I like machines. I like construction equipment. I like diesel engines. I like robots. I also very much like brewing equipment. I geek out over mills and mash tuns, eductors or accumulation tables and boilers and basically entire brewhouses. I also handle the Equipment department here at CBB, and these are my favorite equipment features that peppered our brewing site over the last 12 months.

Last second gift ideas: Craft beer professionals pick their favorite pieces of equipment

Beer is the gift that keeps on giving the whole year (it’s not a membership to the Jelly of the Month Club). Yet the magic of beer actually comes from a fairly unmagical manufacturing process that relies on loads of science and equipment. The brewhouse and packaging hall are basically a warehouse of application-specific machinery — brew kettles, water tanks, mash mixers, wort chillers, lauter tuns, fermenters, compressors, heat exchangers, brite tanks, piping everywhere, rinsers, fillers, conveyors, accumulation tables, palletizers, depalletizers and eventually, after way more equipment than we mentioned, you get your six-pack of beer. Read more here…

Keep’em separated: Discussing small brewing centrifuges with Germany’s Flottweg

Ridiculously big trade shows usually call Münich home. The Neue Messe München exhibition center (a train ride from the German city center) is one of the largest trade show spaces in the world with 16 halls of exhibition space and an absolutely ginormous outdoor area. As proof, the world’s leading trade fair for the beverage and liquid food industry — called “drinktec” — will take place over five days (Sept. 11-15) at the Neue Messe München exhibition center. This beverage show only happens every four years, and it draws some of the biggest manufacturers, suppliers, distributors and brewers working in the world of beer. Read more here…

Internally-fed rotary screening systems: Economical pretreatment solutions for brewery wastewater

There’s a good chance that the last beer you drank was a craft beer. With more than 5,000 craft breweries in the United States and nearly two more opening every day, craft beer is on tap for more and more Americans. The country hasn’t seen a surge in locally owned and operated breweries since the 1880s. Yet with this growth in demand for craft brews comes an increase in challenges for the less glamorous side of beer production — the wastewater created by the brewing process. Read more here…

Five awesome applications for robots in a craft brewery

What tasks in a craft brewery can you do with a collaborative robot? Here are five great options to improve the efficiency, consistency and safety of manufacturing in the beverage industry. We showed in a previous post how craft brewers can really benefit from collaborative robots (a.k.a. cobots). These new robots can help to overcome the challenge of scaling up a brewery, without compromising the integrity of the beer. They work alongside you and don’t need safety fences. But, which tasks should you give to a craft brewing cobot? Here are five great applications to get you started. These applications are also relevant to other beverage manufacturers, so read on even if you’re not a brewer. Read more here…

Vessel hygiene: Microbial monitoring and detection methods for brewing equipment

This rising demand for beer has increased the pressure on breweries to produce barrels of superior quality beer within a short period of time. Only a beer sommelier can validate the fact that it’s not merely the hops, the malt and the yeast but also the production process and the faultless sanitation that impact the quality and consistency of the end product. Sanitation is fundamental to the brewing process. In fact, most brewers spend the early years of their career merely learning to clean the brewery. The U.S. FDA has made it mandatory for all breweries to have an active GMP (Good Manufacturing Practices) program in place. Breweries are required to ensure that their hydrometers, tanks, hoses, kegs, drains and floors are sanitized each day as per the GMP standards, as it critically affects the quality of the finished product. Read more here…

A brewery pump selection and maintenance guide (from centrifugal to positive displacement)

Both large commercial and smaller craft beer breweries use sanitary pumps to transport viscous and non-viscous liquids during the beer-making process. Their important role in a brewery’s operation means careful attention to the selection is essential, and once put into operation, pumps must be well-maintained to sustain peak performance. Pumps can be divided into two basic categories: centrifugal and positive displacement. A centrifugal pump transfers centrifugal or kinetic energy into a liquid in the form of velocity and pressure. A positive displacement pump transfers a precisely measured amount of liquid from the inlet to the outlet for each rotation or stroke of the pump. Read more here…

Pack Expo 2017: A rundown of cool beer equipment we eyed on the tradeshow floor

As I wrote elsewhere, original equipment manufacturers (OEMs) weren’t as craft-focused at this year’s Pack Expo as last year, but I spoke to many who had craft beer experience and were hoping to do more business in this sector. There weren’t exactly a lot of new offerings, but if you’re in the market for new equipment, this will give you an idea of some OEMs who have worked with your colleagues and would love to work with you. All info gathered at Pack Expo Las Vegas 2017. Read more here…

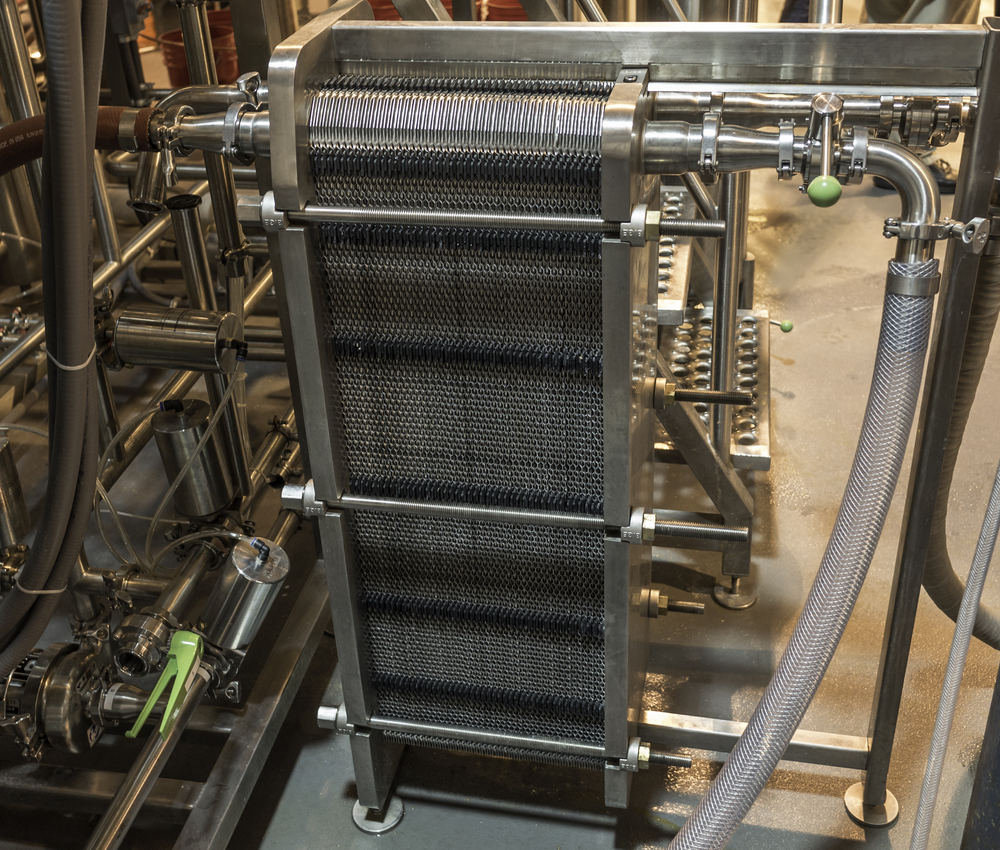

Learn how heat exchangers are used in beer and cider production

With the growing popularity of craft beers, microbreweries and products made with all-natural ingredients, operations need to be as efficient as possible to keep up with the competition. Whether you’re producing beer or cider, one of the most vital pieces of equipment for increasing efficiency is a heat exchanger. So, before we crack open a cold one, let’s discuss the brewing process, the challenges it poses, and how heat exchangers help brewers tackle those challenges. Read more here…

We found some ways to do more brewing, filling, aging with less at #CBC17

One of the things I love about craft beer is how many brewers value things like organic ingredients, sustainable energy use and fair employee practices. Of course, they also care a lot about very practical matters like cost and space. As I roamed the massive exhibit hall at the Craft Brewers Conference and BrewExpo America, I found several producers trying to negotiate these diverse needs for craft brewers. The increasing proliferation of such products only further testifies to the growing strength of the craft sector and the fact that manufacturers and producers see lots of opportunity (read: If you’re not sure they have what you need, you may as well ask. They’ll probably go to great lengths to serve you.). Here are some examples of innovations you may want to look into or keep an eye on. Read more here…

Creative equipment choices: Learn how to buy a beer foeder with Schlafly Founding Brewer Stephen Hale

How do you capture and then continue to recapture the magic of a great beer? It’s a lot of science, of course, but it’s also a lot of showmanship. Unfortunately, the art of making a unique beer is becoming more and more difficult with 5,300 plus breweries in the United States, so brewers are increasingly looking to experiment and use that experimentation as a marketing opportunity. To help, they’re investing in creative equipment choices. For starters, barrels can add both unique characteristics of wood and/or the flavor of what was previously housed inside that wood into a beer. Barrels are also beautifying additions to your brewhouse or aging cellar and a great opportunity to create the artistic ambiance that customers will associate with your top tier beer brands when they visit. It doesn’t stop at barrels. A lot of breweries are capitalizing on unique and artful equipment. Read more here…

Flooring for breweries: What to consider for style and function

Breweries range in size from small, family-run businesses to large manufacturing operations that ship their goods worldwide, but one thing that all breweries have in common is the need for a durable, safe flooring system that can withstand the demands of the industry and meet USDA standards. If the facility also has a public tasting room or other area open to the public, various flooring systems in different spaces may be necessary. Function and aesthetics are both critical points to evaluate when choosing a flooring system for a brewery concern, whether for large production or a smaller craft operation. Read more here…

Digital printing: In-brewery solutions for beer bottle, can label production

The label talk at last year’s Pack Expo was all about short runs, i.e., ordering something south of a truckload of labels. Short runs mean smaller craft brewers can more easily afford labels because you only need to order roughly what you’ll use. You pay more than for a larger order, but you don’t need to have the capital for a large run, and you don’t need to store huge rolls of unused labels. Digital printing made this possible by doing away with the need to create a new plate for each label. With digital, you just need the label stock and a solid printer, and you’re off and running. Most printers now offer both flexographic and digital printing, meaning more options to fit your aesthetic and your budget. Read more…

Hector Aguilera says

Rodrigo Nogueira