With three breweries and brewpubs along the coast near Portland, Pelican Brewing Company, established in 1996, now produces nearly 50,000 barrels – equivalent to almost six million liters – every year, serving Oregon, Washington, Idaho, and California, and with an eye on further expansion. It makes beer on demand for its retail and consumer customers, a key element of the quality and freshness standards to which it holds itself.

The craft brewer was looking for a software solution that could provide better insights to help it identify and resolve issues, improve efficiency, and reduce waste.

“We had used other software before, but it never had the right levels of automation or any real-time data,” said Martin Bills, Director of Brewing Operations, Pelican Brewing Company. “My ears are well trained – I can tell if there’s an issue on the line, and in time I can figure out the cause.”

This time Bills turned to Australian manufacturing performance software company, OFS, which is making its official debut in the United States with Pelican.

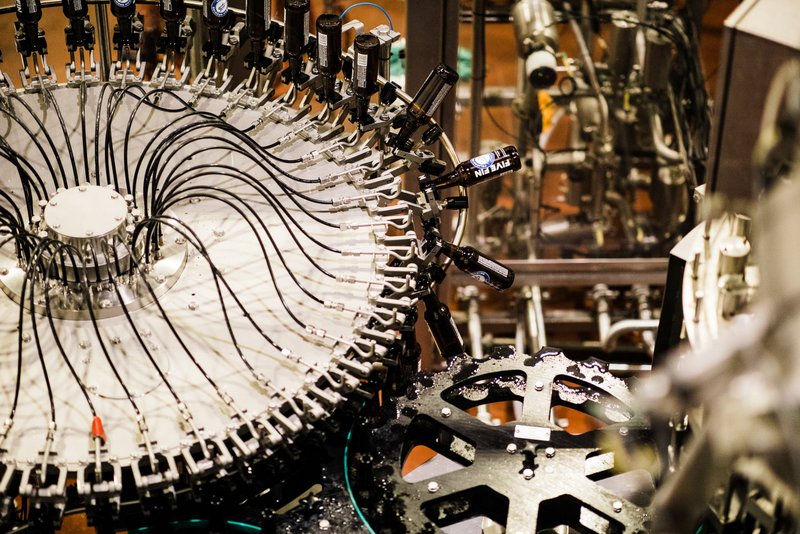

The OFS software uses sensors to draw real-time data from Pelican’s filling and packing lines and combines this with insights from the folks who operate the line to identify and reduce inefficiencies and waste. The implementation of OFS hardware and software at Pelican was completed in less than one day.

One of the key areas where Pelican has seen tremendous value is in starting up production.

Understanding the inefficiencies and inconsistencies in methods and time consumed as operators perform sanitation and initial quality assurance/quality control (QA/QC) checks is very important. Pelican can now identify the delays that occur early in the morning, allowing the team to optimize these processes.

Another significant insight, and subsequent opportunity, discovered during the OFS trial at Pelican Brewing Company came from an unlikely source. OFS identified that the cardboard boxes used on the bottling line wasn’t folding correctly due to quality issues, resulting in one of the biggest causes of unplanned downtime. Pelican was able to use this data to hold the supplier to account by demonstrating with data, the amount of lost time that had stemmed from poor quality product.

OFS also highlighted hundreds of short, approximately one-minute stops at the filler and crowner, which fills and caps beer bottles. As these were minor stops, they had largely gone unnoticed – but the data uncovered by OFS broadcasted the opportunity, the cost, and that the issue or micro-stops needed to be resolved.

Further, OFS identified that one of Pelican’s canning lines had lost almost a day’s worth of production due to running slower than its rated/costed speed. The team identified several key reasons behind this and performed experiments to improve speed, which during the trial phase alone has led to a speed increase of more than 10 per cent.

Data providing the intel to grow

Pelican Brewing Company has its sights set on further expansion, buoyed by the renewed energy in the craft beer industry after the slowdown brought on by the COVID-19 pandemic. Pelican has restarted construction of its new brewpub in Lincoln City Oregon, confirmed to be completed by mid-2022. Pelican remains committed to its ‘brew-on-demand’ model to maintain its quality standards and believes the data OFS unlocks will help it to efficiently expand.

“We’re enjoying much higher visibility across our brewing operations,” said Bills. “Over time, that data can inform our expansion and ensure we’re maximizing our efficiency and reducing waste as we increase output. As a passionate brewer, we simply want to make more exceptional beer for our customers – OFS shows us the right questions to ask and the answers to do that.”

OFS CEO James Magee believes the Australian software provider can become the de facto standard for the US craft brewing industry as it has in Australia. “We conducted an industry report focusing on US and Australian brewers and found that craft brewers typically spend more than half their time not making beer,” said Magee.

“That’s not a desired state for any craft brewer, and at the core of it the issue is data – or a lack of how to measure performance and make the right changes based on it. This ultimately leads to bad days on the brewing packing line, and we’re on a campaign to relegate those days to the past. Pelican understands this link incredibly well and is making the right data decisions for better days and better beer.”

Leave a Reply

You must be logged in to post a comment.