The factors in hops that make or break a beer are lupulin as well as the hop resins (alpha and beta acids) and hop oils it contains. During the boil, the alpha acids transform into iso-alpha acids, which bring out the beer’s bitterness and are used as a gauge of its International Bitterness Units (IBUs).

But hops can do so much more. Very special aromas come from the hop oils extracted from aroma hop varieties. Hop oils are volatile and are lost at excessively high temperatures. That is why aroma hops are not added to the beer wort during boiling. Instead, the hop oils are added during a second step, namely dry hopping. This process of dry hopping, sometimes referred to as “cold hopping,” is mainly associated with craft and specialty beers.

GEA’s HOPSTAR Dry is a slick system for the dynamic cold extraction of hop oils, and Germany’s Störtebeker Craft Brewery was one GEA’s first customers to give it a shot. Early in 2019, the two companies signed a contract to build, install and commission GEA’s system; the work was successfully completed the following August. Now the beers Störtebeker makes with high pellet loads come out even more homogeneous using fully automated, stabilized processes.

“In addition to our love of innovation, we also care deeply about continually enhancing our production processes,” says Jens Reineke, Head of Innovation Management at Störtebeker. When they chose the GEA HOPSTAR Dry, the Störtebeker Craft Brewery got a dynamic system for extracting hop oils that ensures quality and optimizes process times.

Dry hopping efficiency

In classic dry hopping, hop cones or pellets are placed in the storage tank, where they remain until the end of storage. However, this static process hinders extraction efficiency because the hop particles sink to the bottom of the tank, which means they have less contact with the extraction medium, i.e. the beer. With hop pellets, there is also the risk that they may not disintegrate fully.

Removing the hops at the end of the process is especially challenging for brewers and causes substantial beer losses, as the centrifuges used in the subsequent stage are not usually made to handle the high remainder of solids. In the industry, beer losses of 10 to 20% depending on the specific hop dosage are common.

“With the HOPSTAR Dry, GEA has developed a process that significantly improves extraction efficiency – by 30 to 50% compared to a static process,” says Isabel Osterroth, the product manager responsible for fine-tuning the GEA HOPSTAR Dry.

The key is using dynamic extraction in an extraction vessel, where the pellet hops are first fully suspended by a low-shear agitator and kept in motion via pumping. The solids are separated during a sedimentation step, keeping them in the extraction vessel. An additional fine filter catches the finer particles which do not sediment out. This means that only minimal solids are transferred to the cylindrical-conical tank (CCT) and beer losses due to pellet solid sludge are kept to a minimum.

Extraction and sedimentation can be repeated in variable cycles, giving the brewer excellent control in terms of contact time and extracted hop oil fractions. The process is carried out in a CO2 atmosphere to avoid oxidation, which results in a more homogeneous product.

Fully automated plug-and-play unit

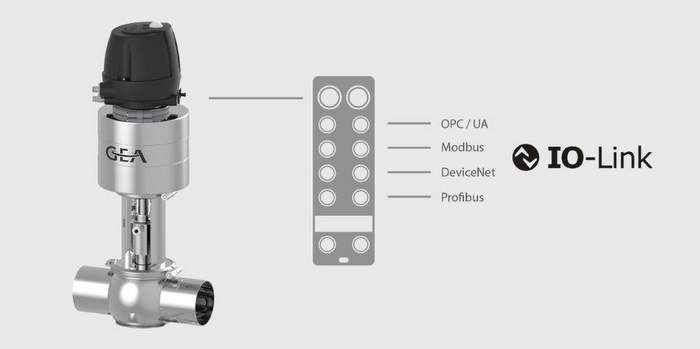

The GEA HOPSTAR Dry is a plug-and-play unit that comes as a pre-piped, tested skid with two pumps and a separate extraction tank. It can be seamlessly integrated into existing systems or set up as a stand-alone unit and connected to the cylindrical storage tanks. One HOPSTAR Dry system can be used for several storage tanks. The skid features its own controls and interfaces to exchange signals with the peripheral installations. As all the steps in the process are automated, product quality is reproducible and clean-in-place (CIP) processes meet the highest quality and hygiene Standards.

Leave a Reply

You must be logged in to post a comment.