You can tell Karbach Brewing Co. appreciates Germany’s rich history of beer knowledge and design. First off, Karbach is named after Karbach Street in Houston, Texas, which the brewery sits on, but it’s also a village in Bavaria (“we hear they drink a lot of great beer there,” says the Karbach site). The site also proudly mentions Karbach’s “German training,” and recently, we even heard the company is importing the first Ziemann turnkey brewhouse for a U.S. craft brewer. Ziemann is the famous, one-stop brewing equipment manufacturer from Ludwigsburg, Germany, that’s been serving the beer industry for more than 160 years.

As part of the brewery’s capacity expansion, Ziemann will also install a tank farm consisting of six fermentation and storage tanks.

“Since 2003, Ziemann has been successfully supplying tanks to craft breweries in the USA,” said Eric Warner, yeast rancher from Karbach Brewing. “The high quality and reliability in combination with the great know-how of the process — from malt handling to bottling — makes Ziemann the ideal partner for us.”

Karbach Brewing was founded 2011 and since then, this craft brewer has been writing a remarkable success story: after two years they already produced 18,000 barrels (bbls). For 2014, a sales volume of 35,000 bbls has been forecast. At 40,000 bbls per year, the current brewhouse had reached the limits of its capacity. Therefore, Karbach Brewing will expand its production capacity in cooperation with Ziemann with a new brewhouse and tank farm. The project will feature a restaurant area with a prominent view on the showpiece brewhouse from Ziemann.

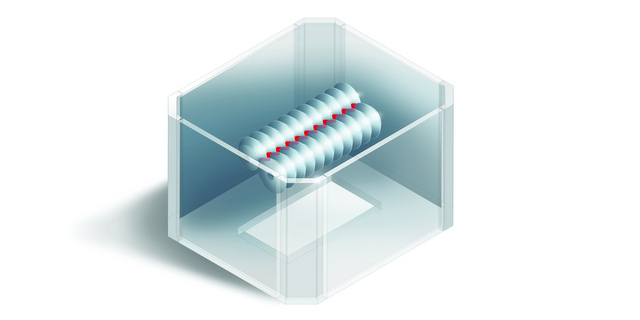

Equipped with the latest innovations for craft brewers, the new brewhouse will feature these three new technologies:

- “Colibri,” the gentle and effective mash mixer

- “Lotus,” designed with the optimized Ziemann lautering process

- “Shark,” the gentle but thorough and energy efficient wort boiling

This Ziemann brewhouse will be producing up to 12 brews per day with a cast-out wort volume of 120 bbls and is designed with a special focus on the requirements of craft brewers, focused on maximum versatility and flexibility. Besides brewhouse and tanks, the Ziemann supply includes the automation of the system as well as the integration of the malt handling.

As Warner pointed out, one of the key decision factors was the short installation time due to the very high degree of prefabrication in the Ziemann workshop in Germany. From unloading the vessels to the first brew, the installation will be completed within four weeks. The new tank farm, consisting of six CCTs with a capacity of 600 bbls each, will boost the annual production capacity of the brewery to 100,000 bbls. Ziemann will be responsible for the supply and installation of the tanks, including the catwalk system.

The future addition of fermentation tanks will provide a production capacity of more than 300,000 bbls per year. All work in the brewhouse as well as in the cellar area will (hopefully) be completed in the third quarter of 2014.

Ziemann delivers its first U.S. craft brewhouse to Karbach Brewing http://t.co/8aVFVOTTpE via @craftbrewingbiz

Jacob Garvey liked this on Facebook.