Creating energy from waste is a noble goal that a few forward-thinking craft breweries have already embraced. At New Belgium Brewing Co.’s on-site Process Water Treatment Plant in Fort Collins, Colo., the brewery uses microbes to clean all of its production wastewater through a series of aerobic (with air) and anaerobic (without air) basins. A byproduct of this process, methane gas, is harvested and piped back to the brewery, where it powers a 292-kW combined heat and power engine, reducing up to 15 percent of New Belgium’s electrical needs.

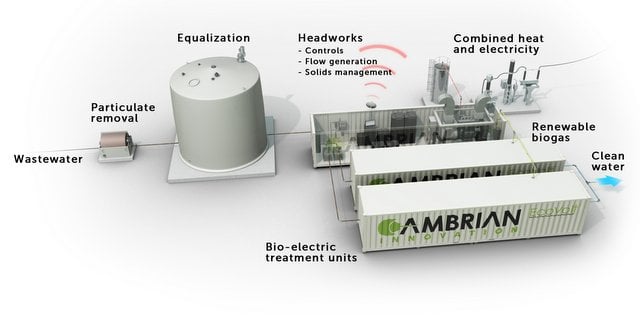

Even more futuristic, energy-generating wastewater products are being engineered specifically for the brewing industry. We met the big brains behind Cambrian Innovation back in 2014 at the Craft Brewers Conference, specifically sitting down with Matthew Silver, Cambrian CEO and holder of three advanced degrees from MIT. Silver and his crew at Cambrian Innovation sell the awesomely innovative EcoVolt system, which employs a proprietary bioelectric technology to treat brewing wastewater while generating biogas energy, transforming waste into an asset. We reported Bear Republic Brewing Co. was the first brewery to purchase the EcoVolt system back in early 2014; we recently discussed how Lagunitas Brewing Co. was using the EcoVolt to cut its water footprint by 40 percent last year.

Colorado is definitely known for beer (and hence brewing wastewater), so some smart folks at the University of Colorado Boulder saw an opportunity to capture energy and clean brewing wastewater at the same time. The university’s engineers developed an innovative bio-manufacturing process that uses a biological organism cultivated in brewery wastewater to create the carbon-based materials needed to make energy storage cells. The findings were published recently in the American Chemical Society journal Applied Materials & Interfaces.

From an article on the university website:

“Breweries use about seven barrels of water for every barrel of beer produced,” said Tyler Huggins, a graduate student in CU Boulder’s Department of Civil, Environmental and Architectural Engineering and lead author of the new study. “And they can’t just dump it into the sewer because it requires extra filtration.”

Naturally-occurring biomass is obviously an interesting energy opportunity for power makers, and breweries create a lot of unwanted biomass. The CU Boulder researchers concentrated on cultivating a fast-growing fungus, Neurospora crassa, in the sugar-rich wastewater produced by Colorado breweries. From the article:

By cultivating their feedstock in wastewater, the researchers were able to better dictate the fungus’s chemical and physical processes from the start. They thereby created one of the most efficient naturally derived lithium-ion battery electrodes known to date while cleaning the wastewater in the process.

How viable is this research? Well, Huggins and study co-author Justin Whiteley, also of CU Boulder, have already filed a patent on the process and created Emergy, a Boulder-based company aimed at commercializing the technology. The researchers have even partnered with Avery Brewing Co. in Boulder in order to explore a larger pilot program for the technology. As your brewery grows, your wastewater will grow, so it’s important to explore and keep up to date on green technologies like this. Craft Credo No. 5: Support the environment and become energy efficient.

.

Elizabeth Wonder liked this on Facebook.

Lee David liked this on Facebook.

University of Colorado Boulder designs natural battery electrodes from beer wastewater https://t.co/JbYBnyMiCM via @craftbrewingbiz

RT @CraftBrewingBiz: Turn waste into energy: @CUBoulder designs battery from brewing wastewater. #CheersToThat https://t.co/NA22Z6Mn9J