasks in the lab are multi-step procedures. How do I make sure I’m carrying out tasks correctly, and the same way that I did last time? Wouldn’t it be great if with the flip of a page, or a click of the mouse, you could have all the information you needed to perform a specific task right in front of you, complete with pictures?

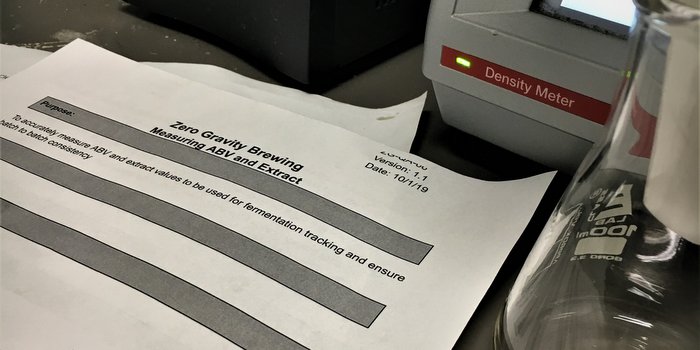

Today in the lab I’m updating Standard Operating Procedures (SOPs). I like to do this every so often to make sure they’re current and to see which ones still need to be written.

Writing out all the steps involved in a process gives everyone an easy to follow list of how to perform a specific job in the brewery, complete with safety precautions, materials needed, a list of references and even pictures!

Excited to dig in to SOPs?

….

I know, SOPs are not fun to write. You’d rather manually grain out the mash tun. I’m sure some people love to write them, but I am not one of those people. I do, however, see the value in a written document outlining all steps involved in a particular procedure.

I’ve realized over the years that I am a rule follower. I always use my blinker, even in an empty parking lot. I wait until my boarding group is called before I get in line at the gate (with a bag that actually fits under the seat). When the cashier accidentally rings me out for one pack of gum when I had two, I let her know. So, while I might not like writing SOPs, I do like following them.

Coming from a science background, standard operating procedures have always been, well, standard, in all my previous jobs. It wasn’t until I started the lab at Zero Gravity that I found myself in a position with no SOPs already in place. Now, I’ve had plenty of experience updating, formatting and adding to SOPs, but I was starting from scratch in the lab.

Well, not scratch, I guess. I use the American Society of Brewing Chemists Methods of Analysis for all my lab-based procedures. If you’re not a member of the ASBC go sign up. It’s $199 for a one year membership and you get access to all their methods of analysis. Which is basically how to do everything you could ever need to do in a brewery lab.

If you don’t have time to re-write SOPs in your own format and your instrument or equipment comes with an SOP, or you want to use an ASBC method, start there. Make sure you keep it somewhere so that it’s available to everyone. When you have time you can re-write these steps to fit your own format and any little tweaks you’ve added or taken away to match exactly how you perform the procedure in your brewery.

Example of SOPs updating

When we got our DO meter, I copied the cleaning and use procedures into the format I’m used to using. I then referenced the manual and where brewers could find more information if they needed. Since the calibration requires going through a series of screen prompts I included a lot of pictures. I made a separate SOP for cleaning and calibration, one for using it on the fermenter and brite tanks and another for testing cans. These three things can be performed independent of each other so I split them out into three separate SOPs.

No need to start from scratch every time someone goes to clean a keg or do a cell count. If you have figured out the best way to do that at your brewery, on your system, provide everyone with a guide to do it the same way.

To be honest, I do not have SOPs written for everything I do in the lab. I have most, as well as a list of what ones I already have and what ones need to be done. This is shared with everyone at the brewery on GoogleDrive and includes dates SOPs were updated or written. Ideally I would have a regular schedule where I update SOPs and finish writing new ones, but I’m not there yet. Right now I work on them when I have time.

Any time I make a change, I log what the change was, why I made the change and when — right in the revision section at the end of the SOP. It’s okay to make changes to how you do something as you get new equipment, learn a better way of doing something or become more efficient. The important piece of making any type of change is to make sure it’s communicated to everyone, and make sure you note when the change occurred. A change in the brewhouse might lead to a result you didn’t expect and keeping records of all changes will help when troubleshooting.

I follow the same outline for each SOP, but depending on the task and what type of equipment I’m using I might need to alter that a little bit. For something like performing daily checks on the Alcolyzer, I have a lot of pictures since most of that is following computer screen prompts.

The general format I use is:

- Title

- Purpose

- Who

- Safety

- Materials

- Procedure

- References

- Revisions

I have a blank template saved that includes a heading and revision section at the end. This way when I’m ready to start a new SOP I feel like I’ve already started, or I’m at least not starting from a blank page.

So what goes into each category?

Title/SOP Number: Come up with a title that tells you exactly what the SOP it is about, like “Keg Cleaning.” Your brewery might have a specific way of titling SOP such as a category header of “Brewing” or “Lab.” I put my category code along with an SOP number, such as “ZG-QA-01 HLP Prep”

Table of Contents: Depending on length and complexity of your SOP, you may want a table of contents. None of my SOPs include a table of contents, but I do have a list of SOPs saved in the SOP folder.

Purpose: Why is this particular task being done? How does it help the brewing process as a whole? When people know why they are doing something they put a little more thought into the task. Go a little deeper than just saying the purpose of this SOP is to explain how to make HLP media. You can absolutely say that, but include that HLP testing helps screen for microbial contaminants in the brewery that can spoil your beer.

Who: Who will be performing this particular task? This may change over time and that’s fine. Your brewer may do this task now but as your brewery grows this duty may shift. Update your SOP to reflect that change when it happens. Use titles instead of specific names as rolls can change.

Safety: List any safety precautions that must be taken when performing this procedure. What type of PPE (personal protective equipment) must be worn. Are there any trainings that must be done beforehand, such as confined space or forklift training? What chemicals are being used? Review and reference the SDSs. Think about everything that could go wrong.

Someone who picks up this SOP might not have any experience in a brewery, which can be a very dangerous place. Don’t assume everyone knows something that may be second nature to you and include it in the SOP.

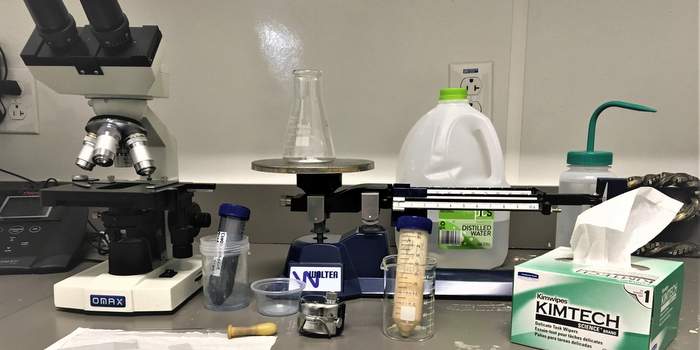

Materials: What do you need to perform this task? What tools, equipment, safety gear or chemicals will you be using? You may want to include where these are stored if not in an obvious location. I use a bulleted list for this section.

Procedure: This will be the bulk of your SOP. What are the steps involved in this procedure. Determine how detailed you want this to be. The more detailed, the more likely it will be done exactly how you want it done. If you leave too much open for interpretation, everyone will do it their own way. Too detailed and the SOP might just get skimmed. Find the right balance. You could even have a detailed section, then a quick checklist to follow for someone who’s more familiar with the procedure.

Write this section while performing the task and take pictures as you go. If you’re writing from memory, you might skip over steps you do automatically but are very important for someone doing it for the first time. If it’s a task you don’t normally do, make sure you bring in whoever does perform the task and have them review to make sure it’s what they actually do.

Your procedures need to reflect what you actually do, not what you’re supposed to do or what you used to do. Remember, it’s okay to make changes as your brewery grows and evolves, just make sure you update your SOP when any changes to the procedure are made.

Standardizing your SOPs process

Getting all your SOPs in writing is a big process and not one that you need to do all at once. I still have SOPs I need to write, but it’s wonderful when I already have them in place when I’m training someone new. Ideally you’ll have them written before you need them.

Start by making a list of what SOPs you want to have in place. Might as well knock out the easy ones first. See if any of your equipment comes with an SOP you can use for now or tweak to make it your own.

If your brewery already has some SOPs in place, use that as a template and customize it for each task. No SOPs in place? Make a list of what you need. Start with your area of expertise and find what works for you.

To make consistent beer, you need to follow the same recipe AND procedures every time. Having SOPs in place makes it easy for you and everyone else in your brewery, to follow the same set of procedures. Taking the time to write SOPs builds a solid foundation of safety, quality and consistency. Every brewery is different and has their own way or doing things. Just make sure at your brewery those things are done the same way by everyone!

Amy Todd is the Owner and Analyst for Zymology Labs as well as a lab manager for Zero Gravity Craft Brewery in Burlington, Vt.

Leave a Reply

You must be logged in to post a comment.