Oregon BEST has awarded a commercialization grant to a start-up company launched by a pair of Oregon State University (OSU) researchers teaming with one of Oregon’s largest beer breweries to test a microbial fuel cell that could help the brewery simultaneously clean its wastewater, generate electricity and reduce the amount of water it sends to the city for treatment. The project seems an ideal fit for a state that is a mecca for craft beer brewing, promotes renewable energy use and prides itself on clean water.

The startup, Waste2Watergy, is partnering with Widmer Brothers Brewing in Portland because brewing is a water-intensive industry, its wastewater contains an optimal mix of organic ingredients for the microbes in the fuel cell and the company pays a significant amount of money annually to the City of Portland to treat its wastewater.

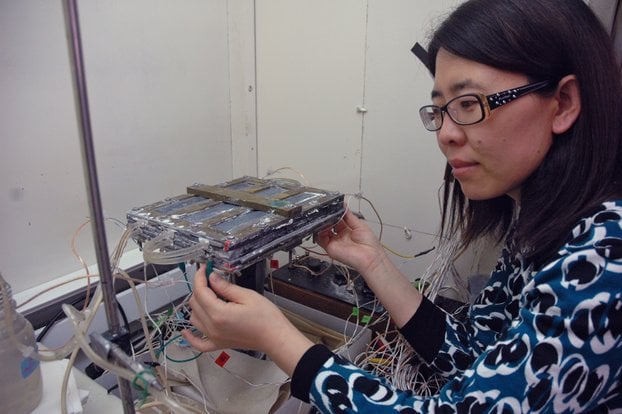

“We chose to partner with Widmer because they are very engaged in sustainability efforts, their wastewater has an ideal mix of organic materials for our technology and they use a lot of water,” said Hong Liu, a professor in the OSU Dept. of Biological and Ecological Engineering, who cofounded Waste2Watergy with Yanzhen Fan, a researcher in the same department. “Ultimately, we want to be able to reuse the treated water after it flows through the fuel cell instead of sending it to the city for treatment.”

The patented technology uses electrodes impregnated with a proprietary combination of microbes that generate electricity when consuming organic matter suspended in wastewater. The process lowers the wastewater’s biological oxygen demand (BOD) level, or the amount of oxygen required by aerobic microorganisms to decompose organic matter in water. Water treatment facilities, including the City of Portland, often charge companies for treatment based on the BOD levels of wastewater.

“We’re very excited about this partnership,” said Julia Person, sustainability coordinator at Widmer Brothers. “In the brewing industry, one of the main measuring sticks is the Water Usage Ratio, or how much water is needed to make a gallon of beer. If this technology can help us reduce our water usage ratio by cleaning our wastewater so we can reuse it, and in the process generate some electricity, it will be a real win.”

Brewing beer uses a lot of water, most of it during cleanup and rinsing operations when residual organic compounds from yeast, grains and hops are washed down drains to municipal treatment facilities that clean the wastewater. The average water usage ratio for the brewing industry is 6 to 8 gal of water to produce a gallon of beer. Although Widmer Brothers’ water usage ratio is about half the industry average (4.2 gal), the facility uses some four million gallons of water per month, paying the City of Portland to treat this wastewater. Widmer’s parent company also operates the Red Hook Brewery in Seattle and Kona Brewery in Hawaii, where they could apply the technology if the pilot proves successful. The $150,000 commercialization grant from Oregon BEST will help Waste2Watergy install a small-scale, a 1-cu meter fuel cell at Widmer’s Portland brewery, where it is expected to treat about 1,000 gal a day while generating electricity.

Liu and Fan have been developing the technology for several years in an OSU lab, but this will be their first pilot project in the field. With help from Widmer Brothers, they hope to prove their technology performs in a scaled-up size in a real-world application.

“If this can be fully scaled up, and we could see an 80 percent reduction in the BOD level of our wastewater, we could potentially see up to $400,000 in reduced costs annually,” Person said.

Liu is confident the cubic meter system will work well and said the company has been great to work with. “At Widmer, they love this concept,” she said. “They have been very helpful, providing us with early evaluations, wastewater samples and a space to install the system.”

The same technology could be deployed in developing countries to treat wastewater while providing enough electricity for lighting or changing mobile devices. Liu has also fielded interest from other large food and beverage companies. The grant is part of $1 million in Commercialization Grants that Oregon BEST has awarded during the past 18 months to speed commercialization of the state’s most promising clean technologies being developed by university researchers and private businesses.

“This is another project that demonstrates the breadth and depth of Oregon’s innovation power in the cleantech sector,” said David Kenney, president and executive director of Oregon BEST. “Enabling reuse of industrial wastewater is an important part of addressing worldwide water quantity and quality challenges, and to attain electricity generation to that adds even more value. So we’re pleased our Commercialization Program is helping this team develop such a unique product.”

Hong and Fan were previously awarded a $50,000 I-Corps grant from the National Science Foundation to participate in an intensive training program for academic researchers who want to commercialize their research. One of 23 teams from across the nation, Waste2Watergy was honored with the best team award at the completion of the six-week training. Waste2Watergy worked with Oregon BEST’s entrepreneur-in-residence Karl Mundorff, who helped coach the team during the I-Corps training and encouraged them to apply for an Oregon BEST Commercialization Grant.

RT @CraftBrewingBiz: Oregon BEST funds OSU-developed microbial fuel cell at Widmer Brothers Brewing @Widmer_Brothers http://t.co/C13sVHwWd9

RT @CraftBrewingBiz: Oregon BEST funds OSU-developed microbial fuel cell at Widmer Brothers Brewing @Widmer_Brothers http://t.co/C13sVHwWd9