Early in 2014 we declared quality assurance the issue of the year and posted a bunch of stuff on the topic. But now it is 2015, so time to move on to another issue, right? Wrong! At every station along your line, in every nook and canning, there is a potential disruptor to quality. Literally, the very environment we live in is an enemy of quality. Every organism on earth is sown with the seeds of your beer’s destruction. (Too far?)

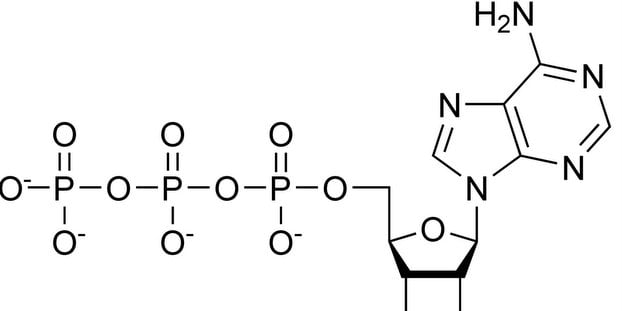

Specifically, in that last diatribe, we are talking about adenosine triphosphate (ATP). This fella lives in all living cells as a universal unit of energy. ATP is the key to all of the metabolic processes under the sun, such as photosynthesis or muscle contraction or (ahem) fermentation in yeast. This integral building block of life on earth is something to behold, for sure, but as a brewer, it must be sniffed out and eradicated, as its presence is an indication of insufficient or improper cleaning. Nothing personal, ATP. We all still appreciate these muscle contractions.

ATP Monitoring

We sent a list of questions about quality assurance to several craft brewing QA managers, and in every response we received, regular ATP monitoring was near the top of the “must do” list. (Not that a quality assurance manager can really choose a “must” among all of the QA responsibilities. It’s like choosing a favorite child or Beatles song.) Successful ATP monitoring techniques can prevent cross contamination or the growth of allergens/bacteria, ensure product integrity and improve shelf life.

“With an ATP meter I am able to instantly verify a cleaning regimen in a given area. If I see an undesirable result, we are able to address it immediately,” said Thomas Erwin, lab specialist at Real Ale Brewing Co. “We have changed quite a few cleaning protocols due to the results we were able to get using an ATP meter.”

After you’ve cleaned your equipment, but before you’ve sanitized it, it’s time to monitor for ATP — to assess just how clean these surfaces and vessels are after the cleaning process. Sanitizers are less effective if the surfaces aren’t as clean as they should be. But if this isn’t possible in your operation, sanitizers should have no effect on the accuracy of your ATP monitoring.

ATP Testing

ATP testing is performed by swabbing the surface of an item and inserting it into an ATP meter. Fifteen seconds later, you will have your answer. Easy.

ATP testing is pretty straightforward and requires a moderate upfront cost for the detection meter (between $1,400-$2,000) and then a continuing cost for the swabs (a couple bucks per). Some meters can be charged while others run off AA batteries.

The craft brewers we spoke to all used ATP monitoring equipment from Hygiena.

How much ATP is too much?

ATP is measured in relative light units (RLU), which are obtained from the number of photons produced from ATP reacting with Luciferin. The more ATP on the swab, the more photons were created, so the lower the RLU the better. The more ATP present on the swab, the more photons are created. If the RLUs exceed the specifications, then the item must be cleaned again and then swabbed again until the RLUs are within an acceptable range.

“The information is stored and can be reviewed easily on a computer,” said Kate Devine, QA, lab manager for Left Hand Brewing. “This allows for quick identification of problem areas or individuals who need to be more thorough in their cleaning practices.”

We direct you to this handy instructional video from Hygiena on the acceptable limits of ATP.

Using the Hygiena as our example, 0-10 RLU is the general limit for a passing grade, and 11-30 RLU is considered a “caution” area. Anything greater than that is a fail, but these limits are customizable in several ways.

For one, you might want to eliminate a “caution” zone and consider anything that’s not a pass to be a fail. Second, the general limits don’t apply in every situation. Surfaces that are easier to clean, such as stainless steel, might have lower RLU limits, whereas equipment such as conveyer belts that are harder to clean may have higher RLU limits. Surfaces that are in direct contact with products should have stricter standards than those with indirect contact.

When collecting ATP samples and conducting tests, be aware that sunlight can distort results and increase RLU readings, and an ambient temperature of 70-72 degrees F is optimal for the best results. Low temperatures, such as when tests are just removed from a refrigerator, can also skew results. The only time ambient temperatures can affect results is if reagents are at a low temperature. This can happen if testing is done immediately after taking the tests out of the refrigerator. The measuring devices themselves can operate in colder environments, but they will need to recalibrate upon detecting a colder ambient temperature.

In this new year, if you aren’t already, now is the time to commit to a strict and consistent ATP monitoring program. Your beer and your customers will thank you.

swagnerrobinson says

I just found a site that has a bunch of info on ATP testing, here: http://livewelltesting.com/knowledge-center/all-about-atp

They sell testing equipment too: http://livewelltesting.com/brands/Hygiena.html

Quality assurance basics: ATP monitoring, testing http://t.co/4eqGcFVR3O via @craftbrewingbiz

How do you guarantee equipment is clean? Test for organic matter (ATP) – “Quality assurance basics” http://t.co/cEwSUYlInA @CraftBrewingBiz

Quality assurance basics: ATP monitoring, testing http://t.co/4ZJrYxHrA2

Quality assurance basics: ATP monitoring, testing http://t.co/Lnz2wNXwkf via @craftbrewingbiz