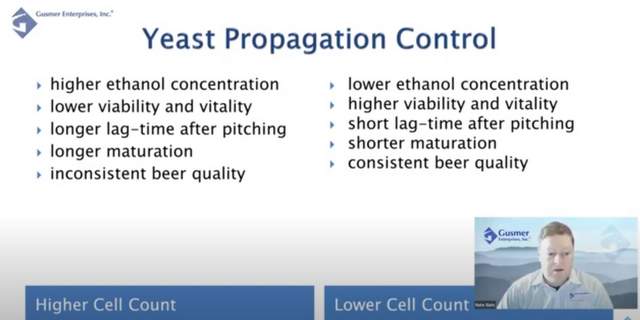

Why do you need to measure dissolved oxygen (DO) content during the beer making process? A) To gather performance metrics, ensuring the oxygen needed to enhance yeast propagation and fermentation; B) Oxygen impacts flavor stability (you don’t want that old, musty vibe); and C) DO affects shelf life.

Controlling oxygen content during the brewing process requires precision, and it certainly helps to have precision instruments. The crew from Gusmer Beer explains this and more in the excellent webinar above. Gusmer provides brewing expertise focused on fermentation, filtration, processing aids and beyond, selling everything from lab equipment to entire brewhouses, often as a distributor.

Gusmer is the sole distributor of a handy DO solution. The Hamilton Beverly portable DO meter is specifically designed for at-line and laboratory use in small and midsize breweries. The Beverly incorporates Visiferm DO ECS probe sensors (learn what those are right here) to create a robust, all-in-one unit that can be used for checking DO in all types of beer processes — post fermentation, just prior to packaging, wort aeration, yeast propagation, and (of course) deaerated water.

There’s a lot in this 30+ minute webinar. Learn about Gusmer and Hamilton. Deep dive into the brand’s DO meter. Learn about sample points, general tips, calibration and troubleshooting. This video covers a wide range of DO dos and dont’s when it comes proper measuring, tips for usage and common problems and solutions.

Leave a Reply

You must be logged in to post a comment.