Acting under the Food Safety Modernization Act, the FDA proposed rules late last year that would shut down brewery-to-farm transfer of spent grain. Meant to protect feed and dairy animals from potential health issues, the rules mandated that breweries take precautions to eliminate contamination from grains that have already been declared fit for human consumption. This unnecessarily stringent requirement would make grain transfer economically impractical.

After considerable push-back from ranchers, farmers and brewing associations, the FDA committed to a reasonable resolution that includes small-scale inspections and a high ceiling-volume under which business will continue as usual. With spent grain management on the radar and a minor crisis averted, Cambrian Innovation is taking an in-depth look at all brewery by-products. Significant economic and environmental value, in the form of clean water and clean energy, lies embedded in the solid and soluble waste from the brewing process.

However, the opportunity to capture this value is often missed as breweries are either unaware that the opportunity exists, or in a rush to dispose of their waste (typically at great cost).

System options

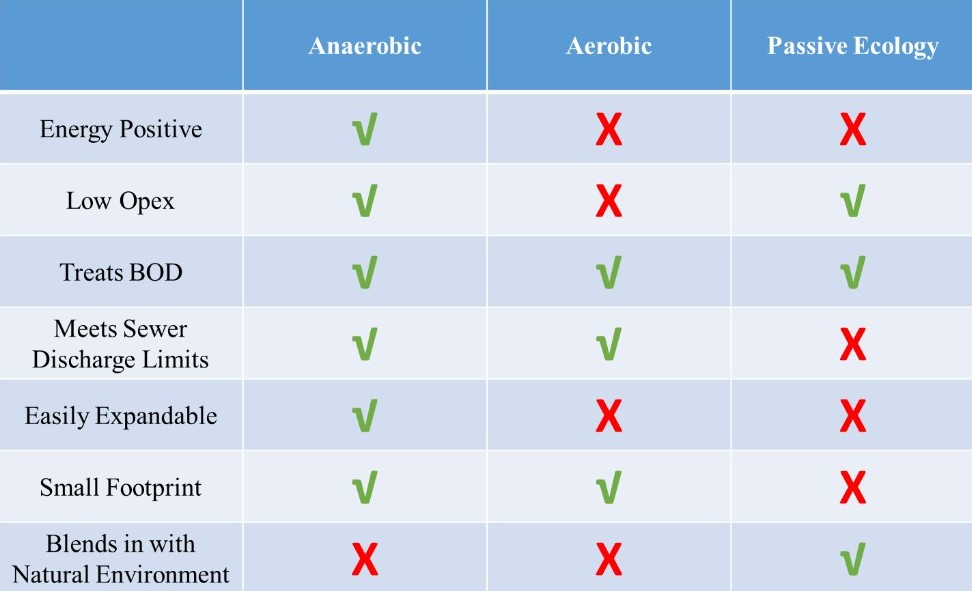

Breweries can leverage an assortment of technologies to take advantage of their various by-products. Primary selection criteria are cost, complexity, efficiency, footprint and environmental benefit. Passive ecological designs use planted fields or ponds to process the organic compounds in wastewater and occasionally produce marketable crops. These systems are relatively low cost but fail to capture the vast majority of trapped value and require a massive footprint.

Aerobic treatment systems effectively treat wastewater to required standards, need less space than agricultural alternatives and require less capital expenditure than anaerobic alternatives. However, they produce a great volume of solid waste, generate significant operational costs as a result of energy-intensive aeration and, again, do little to recapture any value.

Lastly, anaerobic digestion (AD) systems, while requiring the highest up-front capital investment, efficiently clean wastewater, require even less space, generate 90 percent less solid waste than their aerobic counterparts and produce renewable, energy-rich biogas, creating electricity with cogeneration systems.

System-level technology comparison

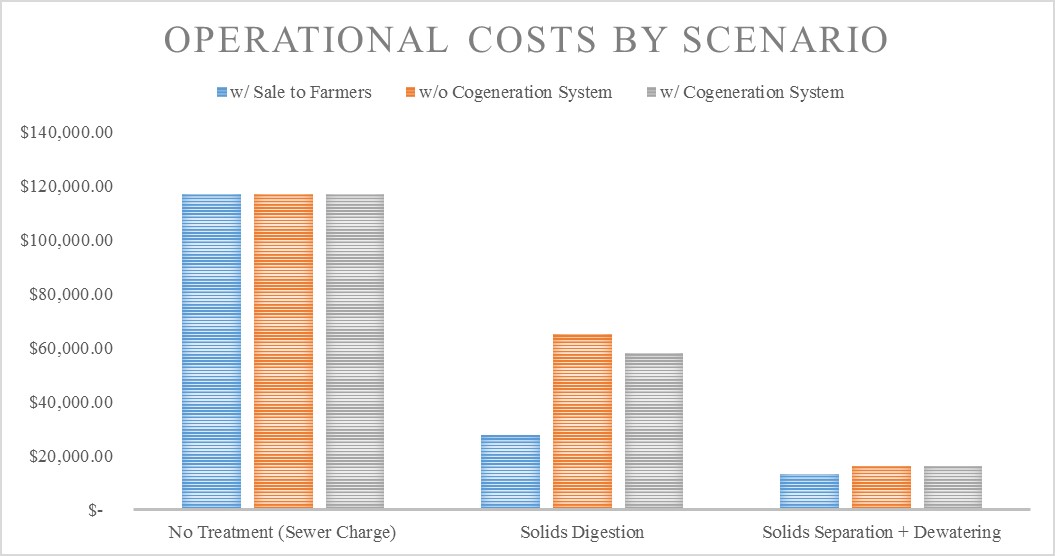

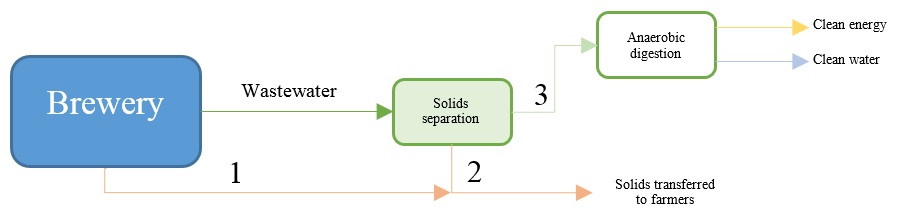

Anaerobic systems can be broadly separated into two categories: completely-mixed anaerobic digestion (fluids and solids treated together) and high-rate anaerobic digestion (solids are removed, and the soluble stream is treated). Based on in-depth economic analyses of representative craft breweries, the most comprehensive and economic way to treat brewery by-products is to separate out the solid waste from the soluble, sell or transfer the solids and treat the soluble waste in high-rate AD systems.

As shown in the operational cost chart below, solids digestion produces more waste and has a higher operating cost than solids separation and dewatering.

Operational cost by solids disposal comparison

By separating solid waste from soluble waste in effluent streams, breweries can more easily achieve high-rate anaerobic digestion, lowering energy and footprint requirements when compared to other anaerobic treatment solutions. Completely mixed ADs and upflow anaerobic sludge blanket (UASB) systems require average hydraulic retention times (HRT, the amount of time wastewater spends in the reactor) of 15 to 20 days and 6 to 8 days, respectively.

Cambrian Innovation’s EcoVolt requires only 1 to 2 days HRT, demanding less energy for pumping and mixing, and allowing for a smaller footprint. A typical brewery, producing 30,000 gallons of wastewater per day at 8,000 mg/l of biochemical oxygen demand (BOD), would require a 20 foot tall completely mixed AD covering 3,000 sq ft, a typical UASB digester at approximately 1,600 sq ft, or an EcoVolt at only 450 sq ft.[i]

Value extraction

The brewery by-products from which value can be recaptured fall into three general categories:

- Spent grains

- Recoverable solids

- Soluble waste

Nearly all breweries successfully separate their spent grain resources. Breweries collect spent grain isolated from the wort during lautering and either sell or give it to local farmers. Few breweries, however, successfully extract the remaining recoverable solids and fewer still capture the value locked in their soluble waste. While brewers do isolate the trub (spent hops and other detritus) during the whirlpool process (and/or with a hopback), this material is frequently disposed of in the sewer, at high cost, after minimal secondary solids separation.

To both avoid associated costs and open the door to high-rate AD, breweries should use highly effective solids separation technology. Separation can occur within each waste stream concurrent with the brewing process or at the conclusion of the process using a combined stream.

There are a couple technologies that have distinguished themselves from the rest. Both GEA and Alfa Laval have topline centrifugal separation systems that are ideal for brewery by-products, and BKT’s FMX filtration process has also proved very effective. Recovered solids can be combined with spent grains and transferred to farmers or ranchers, eliminating discharge costs and providing value to other producers.

With solids now separated, soluble waste is left and ready to become a revenue generator. This waste can be discharged directly to the sewer, treated on-site, or hauled off-site to abide by local regulations. Further costs can be incurred by high discharge volumes and contaminant concentrations that can overload the local wastewater treatment plant. By treating on-site with high-rate anaerobic digestion, wastewater can be converted into clean energy and clean water. High-quality, renewable biogas and reusable water provide immediate value to the brewery.

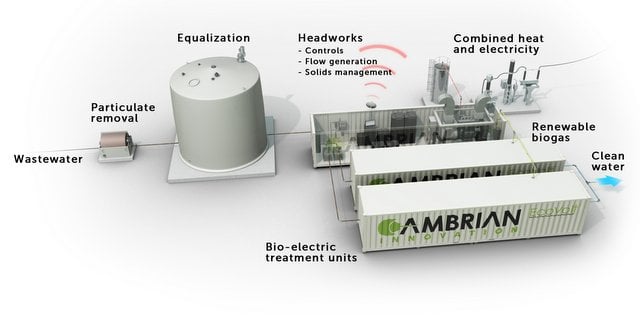

Cambrian Innovation’s EcoVolt system is the world’s leading bioelectrically-enhanced anaerobic treatment system. This modular solution efficiently harvests high-quality (80 to 90 percent methane) biogas, reduces BOD concentrations by over 80 percent (over 99 percent plus with a bolt-on purification module), and utilizes an automated remote operation system. With a full installation, extracted energy and reusable water are available for immediate use, minimizing on-site energy and water demands. By-products of this process, which are minimal, are removed biannually and used as quality fertilizer. Prefabricated and ready-to-ship systems can be easily installed allowing for rapid deployment and commissioning.

With water security declining and the cost of waste disposal rising, the intrinsic value in wastewater will pave a path forward for long-term and stable growth. Cambrian’s comprehensive solutions can eliminate volatility from the business equation for industries across water-strapped states. As breweries evaluate by-product management, they do not have to compromise on cutting costs and increasing production. Solids separation beyond the universal minimum and subsequent water treatment catalyzes resource recovery. With this approach, breweries can effectively produce clean water and clean energy while minimizing footprint and maximizing return on investment and sustainability.

[i] Tchobanoglous, George. Wastewater Engineering Treatment and Reuse, Fourth Edition. New York: McGraw Hill, 2003. Page 1009, Table 10-13.

William Dean is a business development intern at Cambrian Innovation, a provider of advanced biotechnology products for industrial businesses. Dean holds his B.A. in chemistry from Harvard University and enjoys playing ultimate frisbee and experimenting with the art of homebrewing in his free time.

RT @mrsilv: Great piece William! https://t.co/D0KXPQAFVZ

Great piece William! https://t.co/D0KXPQAFVZ

Ryan Hamilton liked this on Facebook.

Robert TheException Moreland liked this on Facebook.

Joël Back liked this on Facebook.

Jordan Wangler liked this on Facebook.

Jeremy Finkenstadt liked this on Facebook.

Lisa Sullivan Hamann liked this on Facebook.

RT @CraftBrewingBiz: White paper: Optimizing brewery wastewater and spent grain management. http://t.co/Hz0PbT2iWd Awesome @CambrianInno

Pilot Malt House liked this on Facebook.

Brew and Be Covered liked this on Facebook.

RT @CraftBrewingBiz: White paper: Optimizing brewery wastewater and spent grain management. http://t.co/Hz0PbT2iWd Awesome @CambrianInno