Water quality is at the forefront of brewing. Not only do craft brewers use water to make their delicious beer products (in millions of barrels per year), but the sanitation of wastewater effluent is an enormous part of the environmentally conscious brewing business. Cleanliness is one of the major credos in the craft industry’s portfolio of environmental stewardship, but despite significant improvement over the last 20 years, water consumption and wastewater disposal remain environmental and economic hurdles. Just check out this article on the subject over at The Press Democrat:

“From an operational standpoint, it, along with a handful of other pieces of equipment, is the first thing I check in the morning,” said Vinnie Cilurzo, brewmaster at Russian River Brewing Co. in Santa Rosa, of his underground waste treatment system, which cost about $100,000. “If your wastewater is not operable, your brewery is not operational.”

Many craft breweries have needed to find innovative solutions for water and wastewater management. Why? Sometimes small cities can’t compete with a growing craft brewery’s wastewater needs. In Petaluma, Calif., Lagunitas Brewing Co. spends more than $1 million per year to ship its wastewater to Oakland for treatment at the East Bay Municipal Utility District plant since the Petaluma plant can’t handle the volume and strength of the waste it produces, according to that Press Democrat article. Because of that, Lagunitas is considering buying its own $8 million water treatment plant.

Given these pressing concerns, new and old brewers need to be mindful of the future risks of cost and supply when it comes to wastewater. While the average water use ratio for a brewery is around 7 barrels (bbls) of water to 1 bbl of beer, many craft brewers are world leaders with ratios below 3 to 1 bbl. Those numbers come from the Brewers Association, which is a great resource with its Water and Wastewater: Treatment/Volume Reduction Manual. This manual is a consolidated resource for effective water and wastewater management solutions in the craft brewers segment. Solutions outlined can apply to all breweries, regardless of location and operational size.

Wastewater pre-treatment is an important investment for green-conscious craft breweries. Reducing BOD and TSS from the waste stream leaving the brewery before it enters the municipal system is important. Biological Oxygen Demand (BOD) is a measure of how much oxygen it takes microorganisms to break down soluble organic material in water. More BOD equals less oxygen in water for plants and animals and more work for city wastewater systems. Total Suspended Solids (TSS) is the total amount of solids in water. Bacteria consumes these solids.

Also, let’s not forget about heavy metals, fats, oils and grease (FOG) or Chemical Oxygen Demand (COD), where certain chemicals such as reducing agents will react with oxygen. There’s a great article on Birko’s website that details all of these wastewater categories; Birko is a leader in providing food safety solutions for the protein processing, food and beverage industries (including craft).

Fortunately, the days of dumping whatever you want down the drain are numbered, especially in the bigger cities that have older wastewater treatment facilities and smaller cities that can only handle so much effluent. We quote the aforementioned The Press Democrat article:

It mostly has to do with what’s left over after brewing the beer: sugar, yeast and proteins. None of it is toxic, but in high concentrations, it can play havoc with the microbes used by sewage treatment plants to break down organic waste. “It’s not metals, it’s not chemicals and toxins and stuff,” [Lagunitas owner Tony] Magee said. “It’s just food. Lots and lots of bug food.” Pouring too much of the stuff into the waste stream can wind up overfeeding the bacteria, causing them to suck all the oxygen out of the water and killing the microbes.

One component of the waste in the brewing process is known as trub (protein and hops left in kettle) , which is separated from the grains boiling process resulting in waste with significantly high total solid concentrations. This waste is difficult to treat using conventional biological systems due to the high suspended solids found in the waste, so it is typically hauled away for treatment at great expense to the brewery.

If the suspended solids can be removed, conventional biological systems could be able to treat the liquid portion, reducing treatment costs and even provide added revenue from the sale of the separated grains as an animal feedstock (though many craft breweries just give it away). While spent grain or trub and yeast slurry can be combined and sold as cattle feed, spent diatomaceous earth (DE) can be sent to local organic farmers for use as a soil amendment. We suggest you check out our recent article on cows chowing on craft brewing mash here.

So how does the wastewater pre-treatment process work? Most folks will categorize biological treatment systems into two categories — anaerobic (without oxygen) and aerobic (with air/oxygen supply). Anaerobic treatment is characterized by biological conversion of COD into biogas — mainly methane and carbon dioxide. During aerobic treatment (air) oxygen is supplied to oxidize the COD into carbon dioxide and water. Both biological processes produce new biological biomass (biosolids). Each system has different uses along with pros and cons. There is a great white paper called Recent Developments of Brewery Effluent, which explains both systems in major detail. We suggest you read it.

These wastewater systems and technologies are vast and complex. There are many applications: side streaming, pH equalization, aeration, settling and pumping out. There are also many unique systems, technologies and chemicals with names like digesters, filter bags, sludge bed reactors, stirred tank reactors, coagulation/flocculation chemicals, aerated stabilization basins and centrifugal separating technologies. Big corporate companies like Birko, GEA, Siemens and a host of local and regional players with names like Natural Systems (Santa Barbara, Calif.), Specific Mechanical Systems (Victoria, Canada) and Consolidated Treatment Systems (Franklin, Ohio) can help you figure out which process is best for your operation.

Craft brewers will need this help as the industry is constantly changing. For instance, an onsite wastewater treatment facility can not only pre-treat the brewing waste to reduce solids before release in the city sewer, but also the methane generated in this process can be captured and used to co-generate electricity at the brewery. Another innovative example: Back in May, Oregon BEST awarded a commercialization grant to a start-up company launched by a pair of Oregon State University (OSU) researchers teaming with one of Oregon’s largest beer breweries to test a microbial fuel cell that could help the brewery simultaneously clean its wastewater, generate electricity and reduce the amount of water it sends to the city for treatment.

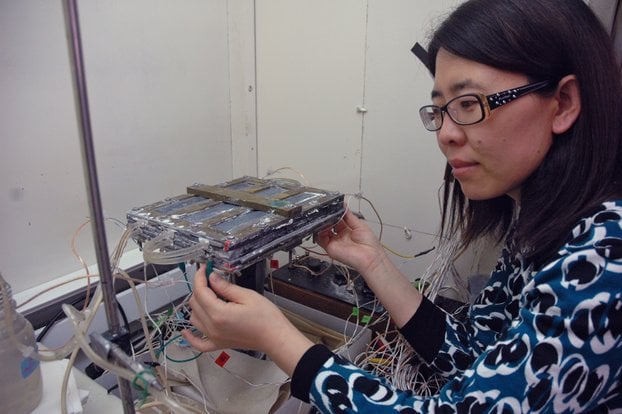

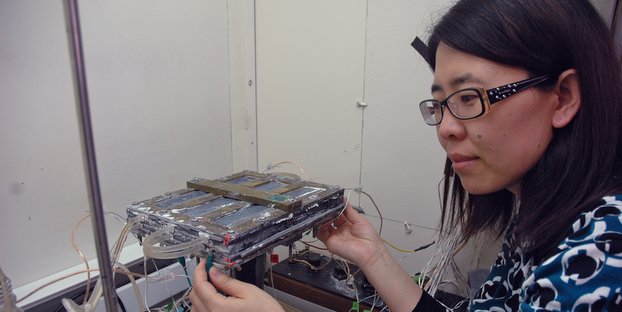

The startup, Waste2Watergy, is partnering with Widmer Brothers Brewing in Portland. Because brewing is a water-intensive industry, its wastewater contains an optimal mix of organic ingredients for the microbes in the fuel cell and the company pays a significant amount of money annually to the City of Portland to treat its wastewater. From our previous story:

“We chose to partner with Widmer because they are very engaged in sustainability efforts, their wastewater has an ideal mix of organic materials for our technology and they use a lot of water,” said Hong Liu, a professor in the OSU Dept. of Biological and Ecological Engineering, who co-founded Waste2Watergy with Yanzhen Fan, a researcher in the same department. “Ultimately, we want to be able to reuse the treated water after it flows through the fuel cell instead of sending it to the city for treatment.”

The patented technology uses electrodes impregnated with a proprietary combination of microbes that generate electricity when consuming organic matter suspended in wastewater. The process lowers the wastewater’s BOD level, or the amount of oxygen required by aerobic microorganisms to decompose organic matter in water. Water treatment facilities, including the City of Portland, often charge companies for treatment based on the BOD levels of wastewater.

Water usage and wastewater effluent trends are clearly topics breweries should be talking about; building a wastewater plan is a great way to start: Find information on regulatory drivers and examples of non-regulatory drivers; establish key performance indicators and goals, managing water and wastewater data and benchmarking your progress; start a best practices guide to reduce water usage and wastewater generation with a focus on opportunities in the brewing process, including packaging, warehousing, utilities, food service and events; and review the vast array of on-site wastewater treatment technologies available to craft brewers.

We’ll get into more detailed summaries of many of these issues in future features on Craft Brewing Business.

The growing challenges of wastewater control in craft brewing @CraftBrewingBiz by @KeithGribbins http://t.co/jrEoZgRqS5 #beer4water

The growing challenges of wastewater control in craft brewing http://t.co/G4v3PfwQAZ @CraftBrewingBiz by @KeithGribbins

RT @jacobsberg: The growing challenges of wastewater control in craft brewing http://t.co/6YRO2DfUA3 #beer #science via @craftbrewingbiz

RT @jacobsberg: The growing challenges of wastewater control in craft brewing http://t.co/6YRO2DfUA3 #beer #science via @craftbrewingbiz

RT @jacobsberg: The growing challenges of wastewater control in craft brewing http://t.co/6YRO2DfUA3 #beer #science via @craftbrewingbiz

The growing challenges of wastewater control in craft brewing http://t.co/6YRO2DfUA3 #beer #science via @craftbrewingbiz

RT @CraftBrewingBiz: The growing challenges of wastewater control in #CraftBrewing. http://t.co/QSdB1cCSG4 #sundayreading #Sundayreading

RT @heatheranne31: Cool article about water usage in craft brewing. http://t.co/BBraBPHRUR via @craftbrewingbiz

RT @heatheranne31: Cool article about water usage in craft brewing. http://t.co/BBraBPHRUR via @craftbrewingbiz

Cool article about water usage in craft brewing. http://t.co/BBraBPHRUR via @craftbrewingbiz