With the growing popularity of craft beers, microbreweries and products made with all-natural ingredients, operations need to be as efficient as possible to keep up with the competition. Whether you’re producing beer or cider, one of the most vital pieces of equipment for increasing efficiency is a heat exchanger. So, before we crack open a cold one, let’s discuss the brewing process, the challenges it poses, and how heat exchangers help brewers tackle those challenges.

Benefits of heat exchangers during production

Thermal treatments are a necessity when producing any beverage that will be bottled, and beer and cider are no exception. Plate-type heat exchangers provide many of these treatments, including cooling, pasteurization, fermentation and aging. When brew and cider houses are just starting out, they may not need or be able to afford a heat exchanger, but once an operation is established, having one is all but a necessity.

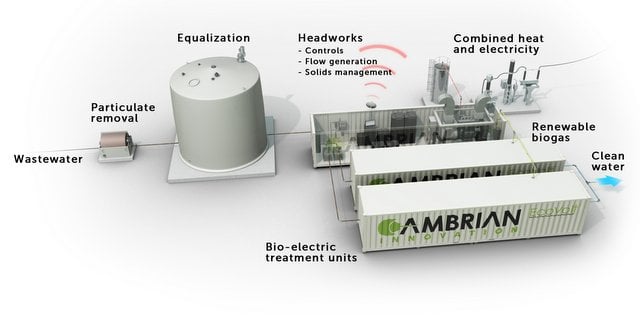

One of the biggest benefits a heat exchanger can provide is a decrease in energy usage and emissions, both of which benefit the brewing process and the environment. A quality heat exchange system also cuts down on the amount of water during the brewing and tank cleaning procedures.

For beer lovers and brewers alike, perhaps the most important advantage of using a heat exchanger is that less beer is lost. In fact, a high-quality system like an Alfa Laval decanter not only recovers more wort and increases the amount of beer that can be made, the savings it provides are often enough for it to pay for itself within two years. All of these benefits lead to a massive growth in production and make breweries and cider houses more efficient than would otherwise be possible.

Here are some of the key ways heat exchangers can help the brewing process.

Beer production basics

The brewing process begins by steeping malted barley in hot water to get the barley to break down into sugars. After an hour, the liquid turns into wort and is boiled in a kettle for an hour or more (depending on the flavor you’re aiming for). This is when a heat exchanger steps into the picture.

Once the liquid has been made into wort, it needs to be cooled down as fast as possible. Lowering the temperature of wort as quickly as possible is crucial in the brewing process, and the bigger an operation is, the more difficult this process becomes. This can be done in a number of ways, including adding ice to the kettle, putting the kettle in ice, and using either a wort chiller or heat exchanger.

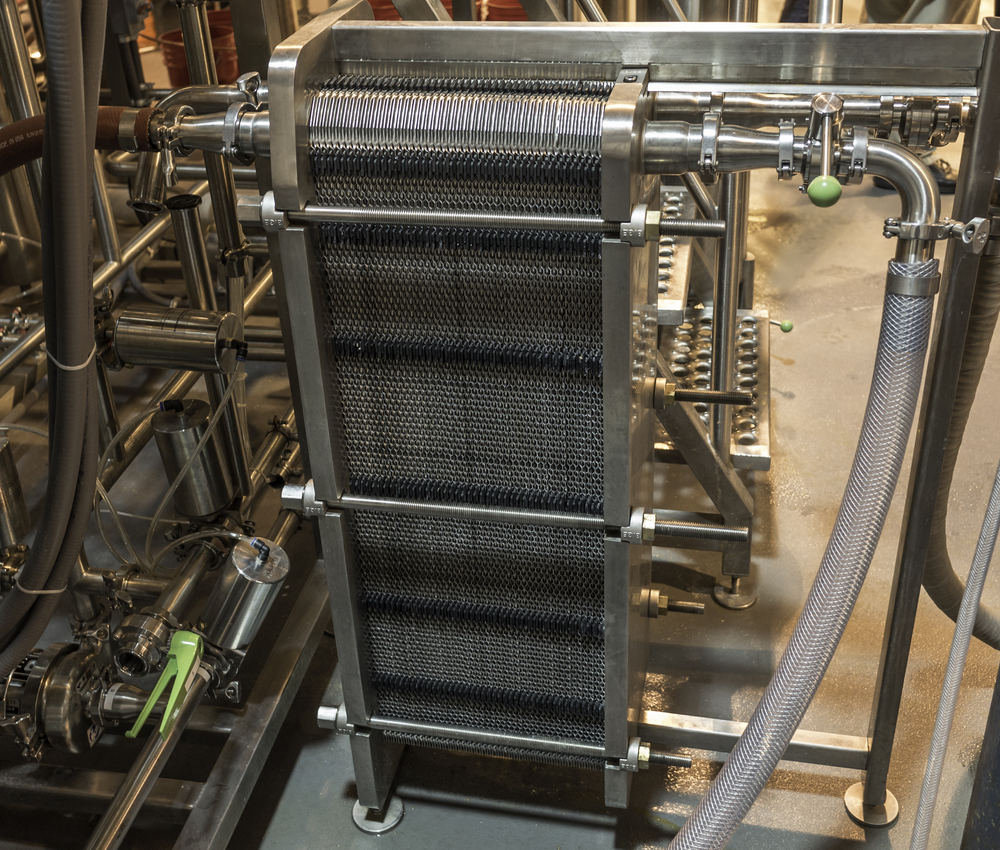

The heat exchangers most often used in breweries are plate heat exchangers, which consist of a series of plates. As a hot liquid flows along one side of the plate, a cold liquid flows along the other side of the plate, producing a “heat exchange” across the plates.

In the brewhouse, hot wort is run through a heat exchanger and cooled by the water or refrigerant running along the reverse side of the plate in the opposite direction. A properly sized heat exchanger can get the right temperature in less than an hour. Once the wort cools sufficiently, it is ready for fermentation.

The cold water then gets heated and returned to a hot water tank to be used for the next brew or for some other purpose in the brewery. The heat used to bring the wort to a boil can be reused to heat cold water entering the building. If a plate heat exchanger uses refrigerants, it can also be used after fermentation to lower the beer’s temperature and allow the aging process to take place.

Cider production

While heat exchangers can be used in much the same way during cider production, the presence of these devices is most felt during the pasteurization process. Pasteurization is one of the most important steps in the production of many bottled beverages, and it is akin to the canning process that people use to preserve juice through the non-growing seasons. There are a couple different ways to go about the pasteurization process — regular pasteurization and flash pasteurization.

Flash pasteurization, which can be used during beer production as well, is catching on and involves heating the liquid only enough to kill certain organisms before cooling it rapidly. This method is used to prevent the pasteurization process from degrading the cider.

Conclusion

Heat exchangers increase production, reduce energy consumption and emissions, allow for less operational water use and assist in wort recovery. While plate heat exchangers are typically used in beer and cider production, it’s not unheard of for shell and tube heat exchangers to be used as well. Either way, there’s no doubt that heat exchangers are indispensable tools to make beer and cider making more efficient, leaving those who make it more time to enjoy the fruits of their labor.

David Holland is the vice president of Mahan’s Thermal Products. Holland has a degree in mechanical engineering which has helped him acquire an extensive background in general contracting and mechanical contracting. He also has extensive experience in the design and construction of mechanical systems and controls. He is also a factory certified as an authorized service provider for Alfa Laval, including designing, repairing and re-rating plate and frame heat exchangers.

Leave a Reply

You must be logged in to post a comment.