Every brewhouse should be a palace of production, safety and innovation. The brewhouse is the heart and engine of your brewing business, and its many complex systems and operations (from mills and mashing tuns to kettles and fermenting tanks) require constant vigilance, maintenance and safety. The journey to the perfect brewhouse and brew crew is a long road rife with big decisions. What’s the size of your system, space available, desired flavor impacts, heating time and, of course, ease of cleanliness using the right chemicals at the right frequency? There are so many questions. What will be the heating source for your kettle or hot liquor tank, or do you have a Lock Out, Tag Out Program to help workers avoid getting hurt when machinery is being serviced?

We decided to tap the big brains of top craft brewers and top brewhouse manufacturers and suppliers (folks like GEA Brewery Systems and Gordon Biersch Brewing Co.) to help sort some of this out. We asked them to share their advice on any topic involving the brewhouse, and the nuggets of wisdom below are the result. We raise a big pint of thanks to everyone who participated. Drum roll, please.

Do your homework

Mitch Steele, brewmaster

Stone Brewing Co., (Escondido, Calif.)

When selecting a brewhouse, it’s important to do some homework and understand what size beers you will be brewing and how much [or how often] you want to brew. Most of the suppliers out there can help with this, but it’s good to crunch the numbers yourself.

For example, many high-quality brewhouse suppliers are from Germany, and they design their brewhouses to brew German-style lagers. Higher gravity brews and high hop usage like what we have in the United States are not things they always factor into their equations. Make sure you calculate your lauter tun loading, proposed grain bed depths for the range of beers you want to brew and also whether you want to brew 24/7. All those things will factor into the size of the brewhouse you need.

A second tip is to visit a few breweries that are operating the equipment you are considering and talk to them about the project management process and the commissioning process. Most brewers are happy to candidly share their experience. Were the suppliers easy to work with? Were they on time? How much support was provided during commissioning? In the end, much of the brewhouse selection process will be highly dependent on your comfort level with the supplier. The opinions and experiences of brewers who have worked with the suppliers can help you develop a decision.

After you calculate the size brewhouse you need, increase it by 50 percent. Just about every brewer out there over the last few years has underestimated growth. More quickly than they imagine, they are out of brewhouse capacity and either have to expand or build a new facility.

Operating a brewhouse: My biggest tip is to make sure you identify critical spare parts and keep them on hand, especially those with long lead times. Work with your supplier and maintenance teams to develop an effective preventive maintenance program that includes proactive replacement of valves, lauter tun plow blades, etc. Another tip is to get into the routine of auditing your brewhouse process. Track a beer you brew often from start to finish, make notes on how the mash and wort move through the brewing process, and then recheck this periodically to make sure things are still working consistently. Measure details such as first-wort gravity, final runnings gravity, and evaporation during the boil, and strive to make these consistent from batch to batch.

Understand the Basics

Udo Funk, sales director of North America

Ziemann USA Inc.

Size: What is the final production capacity you want to achieve with the new brewhouse and what is your projected growth rate? Do you (initially) want to work in two shifts? Brewhouse capacity is determined by batch size and number of brews per 24 hours. Modern brewhouse equipment can produce up to 12 brews per day, even with the strong craft brewer beers.

Flexibility: Look for expandability of the system. What is the desired degree of automation? Can you easily add and integrate new process vessels in the future? Is the brewhouse able to grow with your sales? Take into account alternative technologies, e.g. lauter tun vs. mash filter.

Yield: The craft brewer market is growing and is getting increasingly competitive. Raw materials are getting more expensive. In a couple of years it will be difficult — even for small breweries — to run a successful business with a brewhouse that produces 20 percent losses when you brew an IPA.

Guarantees: Here the most important of all advices: Make sure you get guarantees for yield and brewhouse production capacity and make sure your contract makes them enforceable.

What is best for your beer?

Dean Coffey, co-founder and brewmaster

Ale Asylum (Madison, Wis.)

In 2012, we underwent a large expansion that entailed a total build out of our entire brewery operation. While in the planning stages of our brewhouse, I was approached by manufacturers from all over the world. After very little deliberation, I chose to work with W.M. Sprinkman Corp. in our home state of Wisconsin. Not only did we support a local-owned business, but they custom-made quality and state of the art equipment that perfectly suited our needs. Two other factors played in my decision making while designing our brewhouse: What is best for the beer, and how can we be more sustainable? Years ago, I heard about a vessel that would volatilize DMS that builds up during whirlpool. I approached the engineers at Sprinkman and asked if they could come up with something like this. They added a fifth vessel to our brewhouse that strips out DMS right before the wort is transferred to fermentation. Our nickname for this fifth vessel is our stripper. The first time we brewed on our new brewhouse I climbed up on the roof, walked over the stack connected to the stripper, and sure enough: I could smell creamed corn wafting out! The most sustainable practice we have in our brewhouse is the use of a calandria. Most breweries will use either direct flame or a steam jacket for heating the wort in the brew kettle. Our calandria contains 26 one-inch tubes that bring the wort to a boil. Although this method costs a little more to install, it makes us 85 percent more energy efficient, reducing our carbon footprint. My freedom in brewhouse design was a lot different when we opened as a startup brewery in 2006. Over time, I formulated a wish list and made small changes that grew more impactful overtime. No matter what your brewery size is, doing research and methodical thinking will ensure that you have a system that best suits your needs.

Brewery output and system selection

Gregg Norris, sales engineer

GEA Brewery Systems (Columbia, Md.)

When searching for a brewery equipment supplier, the brewer needs to take a comprehensive look at their own needs before choosing the brewing solution provider that suits them best. A brewer’s expected sales coupled with their project budget will likely determine the next brewing system that they purchase. Nanobrewers, pub brewers and very small production breweries rarely require high yielding automated equipment. The cost incurred simply will never be made up by the production efficiency savings these systems offer. Only if money is no object, and quality considerations are paramount, will a sophisticated brewhouse be the right selection for this individual.

Growing brewers approaching 10,000 barrels per year should consider an “engineered” brewhouse that offers high extract yields and superior throughput. Brewers producing 10,000 to 30,000 barrels per year need to weigh capital cost vs total cost of ownership [TCO]. Is the reliability and repeatability of an automated, well-engineered, brewhouse important enough to wait on the ROI that may take 5 to 10 years? That is the question these midsized brewers must ask.

Brewers making more than 30,000 barrels per year will benefit profoundly by investing in high-end, ultra-efficient brewing equipment. This is why the GEA Compact-Star is a great choice for the growing craft brewer. The Compact-Star program is modular. By starting with just the brewhouse you need, and then easily increasing capacity as you grow by adding vessel modules, up-front costs can be reduced. The system includes GEA Lauterstar technology, making high extract yields of 97 to 98 percent a common result. Simply put, less malt is required to make the same amount of beer, which means more money in the brewer’s pocket. And the GEA Jetstar wort boiling system is gentle, effective and extremely energy efficient. These factors alone will return investment dollars very quickly and, in view of that, a high-end, ultra-efficient brewhouse should be at the top of the list for anyone making more than 30,000 bbls a year.

Develop your repair team

Dan Gordon, co-founder and director of brewing operations

Gordon Biersch Brewing Co. (San Jose, Calif.)

Preventive maintenance is the key to keeping the brewhouse going. There are a ton of moving parts and any one of them can go south at any time. You do yourself, your business and your wallet a great service in the long run by minimizing the risk of equipment failure.

Keep all moving parts lubed up and inspect everything on a regular schedule — that means keeping a calendar. Replace gaskets and bearings before they produce leaks or sounds that indicate future issues. Keep that calendar going on every part that is susceptible to wear and tear. Any items that are hard to find or replace should have a twin in your equipment room ready to go in a moment’s notice. Make sure the corresponding fittings are in place to make the swap as quick and efficient as possible. If it’s an expensive part, ask the brewhouse manufacturer to keep a back-up in their inventory so you can have it overnighted to you if necessary.

Your team for repairs is among your most important assets. At Gordon Biersch, we’ve always maintained that a mechanic and electrician can learn about brewing a lot faster than a brewer can learn to become a mechanic or an electrician. It’s so important to have the talent in-house to keep the brewery operating. Talent isn’t cheap, but major equipment failures can put a brewery out of business.

First priority should be a control electrician. This person should know everything there is to know about motor starters, frequency controllers, sensors, PLCs and control panels. You won’t be pulling wires in the brewery, so don’t go looking for a construction-type guy. That’s important to remember because if you hire the wrong kind of electrician, you’ll be paying for a skill set you don’t necessarily need. Your mechanic should be able to remove, rebuild and install just about every moving part in the brewery without having to think about it.

The perils of improper sanitation

Dana Johnson, VP and BOG representative for the Rocky Mountain district

Birko (Henderson, Colo.)

Because of the amount of heat used in wort production, brewhouse sanitation is often not given as much importance as fermentation vessels, brite tanks and packaging equipment. This oversight can be short-sighted and end up causing problems with the equipment and the beer down the road. Let’s take a look at a couple of areas where improper brewhouse sanitation can harm the equipment, finished beer and the bottom line.

- Mashtun screens

- Kettle

- Whirlpool

- Heat exchanger

Mashtun screens are often overlooked because they oftentimes can have protein deposits that are not removed in normal cleaning from the bottom of the screen. Soiled equipment can cause off-flavors in the beer. Kettle deposits can impede the heat transfer, which takes more energy to boil the wort. Whirlpools can become soiled and harbor organisms if not properly cleaned. Heat exchangers are typically the first piece of equipment to investigate when wort spoilers become an issue. Remember — great tasting beer begins with maintaining proper brewhouse sanitation. Birko manufactures a full line of cleaning and sanitizing chemicals that help brewers keep brewhouse equipment in pristine condition, batch after batch!

Safety first in the lauter tun

Tyler Glaze, quality manager

Short’s Brewing Co. (Elk Rapids, Mich.)

Are you operating an older lautering vessel? Are you climbing in there and pulling the screens regularly to clean them? Are you practicing lockout and confined space procedures?

Cleaning a lautering vessel on a older brewhouse means getting in there and getting your hands dirty when pulling those screens out — and when you’re inside the vessel, you are exposed to a large number of hazards. Locking out the power and wedging the rakes so they cannot and will not rotate is essential. But this isn’t the only hazard present. The liquid and mash transfer lines should be locked out as well to make it impossible to engulf an entrant. Providing ventilation to the space is also necessary to ensure not only a cool environment but also to eliminate the possibility of having hazardous gases present. The entrant should be wearing a properly calibrated and functioning confined space gas meter like a Draeger X-AM 5000 with the appropriate sensors. Finally, you should keep great records of these procedures. Every operation is different, so there may be more hazards present that aren’t listed here.

Specify piping

Barry Campbell, vice president of advertising and media relations

Aquatherm (Medina, Ohio)

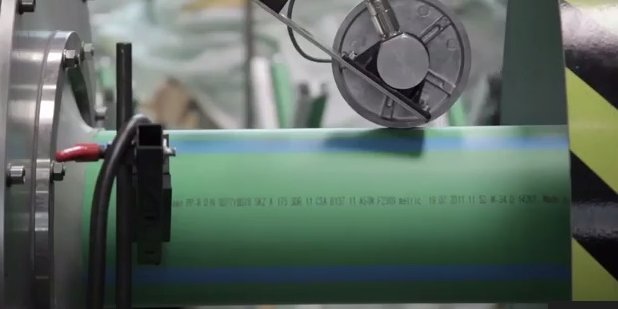

All too often the piping systems transporting domestic water, heating/cooling fluids, process water and other waste are more of an afterthought for those designing and operating breweries. Piping systems play an essential role in delivering pure water, chiller water/glycol and building necessities such as heating and cooling water. Many craft brewers across the United States and Canada have discovered that specifying a single pipe system for the majority of their needs can save on labor and material costs while simplifying the construction and maintenance process. Connected by heat fusion, a process so reliable it is used in natural gas systems, polypropylene pipe systems have been delivering outstanding results in the craft brewing world.

For example, polypropylene delivers chiller water for breweries such as Epic Brewing Co., Big Sky Brewing Co., Aardwolf Brewery Co., Eventide Brewing, Veteran’s United Craft Brewery, Main Street Brewing Co. and others. The benefits of using polypropylene piping systems, which are virtually leak-free since they’re connected by heat fusion, chemically inert, corrosion and scale-free, possess a natural R-value and more, have prompted several breweries to expand their usage well beyond glycol. For example, Founders Brewing Co. used a polypropylene pipe for its heat recovery system and Arbor Brewing Co. used it for its radiant cooling and domestic water supply.

When it comes to specifying pipe for a microbrewery, consider the lifecycle of the piping system, what sort of maintenance will be required to keep it running at maximum efficiency, first cost, labor installation savings, expandability and, of course, operating temperatures relative to leak mitigation.

Remember to re-use grain

Robert “Wob” Wanhatalo, brewer

The Mitten Brewing Co. (Grand Rapids, Mich.)

Though you may not give it much thought in the planning process, removal of the grain husks left over from mashing is a serious and ongoing issue that startup breweries should be mindful of. Shortly after we opened, we were fortunate to find a local farmer who was interested in using our grain as a feed additive for his beef cows. He was even willing to come pick it up and cart it away!

Our 3-barrel brewpub uses a shovel, 55-gallon wastebaskets, and a two-wheeled cart to remove grain from the brewhouse. An average brew day will fill two of these, and they are heavy. Make sure you consider the weight of the wet grain before purchasing a flimsy vessel for transporting them. We store these around the back of our facility until they are ready to be picked up. Our 20-barrel production brewhouse produces quite a bit more grain. Our farmer friend keeps a trailer onsite for us. We fill it up after each brew day, and he comes by with a new clean trailer and swaps it out for the full one.

Spent grain has a variety of other agricultural uses. It is regularly used as fertilizer due to its nitrate and sulfate content. In addition to cows, spent grain is often regularly fed to chickens, pigs, sheep and llamas. Recently, we’ve begun to experiment with adding spent grain into our pizza crust for an additional dimension of flavor and texture.

Learn how to buy and maintain a #craftbeer brewhouse from the experts! http://t.co/flNbQ6PJVq @craftbrewingbiz

Andreas Ehinger liked this on Facebook.

The Mitten Brewing Co. liked this on Facebook.

Brian Sievers liked this on Facebook.

Charles Schmidt liked this on Facebook.

Birko’s brewery specialist, Dana Johnson, was a contributor in a recent article in Craft Brewing Business:… http://t.co/G9IsB30OxK

RT @CraftBrewingBiz: How can I buy and maintain a brewhouse? Advice from top craft brewers and equipment mfgs. http://t.co/TmCKY6Yj9X

ICYMI: Wob featured @CraftBrewingBiz about brewhouse maintenance! | http://t.co/2PSPCYOkm4 #craftbeer #brewing http://t.co/uYSlbDOpFG

Alexander Basa liked this on Facebook.

Jordan Wangler liked this on Facebook.

Peter N Kerry DoyGard liked this on Facebook.

Sunny Choi liked this on Facebook.

Jerrod Hays liked this on Facebook.

Alessandro Zekka liked this on Facebook.

Joël Back liked this on Facebook.

Jerry Elliott liked this on Facebook.

Asier Garcia liked this on Facebook.

Rasmus Wille Broge liked this on Facebook.

T. Dustin Hauck liked this on Facebook.

Courtney Spitzer Stevens liked this on Facebook.

Louie Turcotte Jr liked this on Facebook.

Filipe Araujo de Paula liked this on Facebook.

Evan Bonsell liked this on Facebook.

Kangha Ryu liked this on Facebook.

황찬우 liked this on Facebook.

Nicole Riegel Smith liked this on Facebook.

Lee Yunyong liked this on Facebook.

.@CraftBrewingBiz featured @mittenbrewer in their recent article on purchasing and maintaining brewing equipment! | http://t.co/DFNeNVT2b5

Anders Kleinstrup liked this on Facebook.

Enrique Zuleta liked this on Facebook.

Jason Rivera liked this on Facebook.

Slvtr Chrs Trnbn liked this on Facebook.

Shade Tree Beer Brewers liked this on Facebook.

Amanda Pio liked this on Facebook.

Jason Kneupper liked this on Facebook.

Jonathan Turner liked this on Facebook.

RT @CraftBrewingBiz: How can I buy and maintain a brewhouse? Advice from top craft brewers and equipment mfgs. http://t.co/TmCKY6Yj9X