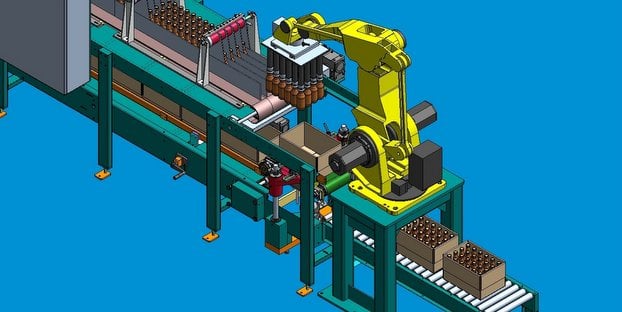

As your craft brewery grows, squeezing every ounce of efficiency out of your beer production is of the utmost importance. It all comes down to the bottomline and keeping up with growing demand. Climax Packaging Machinery‘s Climax CR-25 robotic case packer might just be the automated solution that fits your brewery’s needs. The company explained that it achieves packaging efficiencies through a compact footprint and flexible packing patterns.

Check out the specs:

- Carbon steel construction with a two-part stainless steel epoxy paint primer and finish coat is standard for Climax equipment;

- Permanently lubricated and sealed bearings where available; clustered lubrication fittings where available on other bearings that require lubrication;

- Floor-mounted, expanded metal safety cage with interlocked doors will enclose the robot and product in-feed conveyor system as required for operator safety;

- Product in-feed conveyor with three low friction, plastic flat-top chains or mat top chain;

- Stainless steel, adjustable lane guides for packing up to four lanes wide; and

- Stainless steel drip pan underneath the entire length of the bottle conveyor to contain any product spillage that might take place from damaged or loosely capped bottles.

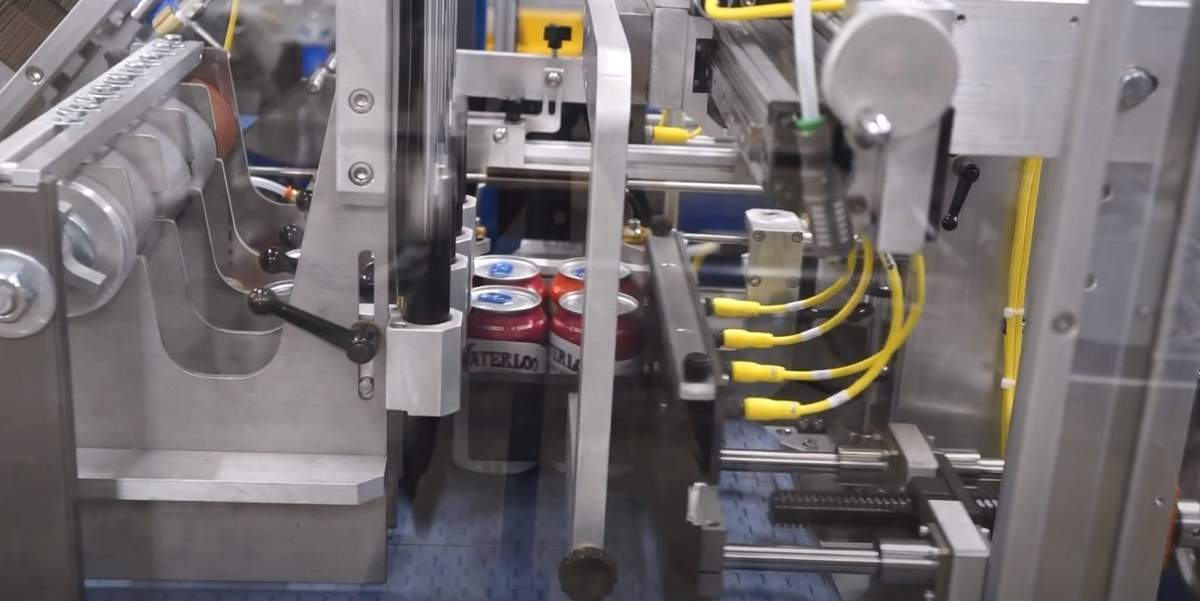

Climax explained that the width between each lane guide is basically determined by the bottle diameter and is established by a series of lock nuts or by the optional quick-adjust lane spacers that are hung across the lane guide support crowns. From there, the bottle stop system halts bottles as they move forward into the robot pick-up zone. Then the bottle stop drops out of the way once the pick-up tooling is seated on the bottles and returns to stopping position once the bottles are clear of the pick-up area. In order to detect the presence of filled cases that have stopped downstream from the Climax packer, a sensor is provided that should be installed on the discharge case conveyor. If cases back up and the sensor is blocked, a signal will be sent back to the packer which will pause the packer’s operation until the sensor is no longer blocked.

The robotic case packer is designed to be as toolless in operation as is possible. For example, hand cranks, twist knobs, hand ratchets and twist-lock handles have been implemented wherever they are feasible without jeopardizing the integrity or operation of the equipment. For more details, head over to the Climax Packaging Machinery website.

RT @CraftBrewingBiz: Climax Packaging Machinery shows off robotic case packers: http://t.co/mmF2xHwGgi @ClimaxPackaging