In 2014, the members of Together We’re Bitter Co-operative Brewing (TWB) had an idea to bring a quirky craft brewery to the heart of Kitchener, Ontario. There were a lot of considerations, like financing, location and equipment. The team knew they needed to buy an entire brewing system to get this project off the ground. The mystery was, “Where would they find a workable system on their budget?” It’s a mystery that would be solved in a very surprising way.

First the funding. Money came from co-op team member investments and an encouraging Kickstarter campaign that raised more than $16,000. Then the search for the right space shifted into high gear, but location quickly became a challenge. When the first space they imagined didn’t manifest, the group reworked their startup plan and moved forward with an industrial building they found near downtown Kitchener.

RELATED: Crowdfunding craft beer: Viable business strategy or market fad?

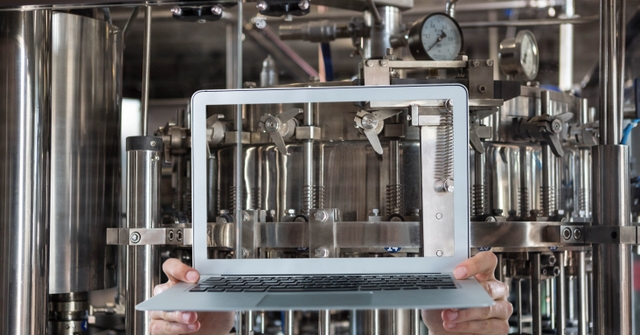

Now the equipment. Two of the co-op member/owners, Rob Shorney and Culum Canally, searched diligently, looking at trade pubs, searching online and reaching out to other breweries. One day Rob got a Tweet from a friend showing a Kijiji ad for a “brewery” sitting in storage up the road in Mississauga. When they arrived at the storage unit, they were pleasantly surprised to find an entire, intact quality brew system. There was a brewhouse, three fermenters, a liquor tank, a grain mill and six tanks that Rob thought were horizontal bright tanks.

“I had never seen this equipment before, and I was worried we were getting antiquated technology. But a little research and we discovered it was just the opposite. The tanks are serving beer tanks and we came to realize they are on the forefront of something revolutionary,” Rob said.

Beer from the tank

The equipment that had been sitting in storage had originally been purchased for a brewery install in Croatia, but somehow ended up in the hands of a father-son team in Mississauga, Canada. The team bought the whole system for a song and moved it back to their warehouse in Kitchener. After months of concepting, pipe fitting and welding, the pieces of the brewing system began to come together. The most unique part of that system were those horizontal tanks which the team discovered were made by Paul Mueller Co. based in Springfield, Mo. And they weren’t just any horizontal tanks, but serving beer tanks that could be used directly in the taproom.

RELATED: Build the ultimate brewhouse using our 2016 equipment buyer’s guide

This wasn’t antiquated technology, but rather it was sitting on the cutting edge. These serving beer tanks with bag inliners are being used all over Europe, and the TWB team would learn they were the first ones to use them in North America. Rob contacted Paul Mueller Co. and spoke with Gregg Shirey, director of business development. Gregg explained that the tanks actually hold high strength bag inliners. It was a self-cooled, bag-in-tank system. Paul Mueller Co. quickly expedited an initial inventory of 1,000 liter bags to TWB. At first, Culum worried the bags would not hold 1,000 liters of liquid under a significant amount of pressure.

“But then I discovered that is exactly what they were designed to do. Not only do the tanks hold the beer at exactly the right temperature, but the inliners eliminate the use of cleaning chemicals and significantly reduce cleaning time and labor,” Culum said.

Together We’re Bitter set aside a large amount of their budget for a cold room and keg storage. With the serving beer tanks and inliner system they found they could practically eliminate the cold room and the kegs. Beer can be precisely temperature-controlled and served directly from the tank.

“Serving beer tanks are the most unique part of our operation,” Rob said. “When other craft brewers come in, it’s the first thing they want to see. They know they are spending a lot of time on kegging, washing kegs and labor, and they could be saving that money by switching to the serving beer tank system.”

Rob said customers also love to see how the taps in the serving room are hooked up directly to the tanks. They perceive their beer being fresher, and it is. It’s one less step from the tank to the pint. The tanks have allowed TWB to start thinking about expansion. The co-op has already begun hiring more workers because of the growth they are experiencing and anticipating.

“The opportunity is tremendous,” Rob said. He is thrilled they found these unique serving tanks in their search for equipment, but Rob says he is even more excited about the partnership they gained with Paul Mueller Co.

“I know serving beer tanks will grow in popularity and won’t be unique to TWB for long, but the personal interaction and partnership we’ve tapped into with Paul Mueller Company is just as valuable. They know the potential and profitability of these tanks for craft brewers around the world.”

Jim Harris liked this on Facebook.

Thanks for the post!

Jim Sung liked this on Facebook.

Serving beer right from the tank at TWB Co-operative Brewing https://t.co/lbH6yWABRW via @craftbrewingbiz

RT @CraftBrewingBiz: Serving beer right from the tank at Together We’re Bitter Co-operative Brewing https://t.co/6qfV8rvMZJ @PaulMuellerCo

#CraftBeer #CraftBrewing #Beer #BeerBiz Case study: Serving beer right from the tank at Together We’re Bitter C… https://t.co/HXXixSgtJt