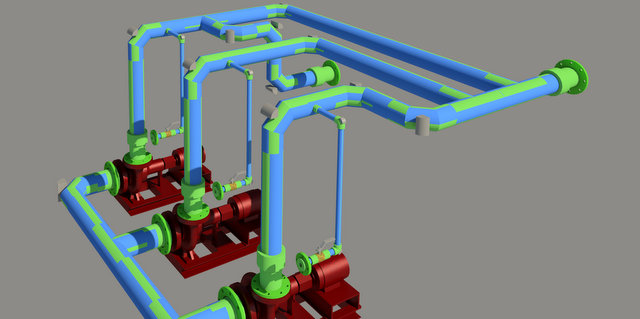

What’s that green and blue pipe, you ask? Ahh. It’s a polypropylene piping system (or PP). The brand is called Aquatherm. Catches your eye, doesn’t it? Besides its bright, colorful appeal, this unique plastic pipe offers numerous benefits in a brewery, say, compared to metal or other plastic piping systems.

For starters, PP is much lighter than metal. It will not corrode or scale, and it is connected by virtually leak-proof heat fusion, which is quite useful as a brewery’s infrastructure can be an annoyingly complex set of zigzags (as you know well).

Are any brewers actually using this clearly-sent-back-from-the-future plastic piping system? Oh yes. Denver’s Epic Brewing Co., Ocean, N.J.’s Kane Brewing Co., Wise Man Brewing out of Winston-Salem. N.C. Smith and Lentz Brewing in Nashville, to name a few. Just watch the video below.

Large and small brewers from coast to coast are embracing Aquatherm pipe for applications such as glycol lines, domestic water, heating and cooling, reclaimed water and CO2 lines. I could go on, but I can see that you’re quite busy. But before you go, here is a detailed list of benefits for Aquatherm’s colorful PP piping system in breweries. Just in case you need it handy.

The benefits of Aquatherm’s polypropylene piping

- It will not leach any contaminants into the fluids that it carries.

- It has a 60-year lifespan and is fully recyclable.

- Aquatherm pipe is an ideal choice for glycol systems because the chemically inert PP pipe has a very high resistance to the chemicals in the antifreeze.

- Fusion outlets allow for inexpensive and easy system expansion. These allow branch lines to be installed when the pipe is already in place. The pipe is simply drilled into with a specially designed bit that removes the PP material and the fusion outlet is welded into the drilled hole. They are typically less expensive than tees — and, again, are virtually leak-free.

- Aquatherm also offers an exclusive hot tap tool that allows brewers to easily add a new line or a new fermentation tank without shutting down the cooling to the rest of the brewery.

- Aquatherm’s fusion welding process is quick and easy, it introduces no additional materials or any contaminants into the system, and it yields a very smooth-flowing inside diameter of the pipe. And, as no two fermentation tank installations are exactly alike and the world is not made up of perfect angles, fusion welding also provides flexibility to accommodate minor angular variations during installation.

- Despite the ease of fusion connections, Aquatherm is still a craftsman’s system. While a level of plumbing/pipe fitting expertise is necessary for a proper installation, many brewers have completed the Aquatherm training and partnered with a local installer to save money on the installation and future expansion and maintenance.

To learn about even more benefits, hop on over to Aquatherm’s website right over……………here!

Sean Roach says

Chris Dooley