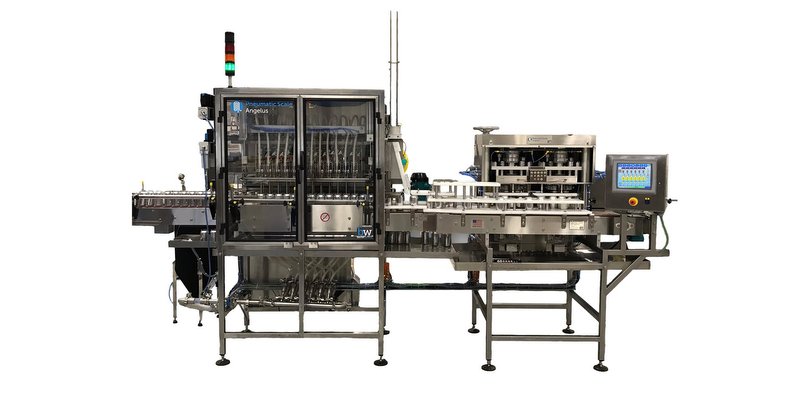

AtmosZero is on a mission to electrify steam and become the first to manufacture industrial steam heat pumps in the United States. AtmosZero is opening its first 100,000 sq-ft manufacturing factory at the Forge Campus in Loveland, Colo., as a step to commercializing its “Boiler 2.0,” (seen above). Fellow Coloradoans at New Belgium Brewing are set to become an early adopter.

“We are laser focused on manufacturing a product that is modular, scalable and can be deployed today – not in decades,” said Addison Stark, CEO and co-founder of AtmosZero, which was named Cleantech Group’s Early-Stage Company of The Year in January.

The idea behind Boiler 2.0 is to replace fossil-fired industrial boilers with a drop-in electrified heat pump boiler designed specifically to deliver low-cost decarbonized steam

Here’s a look at the schematics of the New Belgium Brewing installation, coming this spring, with a formal ribbon cutting planned for the summer. Stay tuned.

AtmosZero Boiler 2.0

AtmosZero recently produced its first commercial-scale Boiler 2.0 product at the AtmosZero factory. This facility will manufacture up to 100 Boiler 2.0 units per year and will begin commercial shipments in 2026. To support the ramp-up of its manufacturing capabilities, AtmosZero was allocated up to $24.3 million for the Qualifying Advanced Energy Project Credit (48C tax credit) by the U.S. Department of Energy and Treasury Department. AtmosZero says its expanded manufacturing footprint should support upwards of one gigawatt of steam.

The AtmosZero team says Boiler 2.0 aptly provides 2x the efficiency by using half the electricity of today’s electric boilers.

How it works…

- Proprietary technology extracts heat from the air

- Because heat is upgraded and not created, efficiencies can be significantly higher than 100%, slashing facility energy needs

- Can be water-sourced and integrate with your process cooling loop

- AtmosZero’s Boiler 2.0 uses novel steam-generating heat pump technology, packaged into a drop-in electrified boiler solution

- All-in-one process avoids the complexities, costs, and down-time of integrating a traditional waste-heat heat pump system, resulting in a more cost-effective and scalable solution

In addition to growing U.S. industrial manufacturing, the AtmosZero factory will represent a major economic boon to the greater Northern Colorado area.

To oversee the build out and expansion of the company’s manufacturing capabilities, AtmosZero appointed Jim Barnhart as chief operating officer. In his role, Mr. Barnhart will scale AtmosZero from low-volume manufacturing to mass deployment of the Boiler 2.0 technology.

“AtmosZero is at the forefront of American industrial innovation in the heart of Colorado,” said Jim Barnhart, COO of AtmosZero. “Steam touches everything in our lives from cosmetics to food and beverage to pharmaceuticals and more. Our Boiler 2.0 technology is key to enabling US industry and beyond to rapidly and cost-competitively reduce global emissions.”

Previously, Mr. Barnhart was senior vice president of operations at Nanometrics Inc., overseeing advanced process control solutions, and senior vice president of global operations at Cymer LLC, where he guided large-scale operational initiatives. Mr. Barnhart’s foundation in collaborative leadership began as a nuclear engineering division officer in the U.S. Navy, where he developed technical expertise and operational rigor.

“AtmosZero is opening the first American factory to develop industrial heat pump technology using American innovation,” said Michael Schwartz, retired Daikin Applied Americas President and CEO and AtmosZero board member. “We are thrilled to welcome Jim and his decades of operational experience to the leadership team and are incredibly excited about this next phase growth in bringing a cost-effective electrified solution to boiler rooms around America and the world.”

Leave a Reply

You must be logged in to post a comment.