Since the arrival of the pandemic, the need for high-quality canning at an affordable price has never been more important for craft beverage makers. Cask Global Canning Solutions is now releasing a new system perfect for the times and smaller-scale producers.

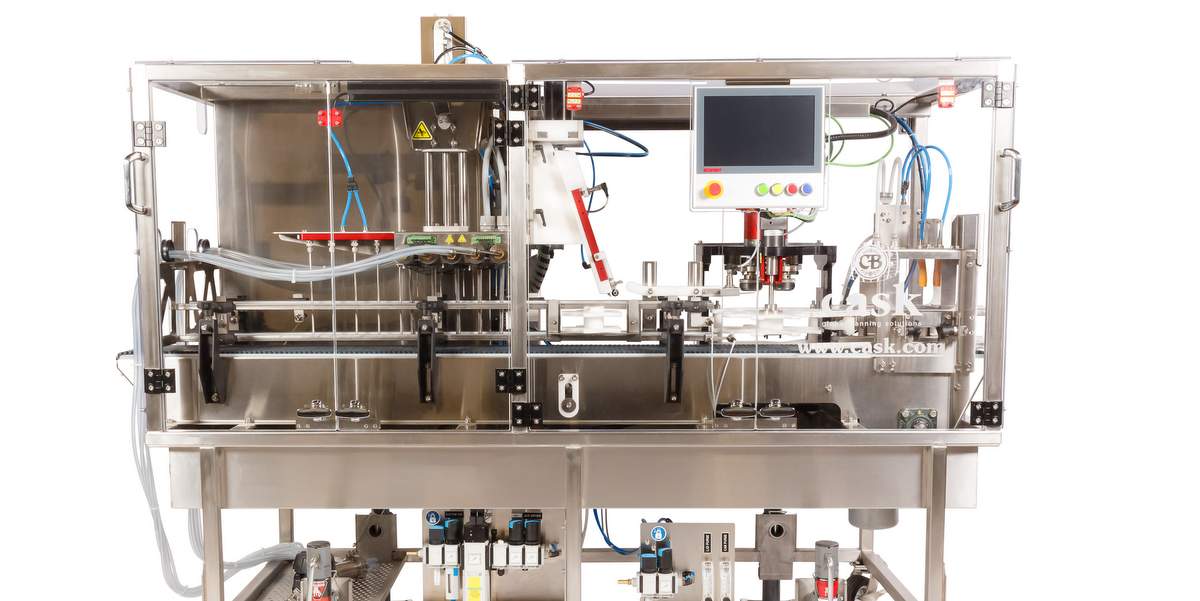

Cask’s new Nano Automated Canning System is the company’s smallest fully automated canning system, and it packages virtually any beverage type and can size in top-quality and affordable fashion. It fills 18 cans per minute and 45 cases per hour, fits in 14 sq ft, and costs about 25 percent less than systems with the Nano’s capabilities and versatility.

“About 85 percent of U.S. breweries,” says Cask president Russell Love, “produce less than 1,500 bbl per year, and they are looking to can their beer or diversify their canned lineup. But we’re seeing many of these producers waste money on canning systems they don’t need. Some think they need expensive counter-pressure fillers to make highly carbonated things like seltzer. But they don’t. All they need is a Nano ACS.”

Ross Alger, owner of Confluence Distillery (Alberta, Canada), can attest to that. “The Nano is great,” he says, “because of its features, price and size. We only need to can a small portion of what we make, a few times each month,” Alger notes. “So it makes no sense for us to dedicate a large amount of our vital dollars and floor space for a larger, overkill system that we don’t need.”

Alger used mobile canning services in the past and was unhappy with their high costs, quality control problems, and large minimum requirements. “By not packaging at the whims of a mobile canner,” Alger says, “we can be much more flexible with our canning volumes and schedule. We can do small canning runs of unique and creative products, and know that they’re properly packaged.”

In addition to delivering extremely low dissolved oxygen, the Nano ACS can package highly carbonated beverages (up to 3.2 volumes of CO2) for those wanting to produce hard seltzers, RTD cocktails, and other high-carbonation beverages. Changeover between beverage types and slim, sleek and standard size cans is fast and simple on the system.

The system’s user-friendly design allows for quick and easy operator training (through a two-day virtual installation), and its automated infeed/outfeed conveyor means the system can be operated by just two people. This fully automated Nano ACS can also be fitted with accessories for date coding, labeling, and nitrogen dosing.

“At every point of its design,” says Russell Love, “the Nano ACS was built for the needs of small breweries, distilleries, wineries, and coffee and kombucha makers. With this system they can produce the highest quality canned beverages, and do so with a right-fit system that helps them succeed and save money.”

Complete specs of the Nano ACS and details of the system’s features and backstory can be viewed at https://www.cask.com/canning-systems/nano-acs/.

Jim Snider says

CANtastic.