Canning was trending as the most popular craft beer packaging option the last few years, but the pandemic kicked interest up a notch as taproom-focused breweries were forced to shift into new sales formats and distribution channels. For craft breweries looking for their first canning line or to upgrade their existing setup, we reached out to manufacturers of equipment up and down the line — from depalletizers and fillers to labelers and multi-packers — to tell us about their top products and specialties.

Canners / Fillers

Twin Monkeys Beverage Systems

Top Tier Canning Systems

Product range: 10 to 100 cpm

Product spotlight: The Cimarron

This system is perfect for: Breweries who are planning for growth.

Key Specs

- Grow from 1-5 fill heads on a single lane, and 5-10 fill heads on a dual lane.

- Cans are weighed post-seam, and if they are below your set weight, they are rejected, then the fill-head that supplied the low fill will auto-adjust until it is within range.

- Water from pre-rinse reused for post rinse, among other eco-friendly features.

Cimarron is our most versatile machine. It’s adaptability allows it to become the exact machine every brewery needs. It’s robust feature set allows for unique customization, and it’s automation always works towards a reliable, repeatable fill and seam that keeps your beer as fresh as it can. The ability to grow the machine from 1-10 Fill-Heads allows for you to grow your business at your own pace and know that the Cimarron will always be prepared to meet your demands, allowing for any number of features to be dialed in. The Cimarron is also built to turn off the power and water when there is a pause in use. Mobile Canning operations, the compact footprint paired with the high can per minute ability and QA features make it a natural choice for mobile canning.

Price: Base Price starts at $67,000

For those who need less, try: Our entry level Mancos system or our 3 Fill-Head Gunnison offer great canning options for entry level and mid-size operations.

For more info: www.twinmonkeys.net

Sales contact: [email protected]

Pneumatic Scale Angelus

Expertise in high speed beverage canning, scaled for the needs of craft brewers.

Product range: Inline canning lines from 15 to 100 cpm; rotary systems up to 250 cpm.

Product spotlight: CB50C Counter-Pressure Integrated Canning Line

This system is perfect for: Meeting the growing consumer demand for hard seltzers, sparkling wines, and high-carbonation beers in a can.

Key Specs

- Integrated inline filler with single-head can seamer, rated for continuous operation at speeds up to 50 CPM

- Six individual filling heads utilizing isobarometric counter-pressure technology and proprietary magnetic flow meter technology, capable of 1 mL precision

- Seaming technology optimized for beverage applications

The Pneumatic Scale Angelus CB50C leverages the same counter-pressure filling technology and industry-leading Angelus seaming technology as in high-speed beverage lines, but is scaled for the needs of the craft beverage industry. Our system uses true isobarometric filling, with the fill tank positioned above the fill heads, allowing the product to be gravity-fed, as opposed to pumped/forced upward. The system also relies on accurate and repeatable fill level metering, using precision magnetic flowmeter technology. Fill cycle parameters are adjustable through an intuitive HMI display.

Price: Price dependent on configuration – contact PSA for a free quote

For brewers wishing to fill lower-carbonation beverages: The CB50 and CB100 inline machines, filling up to 50 and 100 CPM, respectively.

For those looking to expand their production, but retain the flexibility: The CB244 rotary canner, reaching up to 250 CPM.

For more info: https://www.psangelus.com/machines/craft-beverage-integrated-filler-seamer-systems

Sales contact: [email protected]

Wild Goose Filling

Canning & Bottling Systems for Quality Craft Beverages

Product range: Up to 100 cpm

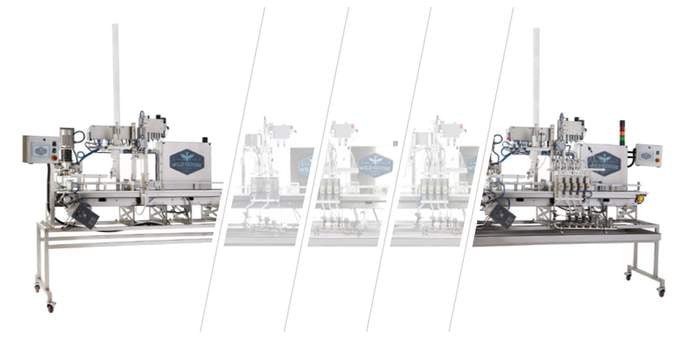

Product spotlight: Evolution Series

This system is perfect for: Breweries who want their canning system to grow with them.

Key Specs

- Cost-efficient growth from 15 up to 50 cpm on the same upgradeable, fully automatic platform

- QuickChange configurations to shift easily between can bodies, heights, lid types or any combination – complete a full changeover of everything in under 35 minutes

- Filling and seaming technologies that deliver repeatability and protect product quality

Wild Goose Filling’s upgradeable Evolution Series canning lines grow as your brewery grows, offering superior precision canning for brewers focused on quality. Modular system options support you as you take the steps from your earliest production stages to higher speed canning, providing the opportunity to grow affordably on your machine from 15 up to 50 cans per minute. Start canning with any system in the 1-through-5-head filler series and upgrade stage by stage or multiple stages at once depending on your demand. Mobile configurations and a full line of ancillary equipment options make the Evolution Series the complete automated packaging solution to meet the unique needs of your growing craft brewery. Backed by Wild Goose’s renowned customer care, the Evolution Series is here to support you and your future growth.

Price: Dependent on configuration

For those who need a bigger system, try: Dual-Lane Evolution Series canning systems up to 100 cpm

For those who need less, try: Gosling small-volume professional canning system, now with Nitro and QuickChange Configurations

For more info: www.WildGooseFilling.com

Sales contact: [email protected]

American Canning Machines

Creating custom canning solutions for craft beverage manufacturers

Product range: 6 to 40 cpm

Product spotlight: 1-head Tabletop Filler/Seamer

This system is perfect for: Small-batch canning of carbonated beverages

Key Specs

- Compact 15”x18” operating footprint (24”x40” with optional rotary infeed table)

- Fills any standard 211 body-diameter can (8oz to 19.2oz) at 6-12 CPM (CPM varies per fill volume)

- Optional rotary infeed table provides 22 cans of simultaneous in-feed/out-feed accumulation

American Canning Machines’ single-head filler/seamer might be the most compact, fully-automated canning system on the market. Designed for small batch canning, this single-head, atmospheric filler runs any standard 211 body-diameter can from 8oz to 19.2oz at 8-12 cans per minute with superior packaging quality and minimal dissolved oxygen pickup. The simple one-page user interface gives operators easy access to everything needed while the optional infeed table allows plenty of queue to avoid pauses in fills. – Pre-purge and underlid gassing mean minimal dissolved oxygen pickup. The Servo-driven seamer gives high power within a compact system. Quick clamp height adjustment to run any fill-volume, standard diameter can. Integrated drain pan and wash down rating.

Price: $19,800 – $23,480

For those who need a bigger system, try: American Canning Machines 4-head Filler Seamer

For more info: americancanning.com/collections/american-canning-machines

Sales contact: [email protected]

Cask Global Canning Solutions

Pioneering, innovative canning systems from the inventors of micro-canning

Product range: Manual and automated systems from 10-100 cpm

Product spotlight: Micro-Automated Canning System (mACS)

This system is perfect for: Craft brewers looking for one affordable, versatile, small-footprint canning system.

Key Specs

- The best foam control and lowest product waste in the industry thanks to Cask’s proprietary filling technology, and food-grade stainless steel fill heads to allow stronger sanitizing/CIP that won’t leave any flavors or beverage residue behind.

- Premium automation and technology in a compact, easy to run system (requires just 1 operator) that produces 25 cans/min.

- Ultimate small-scale system for nearly every can size (height and width) and beverage type.

The mACS features the automation, fill tech and seaming reliability of Cask’s larger Automated Canning System (ACS V5), in a small, mobile and affordable system. For brewers seeking package and product flexibility, it fills a wide range of can sizes with easy changeover in just 30 minutes. A conveyor belt can feeder allows for automated pre- and post-packaging components (depalletizer, in-line date coder, nitrogen doser, pressure-sensitive labeler and others), all in 17.5 sq. ft. system that delivers dissolved oxygen pickup of just 15-20 parts per billion and product waste < 1%. Additional brewer-friendly features include electric cam-driven seamers, a post-fill rinser and dryer, and an intuitive touch screen with CIP and recipe-memory features.

Price: Upon request.

For those who need a bigger system, try: The ACS V5, Cask’s larger-scale version of its workhorse, with 40 cans/min.

For those who need less, try: Cask’s entry level, 10 cans/min Manual Canning System (MCS).

For more info: www.cask.com

Sales contact: www.cask.com/contact/

Seam Inspection

OneVision Corporation

Specialists in can seam inspection equipment to aid canners and control double seam quality.

Product spotlight: All-In-One SeamMate Craft Beverage System

This system is perfect for: Any craft beverage operation that cans.

Key Specs

- Includes everything a brewery needs to ensure quality can seams (equipment and software).

- Includes on-site training (1 full day).

- Includes unlimited phone and email support from the OneVision team.

We manufacture, sell, and service our equipment at our headquarters in Westerville, Ohio, which enables us to provide an affordable, high-quality can seam inspection system to food and beverage makers of all sizes. The purchase of a SeamMate System includes on-site installation and training and unmatched support from the OneVision team. Using the SeamMate System to monitor and detect seaming issues gives brewers the confidence that customers will receive the taste they expect from their canned beverage. SeamMate automatically compares double seam measurements to specs, records, and alerts brewers to potential double seam quality issues.

For those who need less, try: The Mini Seam Stripper, which will eliminate the difficult process of removing the coverhook by hand.

For more info: www.CraftBrewQuality.com

Sales contact: [email protected]

Labeling

Tonejet Ltd

Direct-to-can digital decoration systems for necked beverage cans

Product range: Standard product runs 600 dpi print at 60 cans per minute

Product spotlight: Tonejet Cyclone

This system is perfect for: Short run, low cost can decoration for craft brewers and mass customization.

Key Specs

- The same look, feel and surface finish as traditionally printed cans.

- The only plastic-free short run solution (the printed can remains fully recyclable).

- Lower cost per can than sleeves, labels or inkjet.

Tonejet’s Cyclone digital can printing system comprises all the equipment needed to decorate necked beverage cans, including depalletizer, can inspection system, can cleaning and printing units, over-varnish bake oven, repalletizer and all associated can transports and conveyers. It permits the operator to decorate blank cans using any number of different images in any combination, combining production batches with samples and proofs effortlessly, and palletize them ready for filling or shipping. The system is aimed at printing and packaging businesses who serve the craft brewing industry, as well as larger brewers wanting to minimize can decoration costs and lead times.

Price: please contact Tonejet for this information.

For those who need a bigger system: multiple Tonejet printers can be used in parallel to increase throughput or to run multiple can formats at the same time, giving overall throughput of up to 240cpm.

For those who need less, try: Mimaki manufacture a conversion kit which allows their wide format inkjet printers to decorate cylindrical objects. This setup would be manually loaded and unloaded, and relatively low in throughput. Ink consumption per can would be much higher (at least 20x) compared to Tonejet’s electrostatic pigment deposition process, but the capital cost of the equipment is lower.

For more info: www.tonejet.com

Sales contact: Marvin Foreman, [email protected]

Depalletizers and Conveyors

GR-X Manufacturing

Specialist in designing, building depalletizing equipment

Product spotlights

Full-Height ECO Automatic Can Depalletizer (FHC 1000)

GR-X’s full-height automatic can depalletizer (FHC 1000), also known as our “ECO” unit provides a steady stream of empty cans to maximize your filling operation. This unit was designed specifically for those in the craft spirits industry looking for an economical and automated solution for depalletizing their cans. Discharge/Decline options allow for unloading speeds of 80-150 cpm. The unit is robustly constructed, utilizes quality components, and is designed with easy operation, reliable performance, and a compact footprint in mind. The FHC 1000 can also be customized with a custom powder-coated frame color and corporate logo.

Full-Height Automatic Depalletizer (FHA 3000)

If you require faster speeds, the FHA 3000 design supports flexible configurations, allowing it to be tailored to customer-specific requirements. It’s designed to be able to handle around the clock unloading of your aluminum cans. Discharge and decline options available on this unit allow for unloading speeds of 150-300+ cpm. Roller conveyor, platform, and pallet stacking options can all be added to this unit to meet your production requirements. This depalletizer can also be customized with a custom powder-coat frame color and corporate logo.

For more information: grxmfg.com/depalletizers

Sales contact: [email protected]

Multi-Conveyor

You craft beer … we craft conveyors.

Product range: Conveyors run at your speed requirements.

Product spotlight: Success Line

This system is perfect for: Everyday beer production, 24/7, moving your crafted product reliably through the entire brewing process.

Key Specs

- Pre-engineered for quick delivery

- You choose lengths, widths, curves, transfers, stainless or mild steel construction

- Add custom controls, VFD’s, and more.

We understand the beating that your packaging line can take, day in and day out so we built a simple yet reliable conveyor system designed to hold up. With miles of successful beverage conveyors under out belts we can help you select the right conveyor to work in your brewery – no matter how big or how small.

Price: Custom quoted.

For those who need a bigger system, try: Multi-Conveyor can work with you and your other equipment and integration vendors to design a full packaging line. Important considerations like throughout and accumulation are considered.

For those who need less, try: Hand-pack and rotary conveyors are perfect for 6-pack carriers and manual to semi-automated production.

For more info: https://www.multi-conveyor.com/packaging-solutions/beer-conveyors-craft-brew-and-more

Sales contact: [email protected]

Ska Fabricating

Packaging line automation for craft businesses

Product range: 10 cpm to 600 cpm

Product spotlight: Can-i-Bus Depalletizer

This system is perfect for: Depalletizing cans and other metal containers on packaging lines running from 25-400 cpm.

Key Specs

- Minimal air consumption (<1 CFM @ 20 PSI) (<.03cmm @ 2 Bar)

- Custom configurations available to best fit your space

- Will accommodate full height or smaller pallets

The Ska Fabricating Can Depalletizer is a small footprint, semi-automated depalletizer. It is a heavy-duty machine available in custom heights and designed for canners or breweries with space restrictions. The Can-i-Bus is fully automated once the pallet is inserted and the straps and tier frame are removed, and makes it easy for beverage producers to reduce labor costs while scaling up production. It is a packaging line workhorse that production managers rely on to keep canning days running smoothly with their team spending less time fixing or adjusting poorly made equipment, and more time packaging. We have over 800 CIB’s installed worldwide on lines that run beer, coffee, tea, kombucha, wine, seltzers, CBD beverages, and more.

Price: N/A

For those who need a bigger system, try: The Magic Bus, a fully automated can depalletizer with built-in pallet management capable of speeds up to 600 CPM.

For those who need less, try: The Half Pint, a half-height mobile depalletizer perfect for lines running 10 – 50 CPM.

For more info: www.skafabricating.com

Packers / Carriers

Roberts PolyPro Inc.

Manufacturer of can carriers and related application systems

Product range:

- Manual application to 60 cans per minute

- Semi- automatic running up to 240 can per minute

- Fully automatic running speeds 180 – 1000 cans per minute

Product spotlight: GPA70

This system is perfect for: Multipacking craft beer up to 70 cans per minute creating 4, 6, or 8 pack configurations

Key Specs

- Fully Automatic and in-line with canning system

- Applies the least expensive can carrier in the market

- Runs 4300 six packs or 6450 four packs without downtime

The GPA70 applies Grip-Pak rings, the most cost effective can carrier for 4 & 6 packs designed for 12 & 16 oz cans. The easy removable ring allows total exposure of the can’s graphics without overwhelming the multipack with a bulky presence. The GPA70 is streamlined with your canning system, reducing the extra step of manually applying handles or rings.

Price: $25,000

For those who need a bigger system, try: Our new applicator the GPA1000 will be offered later this year. Speeds are rated up to 1000 cpm.

For those who need less, try: Our Craft-Pak handles and applicators that use 30% less plastic than traditional handles.

For more info: www.robertspolypro.com

Sales contact: [email protected]

Bevco Sales International

40 years of expertise offering packaging solutions to breweries

Product range: Any container size. Up to 1500 cpm (customizable)

Product spotlight: Mix Pack Systems – Stainless Steel Table Infeed

This system is perfect for: Any breweries producing mix packs up to 200 CPM

Key Specs

- Helps to automate the production of mix packs of cans or bottles, Eg. 4 packs, 6 packs, 12 packs

- Integrates into packaging lines with automated cartoners

- Feeds lanes of different flavors into cartoner or tray packer

Assembling multiple flavors of beer into a single carton can be a very labor-intensive process. Bevco’s mix-pack solutions improve the mix-pack production process and ergonomics by feeding laned flavors into the cartoner or tray packer. This table allows workers to manually load different types of product into separate lanes on a conveyor. Stainless steel pack tables are mounted to the side of the conveyor for workers to easily load flats of product and push the containers onto the conveyor belt. Each system is customized to integrate into the customer’s cartoner or tray packer. For breweries who do not have an automated cartoner, there is an optional pack-off table on the conveyor outfeed to manually sweep the containers into a carton. The conveyor lanes can lift up out of the way for bulk container infeed into the cartoner or tray packer. Each system is customized based on customers’ needs and application requirements.

Price: Custom quoted

For those who need a bigger system, try: Mix Pack Systems – Conveyor Infeed (higher speed)

For those who need less, try: Manual hand loading into cartons from pallets

For more info: www.bevco.net

Sales contact: [email protected]

Econocorp Inc.

Get your cans into cartons or trays automatically

Product range: 24 cpm or to 300 cpm

Product spotlight: Twinseal

This system is perfect for: Slow line speeds looking to run a variety of pack patterns and multiple size cans.

Key Specs

- Quick and easy changeover time of less than 15 minutes between pack pattern sizes

- Can handle slim, sleek and standard cans, 8.4 oz to 19.2 oz, in 4 packs to 24 packs

The Econocorp Beer Twinseal machine is a low cost entry point into automating the packaging process of getting your cans of beer in to a cardboard box carrier. It has extremely quick changeover time to go between packaging formats and can sizes and has the capability to handle the largest range in box sizes that the craft beer industry uses. It is also the most simple and economical choice for creating variety flavor 12 packs.

Price: $35,000

For those who need a bigger system, try: E-2000 or Spartan

For more info: www.econocorp.com/industry/craft-beer/

Sales contact: [email protected]

WaveGrip

Sustainable multi-pack solutions

Product spotlight: WaveGrip C80

This system is perfect for: Brewers who want to increase production and begin automation of their packaging lines.

Key Specs

- Up to 80 cpm

- Can change between standard and sleek cans in as little as 15 minutes

- Economical footprint – 20 sq ft

The WaveGrip C80 is an entry-level multi-packing applicator design with craft producers in mind. With a small footprint, low cost, and speeds of up to 80cpm the C80 is the perfect choice for those wishing to enter the market and wish to increase production. The C80 can seamlessly fit onto the end of any production line and in the tightest of spaces ensuring the least disruption to your facility. Like all WaveGrip applicators, our C80 system is built in the USA to the highest standard and backed up by an experienced engineering support team.

Price: N/A

For those who need a bigger system, try: The WaveGrip c400 or c1000+

For more info: https://www.wave-grip.com/carrier-applicators

PakTech

100% recycled and recyclable secondary packaging and automated applicators

Product range: 120 cpm or to 1500 cpm

Product spotlight: PakTech CCA 440

Key Specs

- Capable of processing up to 440 plus cans per minute with a 15% surge rate when needed

- Applies PakTech handles to 12, 16 and 19.2 oz / QuadPak and 6pak

- Allen Bradley CompactLogix PLC, Festo and Parker Hanifin pneumatic components, Banner Engineering sensors

The PakTech Can Carrier Applicator 440 converts from QuadPak to 6pak with a push of a button on the HMI. Height adjustment requires minimal tools and is less than a 5-minute change. Machine is also capable of transitioning between standard cans and sleek cans with the required change parts. A complete switch between these styles of cans is a 30-45 minute change over based on your technicians’ experience. The CCA440 plus HMI comes standard with visual display of your I/O for easier troubleshooting and less reliance on PLC access. The program is ready for downstream and upstream inputs to ensure the machine processes cans when the line is ready or accelerates production to keep other line unit operations running the most efficiently.

Price: N/A

For those who need a bigger system, try: CCA 875

For those who need less, try: CCA 120/180

For more info: www.paktech-opi.com

[…] onsite, has opened up a revenue stream once only reserved for larger breweries. Canning technology has advanced and scaled down to manageable prices so that just about any brewery can afford […]