Control of the brewing process is one of the keys to consistently creating quality craft beer. But with variables ranging from dissolved oxygen, pH and gravity to pressure, temperature and conductivity, knowing exactly what’s happening inside the tank has historically been part random sampling and part guesswork. Repeatedly testing the beer during the fermentation process has been one of the few ways for brewers to collect important fermentation data. However, relying on sampling as quality control only provides a snapshot of visibility into the product’s condition.

Fortunately, technology advances are taking the guesswork out of fermentation and brewing. A company that consistently catches our eye is Precision Fermentation. Its BrewMonitor System replaces ad hoc sampling and testing with fully automated, continuous fermentation monitoring. How does it work?

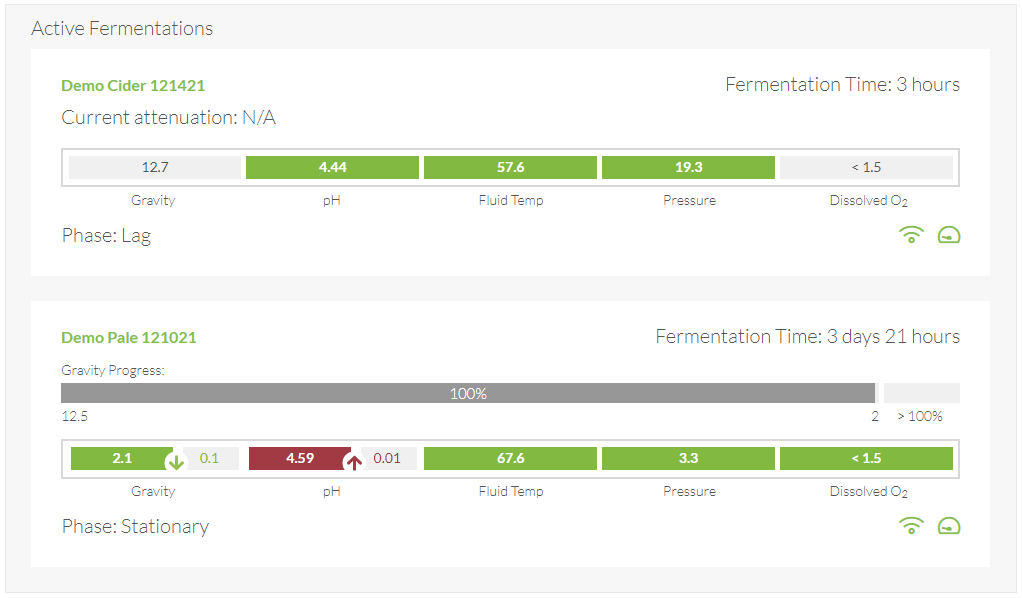

The BrewMonitor Sensor Hub (this thing), which attaches easily to any fermentation tank, collects and live-streams critical active-fermentation information and alerts to a PC, tablet or smartphone. This gives brewers the real-time visibility needed for consistent product quality, less waste and more efficient production.

The BrewMonitor System measures and benchmarks temperature, ambient temperature, pH, conductivity, gravity, pressure and dissolved oxygen. Automatically triggered email and/or text alerts based on custom thresholds notify brewers about problems before it’s too late.

The BrewMonitor System’s pre-built dashboards transform fermentation tanks into a powerhouse of insight. Benchmarking informs future brews and improves batch-to-batch consistency, while the ability to view historical data accelerates yeast vitality assessment for more timely repatches and prevention of stalled fermentations.

And, the Brew Monitor System is cloud-based, so there’s no software to install.

Craft brands including Georgia’s Terrapin Beer Co., Washington’s Western Red Brewing and North Carolina’s Bond Brothers Beer Co. use BrewMonitor. From a previous story on the BrewMonitor System:

“The features in BrewMonitor System definitively address two of the most critical aspects of brewing quality assurance,” said Jared Resnick, founder and CEO of Precision Fermentation. “The first is faster access to the most crucial day-to-day fermentation data. The BrewMonitor dashboard was developed with extensive customer feedback, as we wanted to be sure we were hitting the mark with the exact information that brewers, QA personnel and business owners need — on-demand and with as little friction as possible. The second is automating the transformation of raw data into actionable fermentation insights. For example, the Brand Analytics module looks at all fermentations for a given brand, performs the analysis, and at a glance, indicates exactly where new batches might be going right or wrong. The refinements in this new release are an important milestone in our continuing mission to drive the leading edge of brewing automation and quality management, helping brewers streamline operations and freeing them up to create more great products.”

Learn more about Precision Fermentation and the BrewMonitor System by clicking right here.

Leave a Reply

You must be logged in to post a comment.