Clean beer is tasty beer

Planning a piping system that could efficiently transport beer from the main brewery to the packaging building took some thought. According to Kade Miller, a brewer also in charge of quality control and maintenance at Avondale, 15- to 30-bbl stainless-steel conical fermentation vessels and bright tanks in the main brewery are joined to approximately 300 feet of 2-inch Aquatherm SDR 11 non-faser Green Pipe that runs to a holding tank in the smaller packaging building.

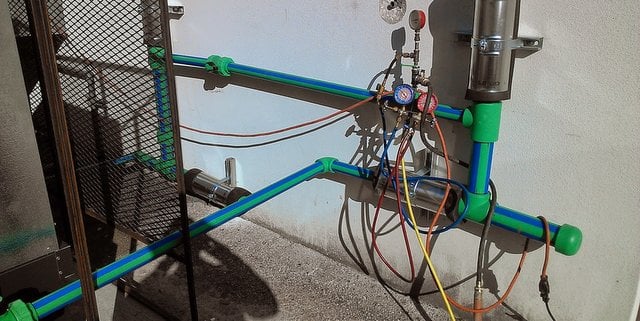

The pipe runs from the vessels and tanks in the main brewery through a wall connection, continues along the outside of the building, then stretches underground all of the way to the packaging building, routes above ground outside and through another wall connection into a storage tank in the packaging building that holds the beer until it’s ready to be transferred into kegs, cans or bottles.

Aquatherm Green Pipe is recognized for its high level of performance and low environmental impact; it is designed specifically for potable-water applications, including hot- and cold-water supply. Although its many features make the piping ideal for a range of operations, its NSF listing for potable-water and food-service applications was top of mind for this project.

Once the beer is transferred from Point A to Point B — which, according to Miller, happens a couple of times a week — Five Star low-foaming Saniclean sanitizer is pumped through the piping in reverse to catch any debris that might be stuck on a joint and completely sterilize the piping. Miller says the piping also is filled with the sanitizer when not in use. Miller feels there is no reason to worry about bacteria growing in the piping system.

“Being that [the Aquatherm Green Pipe] is food-grade material, it should not be susceptible to harboring bacteria, and with proper cleaning and sanitation should perform flawlessly,” Miller said.

Fusion takes the fear out of leaks

Because the Lake brothers had previously used Aquatherm piping systems in their brewery, constructing the new beer-transfer system was relatively easy. Esleck trained five employees on Aquatherm’s unique heat-fusion process, but, according to Miller, only two were needed to do the majority of the welding on the new project.

Aquatherm piping uses reliable heat fusion to form connections; heat fusion bonds both sides of a joint into a single, homogenous material without the use of chemicals or mechanical connections, which eliminates systematic weaknesses and potential fail-points in the pipe. The seamless heat-fusion connections, combined with the piping’s resistance to corrosion and abrasion, help to ease leakage concerns.

The installers used a McElroy Socket Fusion Kit purchased for the new project as well as a Ritmo tool that had been used on the brewery’s glycol-cooling system.

“For some reason, these guys take to [the Aquatherm fusion-welding process] very well,” Esleck said. “I think it’s a pretty complicated procedure to make beer; so maybe they’re used to more technical stuff. They could really see the fusion process when you explained it to them. They understood it and took to it more quickly than other folks I’ve tried to train.”

Although it took three days in November 2014 to install the system, Esleck said most of that time was spent digging the ditch in the ground where the piping was to be placed.

The biggest concern about the beer-transfer system was the short lengths of pipe that were exposed to the elements above ground. To ensure the beer wouldn’t freeze — no matter the weather — Esleck suggested Armaflex closed-cell insulation as well as electrical heat tracing.

“Heat tracing looks like an extension cord you wrap around the pipe,” Esleck said. A thermostat regulates the heat tracing, turning it on when the outside temperature reaches a setpoint and warming the pipe, guaranteeing the beer won’t freeze.

Although stainless-steel pipe could have been used for the project, Esleck said the Lake brothers saved a great deal of money using Aquatherm piping systems, only spending about $3,000 on materials. Labor also was an issue.

“If you are putting stainless together, you have to have a specific welder, and they certainly didn’t have that,” Esleck said. “But they did have Aquatherm-certified welders.”

Ready for another round

The project was successful, and now the Lake brothers can rest easy knowing their beer supply is clean, pure and safe in transit. “I’m pretty confident in [the Aquatherm Green Pipe] not leaking, even in the case of a substandard weld,” Miller said.

Esleck continues to keep an eye on the brewery and is excited to see what’s next for Coby and Hunter Lake. “It has been neat to watch Avondale grow,” Esleck said. “And I get to watch [the brothers] live their dream.”

As they say at Avondale Brewing, “Trunks up!”

Barry Campbell is the vice president of advertising and media relations with Aquatherm, based in Medina, Ohio. Before graduating from Ohio University’s E.W. Scripps School of Journalism with honors, Campbell had already launched a professional writing career as a reporter and working for the Associated Press. As Aquatherm’s VP of marketing, Campbell works to educate North America about the benefits of polypropylene-random pipe for P/HVAC and industrial applications.

Avondale Brewing banks on Aquatherm, polypropylene pipe http://t.co/0v90NH1Yt8 via @craftbrewingbiz

#CraftBeer #CraftBrewing #Beer #BeerBiz Avondale Brewing banks on polypropylene-random pipe for transferring signa… http://t.co/KLh1fL5Fzn