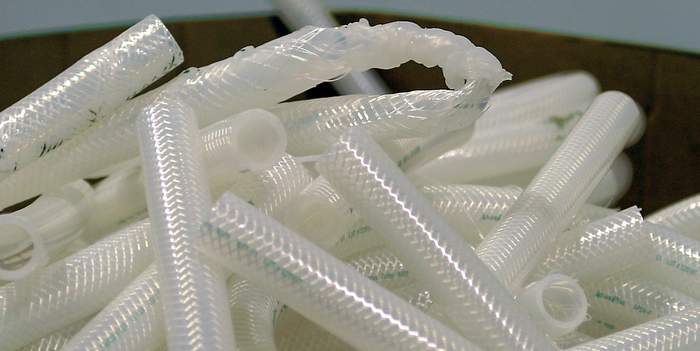

A new style of reinforced hose has been added to the new BrewSavor product line from NewAge Industries. The butyl-lined, monofilament hose is designed to resist kinking and crushing, allowing it to maintain its shape for optimal fluid flow in brewery transfer applications.

“Brewery operations can be fast paced, and hoses can get run over by forklifts or caught between machinery,” said Joe Linquist, NewAge’s Craft Brew Specialist. “This hose is built to return to and maintain its original shape. A hose that won’t remain crushed means a longer hose service life for the brewery and a better return on their process equipment investment.”

BrewSavor, a brand recently established by employee-owned NewAge Industries, aims to provide brewers with application-specific beer transfer solutions. The team is dedicated to manufacturing innovative fluid transfer tubing and hose that exceeds the expectations of both craft and home brewers.

The crush-resistant, reinforced brewery hose is available assembled and ready to ship in standard lengths of 10, 25 and 50 ft. Non-stock lengths are available on request. NewAge produces hose assemblies in-house with knowledge learned from the high purity pharmaceutical industry. The company’s crimping technology results in smooth hose-to-fitting transitions for unrestricted flow and fewer places for beer spoilers to hide.

Features of the new hose include:

- Ultra smooth, white, chlorobutyl rubber liner for purity and unrestricted flow; minimizes bacterial entrapment and flavor contamination

- Multi-layered and reinforced with a monofilament polymer helix for suction and discharge applications

- Rated for full vacuum (29.9 in./Hg.)

- General temperature range: -40°F to 240°F

- Meets FDA, USDA and Canadian Food Inspection Agency (file: N267) standards

- Butyl compound used conforms to 3-A Sanitary Standards for #18-03

- Free of PVC, phthalates and animal-derived ingredients

- Handles Clean-In-Place (CIP) processes

Leave a Reply

You must be logged in to post a comment.